RWB II ROTARY SCREW COMPRESSOR UNITS

INSTALLATION

070.200-IOM (DEC 11)

Page 8

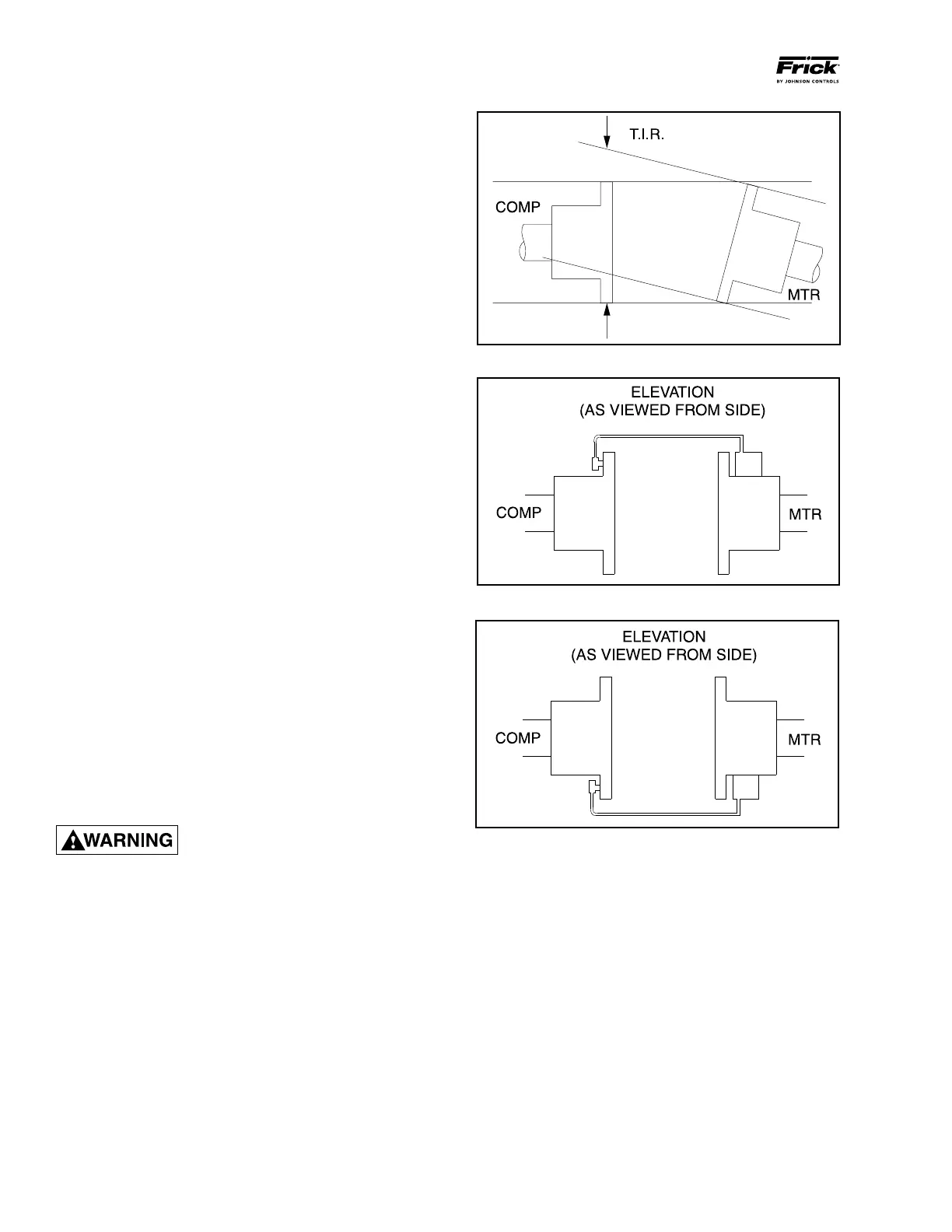

Figure 1 - Angular Misalignment

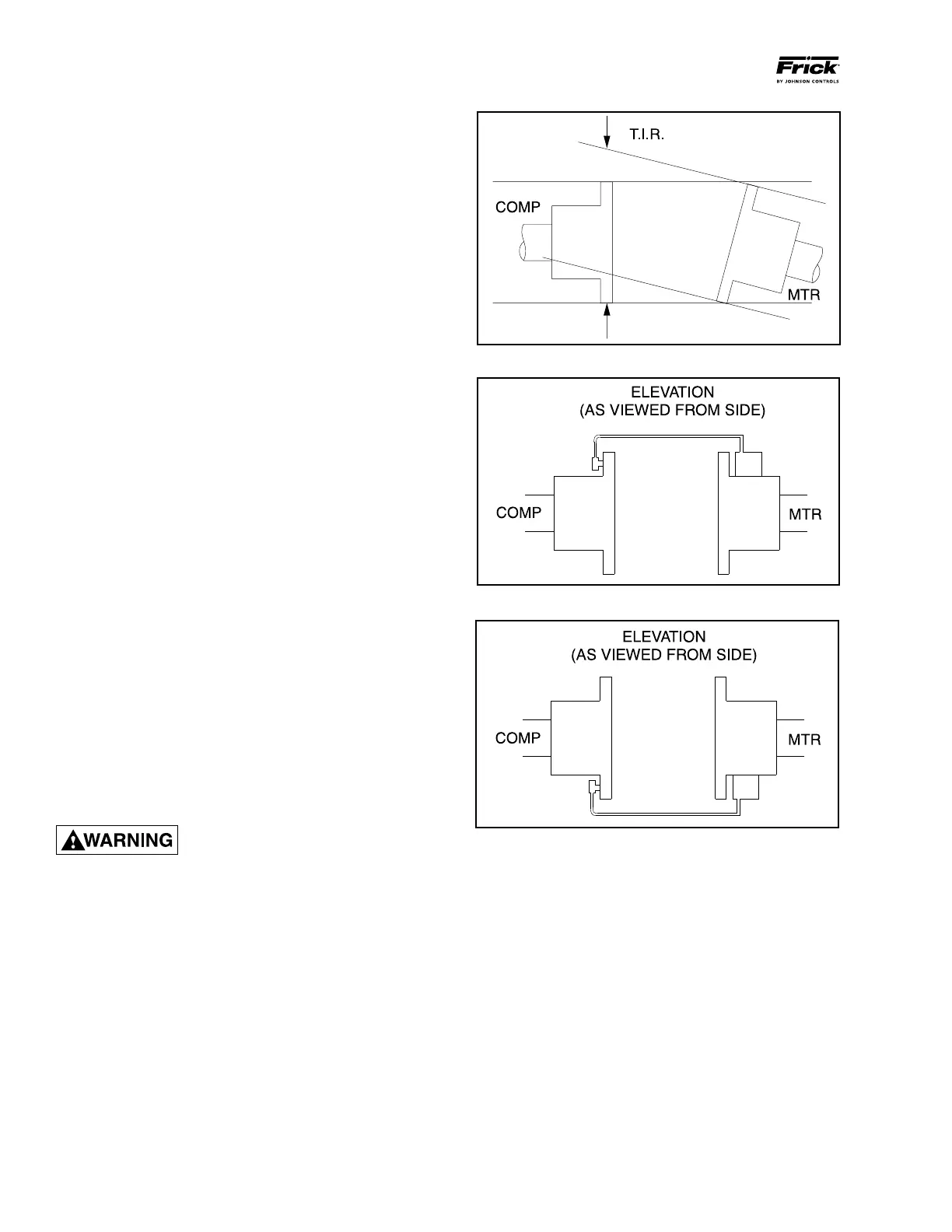

Figure 2 - Dial Indicator Attached (at 12 o'clock)

Figure 3 - Dial Indicator at 6 o'clock

3. Reassemble the coupling with the disc packs and the cen‑

ter spool. Center the coupling between the shafts and ensure

that the keys are fully engaged in their keyways. Ensure that

they are reassembled exactly as they were disassembled.

Torque disc pack hardware to specification in BP Series

Coupling Data Table.

4. Key and secure the hubs to the shafts by tightening the

clamping bolts. Make sure that the keyways are offset 180°

to maintain balance.

5. Torque the clamping bolts of both hubs to the torque value

given in the Data Table. DO NOT USE ANY LUBRICANT

ON THESE BOLTS.

6. IMPORTANT: Only after the shaft clamping bolts are

tightened to their final torque can the keyway setscrew be

tightened! If the keyway setscrew is tightened before the shaft

clamping bolts are tightened, then the hub can be cocked

on the shaft.

7. Proceed to Coupling Alignment.

COUPLING ALIGNMENT PROCEDURE

The life of the compressor shaft seal and bearings, as well

as the life of the motor bearings, is dependent upon proper

coupling alignment. Couplings may be aligned at the factory

but realignment MUST ALWAYS be done on the job site

after the unit is securely mounted on its founda tion. Initial

alignment must be made prior to start‑up and rechecked

after a few hours of operation. Final (HOT) field alignment

can only be made when the unit is at operating tempera ture.

After final (HOT) alignment has been made and found to be

satisfac tory for approximately one week, the motor may be

dowelled to maintain align ment.

NOTE: Frick recommends cold aligning the motor .005"

high. This cold misalignment compensates for thermal

growth when the unit is at operating temperature.

The following procedure is applicable to both the CH and

DBZ‑B couplings. Dial indicators are to be used to measu‑

re the angular and parallel shaft misalign ment. Coupling

alignment is attained by alternately measuring angular and

parallel misalignment and repositioning the motor until the

misalignment is within specified tolerances.

ALWAYS LOCK OUT MAIN MOTOR

DISCONNECT BEFORE TOUCHING

MOTOR SHAFT. MISALIGNMENT

MUST NOT EXCEED .004" FOR ALL CH, DBZ-B AND

SERIES 52 COUPLINGS EXCEPT DBZ-B 226 WHICH

SHALL NOT EXCEED .003".

ANGULAR ALIGNMENT

1. To check angular alignment, as shown in Figure 1., attach

dial indicator rigidly to the motor hub. Move indicator stem

so it is in contact with the outside face of compressor hub,

as shown in Figure 2.

NOTE: When DBZ-B couplings are used on motors

with sleeve bearings, it is necessary to secure the two

coupling hubs with a bolt to prevent them from drifting

apart when rotating.

2. Rotate both coupling hubs several revolutions until they

seek their normal axial positions.

Check the dial indicator to be sure that the indicator stem is

slightly loaded so as to allow movement in both direc tions.

3. Set the dial indicator at zero when viewed at the 12 o’clock

position, as shown in Figure 2.

4. Rotate both coupling hubs together 180° (6 o’clock po‑

sition), as shown in Figure 3. At this position the dial indicator

will show TOTAL angular misalignment.

NOTE: The use of a mirror is helpful in reading the indi-

cator dial as coupling hubs are rotated.

5. Loosen motor anchor bolts and move or shim motor to

correct the angular misalignment.

After adjustments have been made for angular mis align ment

retighten anchor bolts to prevent inac curate read ings. Repeat

Steps 3 through 5 to check corrections. Further adjustments

and checks shall be made for angular misalignment until the

total in dicator reading is within the specified tolerance.

Loading...

Loading...