RWB II ROTARY SCREW COMPRESSOR UNITS

MAINTENANCE

070.200-IOM (DEC 11)

Page 43

BARE COMPRESSOR MOUNTING

The following procedure is required only when a bare com‑

pressor is replaced in the field.

1. Thoroughly clean the compressor feet and mounting pads

of burrs and other foreign matter to ensure firm seating of

the compressor.

2. Clean the discharge flange surfaces on the compres sor

and separator.

3. Install a gasket on the compressor discharge connec tion

of the separator.

4. Set the compressor on its base and tighten the dis charge

flange bolts. The feet of the compressor should lift off the

mounting base. If the compressor feet do not raise off

the mounting base install a thicker discharge gasket and

reinstall the discharge flange bolts. Check the clearance

between the feet and the base with a feeler gauge. Shim the

compres sor feet (gauge reading plus .002").

5. Tighten compressor hold down bolts.

6. Complete compressor/motor coupling alignment (see

INSTALLATION section).

7. Complete tubing, piping and wiring per the P & I and wir‑

ing diagrams.

SHUTDOWN DUE TO IMPROPER OIL

PRESSURE (HIGH STAGE and BOOSTER)

The compressor must not operate with incorrect oil

pressure.

1. For units with QUANTUM™LX Control Panels, refer

to CONTROL SETUP ‑ "OIL SETPOINTS DISPLAY" in

090.022‑O.

2. For units with Microprocessor Control Panels, install a

pressure transducer to monitor the pressure of the oil supply

to the balance piston. The correct pressure with the solenoid

closed is 50 psi below discharge pressure (+/‑15 psi). The

correct pressure with the solenoid valve open is within 20 psi

of oil pressure as measured at the oil manifold.

At 60 psi and less differential pressures, with the solenoid

valve closed, the oil pressure should be 1.1 times suction

pressure (+/‑15 psi). Differential pressure is defined as de‑

fined as discharge pressure minus suction pressure.

The shutdown should occur if the condition persists for 2

minutes. For the first 5 minutes after compressor start has

been confirmed, this safety shutdown may be ignored.

3. For units with Electromechanical Control Panels, a safety

shutdown on balance piston oil pressure may be omitted.

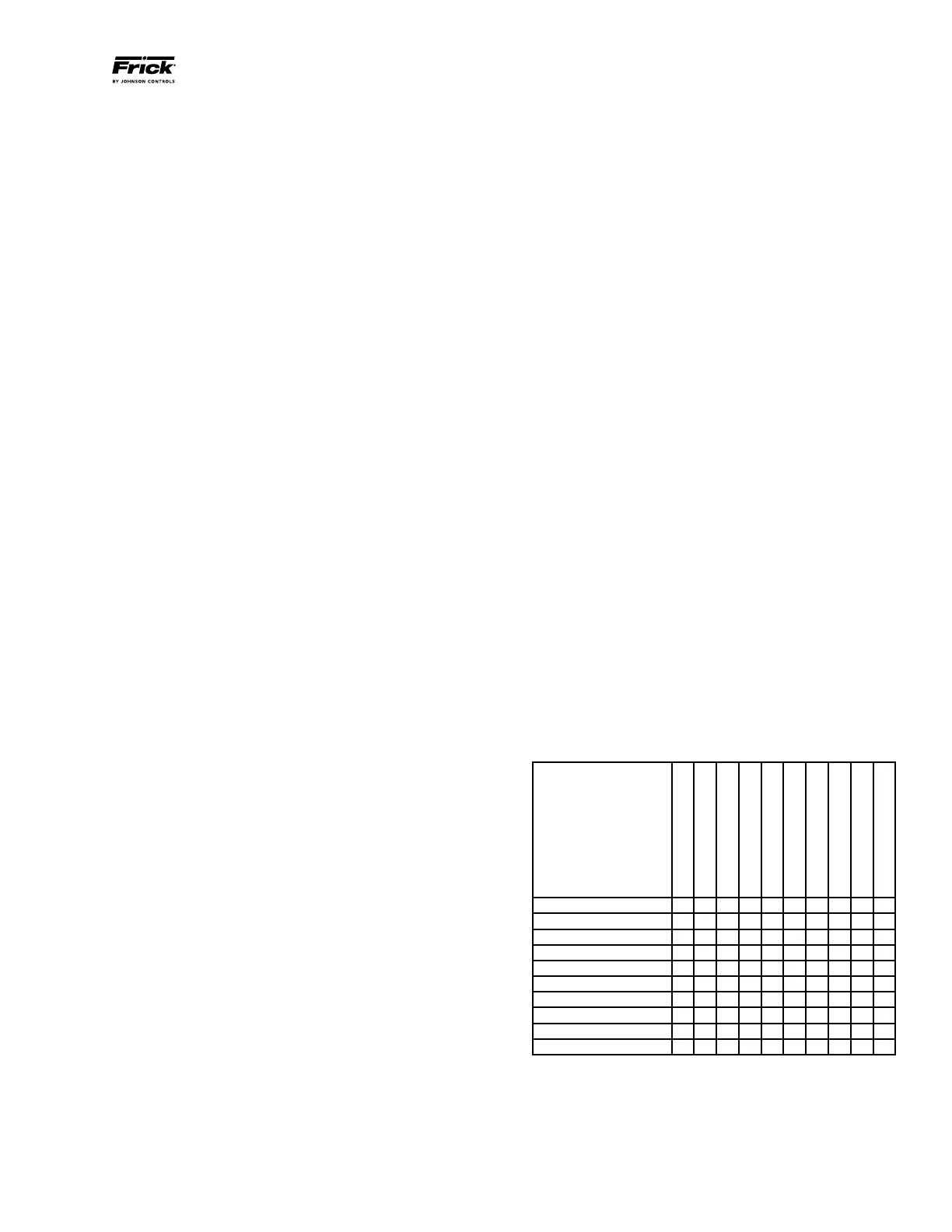

GREASE COMPATIBILITY

If it becomes necessary to mix greases, be careful not to

combine different oil bases or thickeners. DO NOT mix a

mineral oil‑base grease with a synthetic oilbase grease. Also,

a grease with a lithium thickener should not be mixed with

one containing a sodium thickener. The table illustrates the

compatibility of various types of grease based on results by

National Lubricating Grease Institute (NLGI). The chart indi‑

cates a great variance in compaibility with the greases tested.

NLGI Grease Compatibility Chart

Install the valve and adjust the spring tension accordingly

to maintain the predetermined oil temperature. The recom‑

mended oil temperature for ammonia is 130°F. Check with

Frick service for recommended oil temperatures for other

refrigerants.

If all of the above steps have been properly performed and

the desired oil temperature can not be achieved, contact

Frick Service.

Aluminum Complex

Barium

Calcium

Calcium 12‑hydroxy

Calcium Complex*

Clay

Lithium

Lithium 12‑hydroxy

Lithium Complex

Polyurea

Aluminum Complex – I I C I I I I C I

Barium I – I C I I I I I I

Calcium I I – C I C C B C I

Calcium 12‑hydroxy C C C – B C C C C I

Calcium Complex I I I B – I I I C C

Clay I I C C I – I I I I

Lithium I I C C I I – C C I

Lithium 12‑hydroxy I I B C I I C – C I

Lithium Complex C I C C C I C C – I

Polyurea*

I I I I

C

I I I I –

B = Borderline Compatibility

C = Compatible

I = Incompatible

* Standard

Loading...

Loading...