RWB II ROTARY SCREW COMPRESSOR UNITS

OPERATION

070.200-IOM (DEC 11)

Page 23

Integral control will increase the output in increments,

over time, to correct the control input to the setpoint.

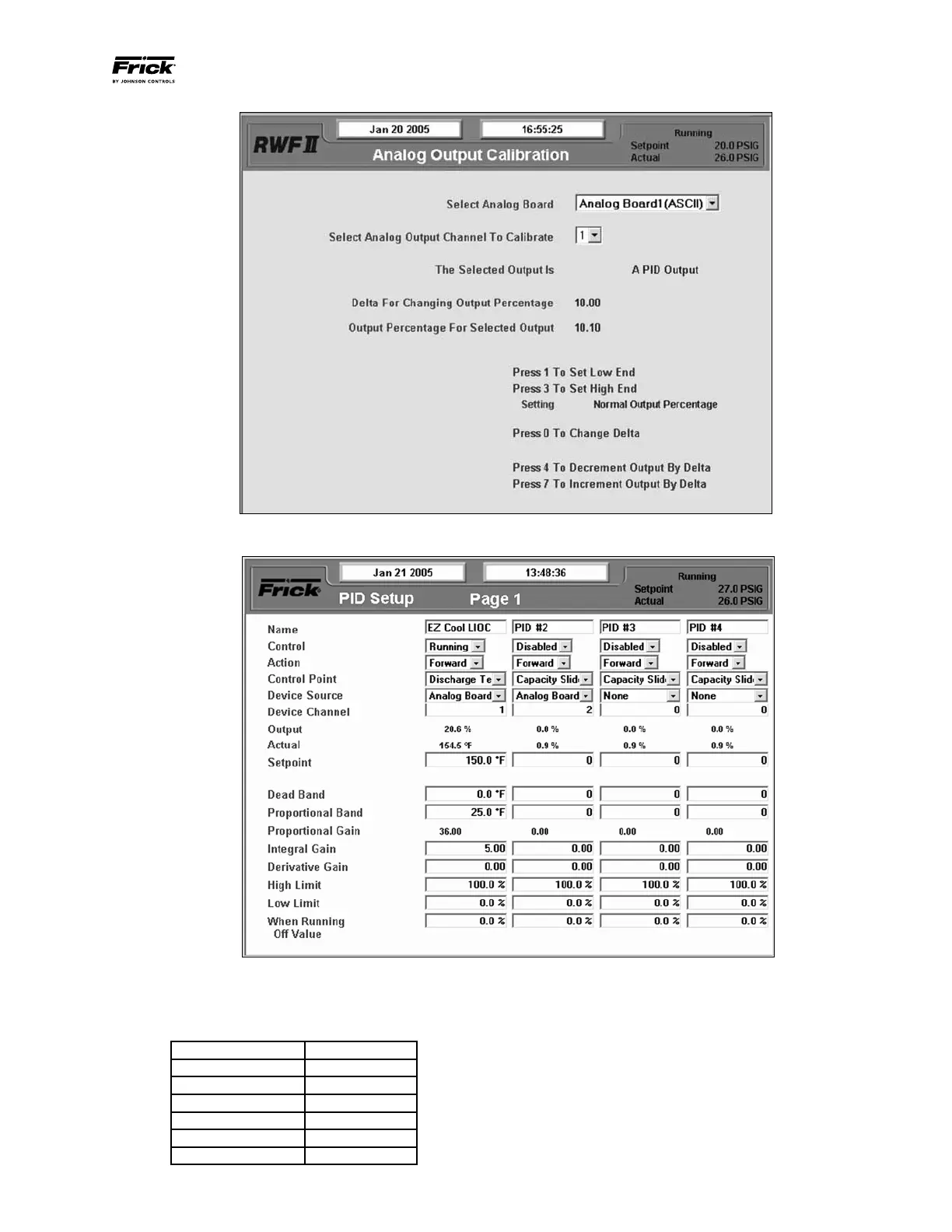

Control Input Output %

150°F 0%

155°F 20%

160°F 40%

165°F 60%

170°F 80%

175°F 100%

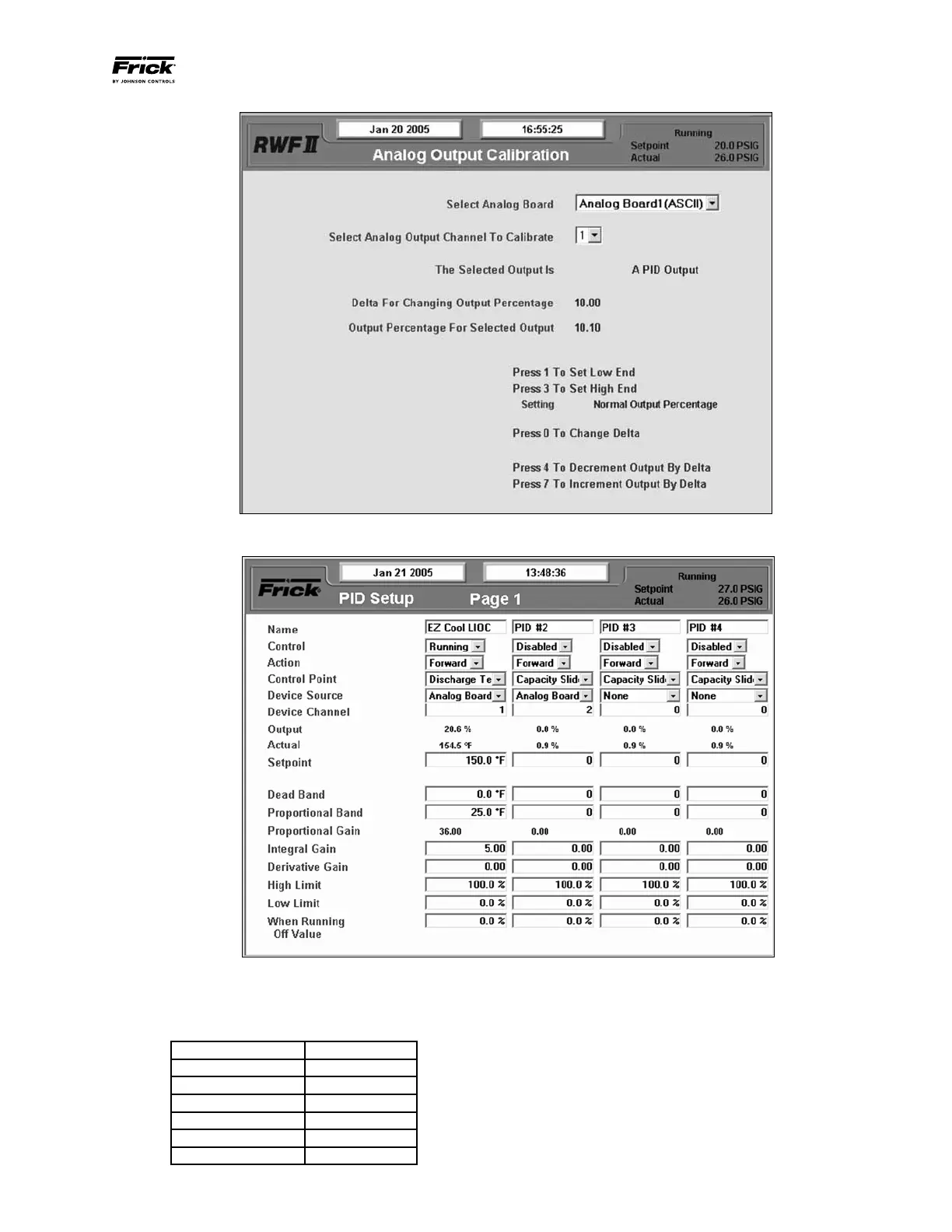

Figure 21 - Analog Output Calibration

Figure 22 - PID Setup

Based on these descriptions set PID #1 for EZ‑Cool

™

LIOC

per Figure 22 as a starting point. Tuning of the output will be

required. There should be no need to use a derivative gain.

SUCTION CHECK VALVE

Low temperature booster compressor operations require

a more positive suction check valve closure. This is ac‑

complished by allowing the high stage discharge pressure

gas to assist the spring tension and intermediate pressure

closing force.

Loading...

Loading...