RWB II ROTARY SCREW COMPRESSOR UNITS

INSTALLATION

070.200-IOM (DEC 11)

Page 13

ECONOMIZER - HIGH STAGE (OPTIONAL)

The economizer option provides an increase in system ca‑

pacity and efficiency by subcooling liquid from the condenser

through a heat exchanger or flash tank before it goes to the

evapora tor. The subcooling is provided by flashing liquid in

the economizer cooler to an intermediate pressure level.The

intermediate pressure is provided by a port located part way

down the compres sion process on the screw compressor.

As the screw compressor unloads, the economizer port will

drop in pressure level, eventually being fully open to suc‑

tion. Because of this, an output from the microproces sor

is generally used to turn off the supply of flashing liquid on

a shell and coil or DX economizer when the capacity falls

below approximately 45%‑60% capacity (85%‑90% slide

valve position). This is done because the compressor will

be more efficient operating at a higher slide valve position

with the economizer turned off, than it will at a low slide valve

position with the economizer turned on. Please note however

that shell and coil and DX economizers can be used at low

compressor capaciti es in cases where efficien cy is not as

important as assuring that the liquid supply is subcooled. In

such cases, the economi zer liquid solenoid can be left open

whenever the com pressor is running.

WATER-COOLED OIL COOLING (Optional)

The plate and shell type water‑cooled oil cooler is mounted

on the unit complete with all oil piping. The customer must

supply adequate water connections and install the two‑way

water regulating valve if ordered in lieu of a three‑way oil

temperature valve. It is recom mended (local codes permitting)

that the water regula tor be installed on the water outlet con‑

nection. Insert the water regulator valve bulb and well in the

chamber provided on the oil outlet connection. Determine

the size of the water‑cooled oil cooler supplied with the unit,

then refer to table for the water connec tion size. The water

supply must be sufficient to meet the required flow.

Frick recommends a closed‑loop system for the waterside

of the oil cooler. Careful attention to water treatment is es‑

sential to ensure adequate life of the cooler if cooling tower

water is used. It is imperative that the condition of cool-

ing water and closed-loop fluids be analyzed regularly

and as necessary and maintained at a pH of 7.4, but not

less than 6.0 for proper heat exchanger life. After initial

start‑up of the compressor package, the strainer at the inlet

of the oil cooler should be cleaned several times in the first

24 hours of operation.

* Based on 100 foot liquid line. For longer runs, increase line

size accordingly.

** For models 60 and 76, contact Frick engineering.

LIQUID LINE SIZES/RECEIVER VOLUME

Liquid line sizes and the additional receiver volume (quanti‑

ty of refrigerant required for 5 minutes of liquid injection oil

cooling) are given in the following table:

LIQUID LINE SIZE and RECEIVER VOLUME

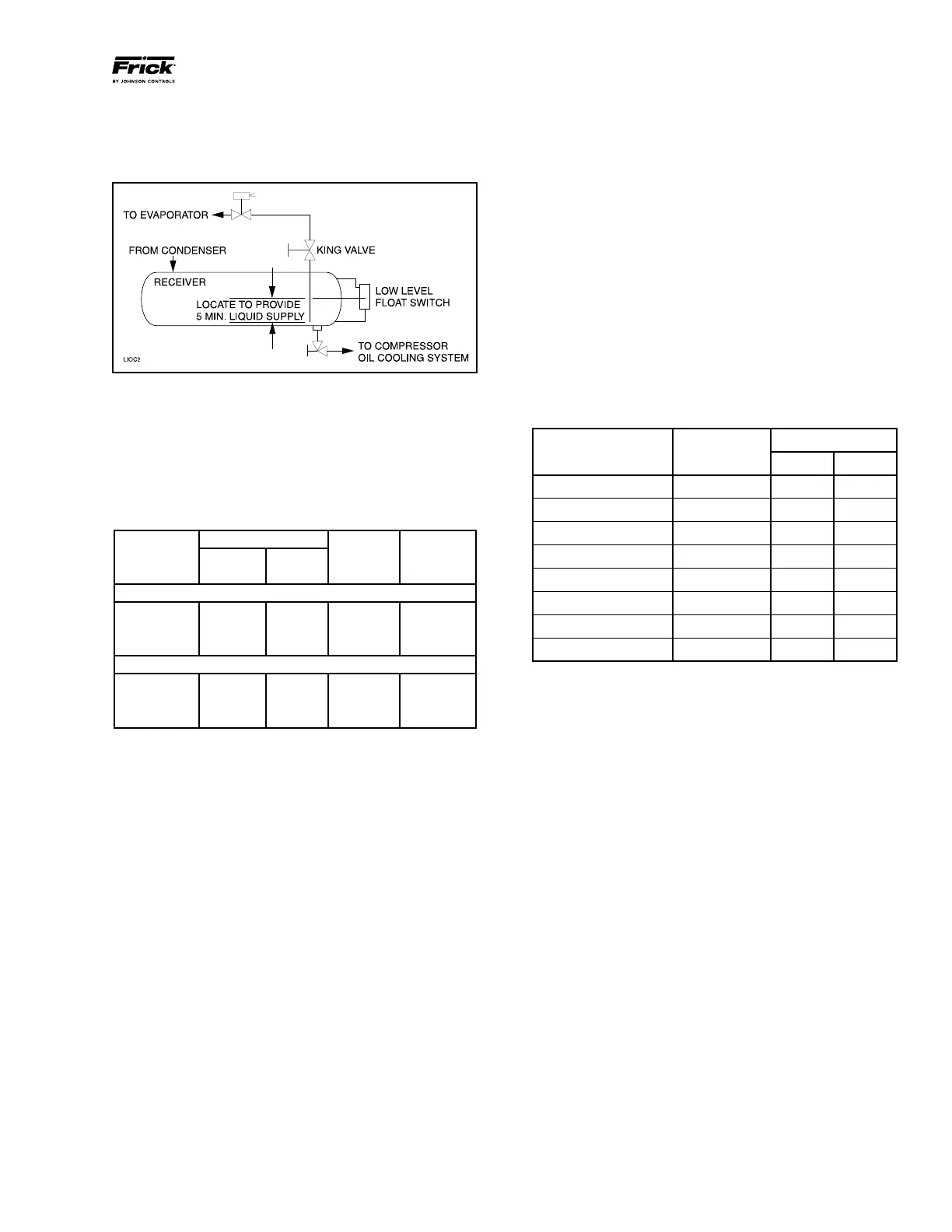

The level‑control method utilizes a float level control on the

receiver to close a solenoid valve feeding the evaporator

when the liquid falls below that amount necessary for 5

minutes of liquid injection oil cooling. See Figure 10.

Figure 10

In some applications, the plate and shell oil cooler may be

subjected to severe water conditions, including high tem‑

perature and/or hard water conditions. This causes accel‑

erated scaling rates which will penalize the performance of

the heat exchanger. A chemical cleaning process will extend

the life of the Plate and Shell heat exchanger. It is important

to establish regular cleaning schedules.

Cleaning: A 3% solution of Phosphoric or Oxalic Acid is

recommended. Other cleaning solutions can be obtained from

your local distributor, but they must be suitable for stainless

steel. The oil cooler may be cleaned in place by back flushing

with recommended solution for approximately 30 minutes.

After back flushing, rinse the heat exchanger with fresh water

to remove any remaining cleaning solution.

NOTE: The water-regulating valve shipped with the unit

will be sized to the specific flow for the unit.

OIL COOLER DATA TABLE

RWB II TYPICAL

CONNECTION

MODEL COOLER INLET OUTLET

60 ‑ 134 High Stage 116 Plates 3" 3"

100 ‑ 270 Booster 66 Plates 2" 2"

177/222 High Stage 190 Plates 3" 3"

270 High Stage 288 Plates 3" 4"

316/399 Booster 56 Plates 3" 3"

316/399 High Stage 136 Plates 4" 5"

480 Booster 72 Plates 3" 3"

480 High Stage 188 Plates 4" 5"

LINE SIZE* POUND LIQUID

RWB II

SCH 80 OD

PER VOLUME

MODEL ** PIPE TUBING 5 MIN. CU FT

R-717 HIGH STAGE*

100‑134 3/4 – 80 2.0

177‑270 1 – 140 4.0

316‑480 1¼ – 250 7.0

R-717 BOOSTER*

100‑134 1/2 – 20 0.5

177‑270 3/4 – 30 1.0

316‑480 1 – 40 1.5

Loading...

Loading...