RWB II ROTARY SCREW COMPRESSOR UNITS

INSTALLATION

070.200-IOM (DEC 11)

Page 15

ECONOMIZER LOAD BALANCING

The most energy efficient manner to operate an economizer

system, when using multiple compressors on a common

economizer vessel, is to take as much of the flash gas as

possible to the compressors that are fully loaded. This can

be done in at least two ways.

1. Use the economizer output from the microprocessor to

turn off a solenoid, or to actuate the electric shutoff option

on a back‑pressure regulator, based on percent of slide valve

travel. This will direct all the flash vapor to the other loaded

compressors.

2. A dual‑setpoint back‑pressure regulator valve can be used

in each of the individual economizer vapor lines. When a com‑

pressor is running near full load, the BPR valve will operate

on the desired setpoint, or basically wide open, to minimize

pressure drop in the line. When one compressor unloads

below the slide valve position where the economizer output

on the microprocessor turns on, the dual‑setpoint feature of

the regulator can be actuated by this output to control the

pressure, on the vessel side of the regulator, to be a few psi

higher. Consequently, the flash gas will be sent to the loaded

compressors first, until they can’t handle all the vapor and

the pressure in the vessel starts to rise. Then, some of the

vapor will go to the unloaded compressor to help maintain

the vessel at the desired pressure. An example of a back‑

pressure regulator with electric shutoff and the dual‑setpoint

feature is an R/S A4ADS.

ELECTRICAL

NOTE: Before proceeding with electrical installation,

read the instructions in the section “Proper Installation

of Elec tronic Equip ment in an Industrial Environment”.

RWB II units are supplied with a QUANTUM control system.

Care must be taken that the controls are not exposed to

physical damage during handling, storage, and installa tion.

The single‑box control door must be kept tightly closed to

prevent moisture and foreign mat ter from entry.

NOTE: All customer connections are made in the single-

box control mounted on the oil separator. This is the

ONLY electrical enclosure and it should be kept tightly

closed whenever work is not being done in it.

VOLTAGE PROTECTION

Johnson Controls‑Frick does not advise nor support the use

of UPS power systems in front of the Quantum panel. With

a UPS power system providing shutdown protection for the

Quantum, the panel may not see the loss of the 3‑phase volt‑

age on the motor because the UPS could prevent the motor

starter contactor from dropping out. With the starter contactor

still energized, the compressor auxiliary will continue to feed

an “Okay” signal to the panel. This will allow the motor to be

subjected to a fault condition on the 3‑phase bus. Some fault

scenarios are:

1. The 3‑phase bus has power “on” and “off” in a continuous

cyclic manner which may cause the motor to overheat

due to repeated excessive in‑rush currents.

2. Motor cycling may damage the coupling or cause other

mechanical damage due to the repeated high torque

motor “bumps”.

3. Prolonged low voltage may cause the motor to stall and

overheat before the motor contactor is manually turned

off.

Under normal conditions, the loss of 3‑phase power will

shut the Quantum panel down, and it will restart upon power

return. If the panel was in:

• Auto – Compressor motor will return to running as

programmed.

• Remote – The external controller would reinitialize the

panel and proceed to run as required.

• Manual – The compressor will have to be restarted

manually after the 3‑phase bus fault has been cleared.

If the local power distribution system is unstable or prone

to problems, there are other recommendations to satisfy

these problems. If power spikes or low or high line voltages

are the problem, then Johnson Controls‑Frick

®

recommends

the use of a Sola

®

constant voltage (CV) transformer with

a line suppression feature. If a phase loss occurs, then you

will typically get a high motor amp shutdown. If problems

continue to exist, then an examination of the plant’s power

factor may be in order.

Unless careful design failure analysis is considered in the

implementation of power systems, the alternative solutions

provide a safer and less expensive implementation. In either

case, only one Sola

®

may be used per compressor. Each

compressor needs to be individually isolated from each other

through a dedicated control transformer. Sharing a common

control power source is an invitation for ground loops and

the subsequent unexplainable problems.

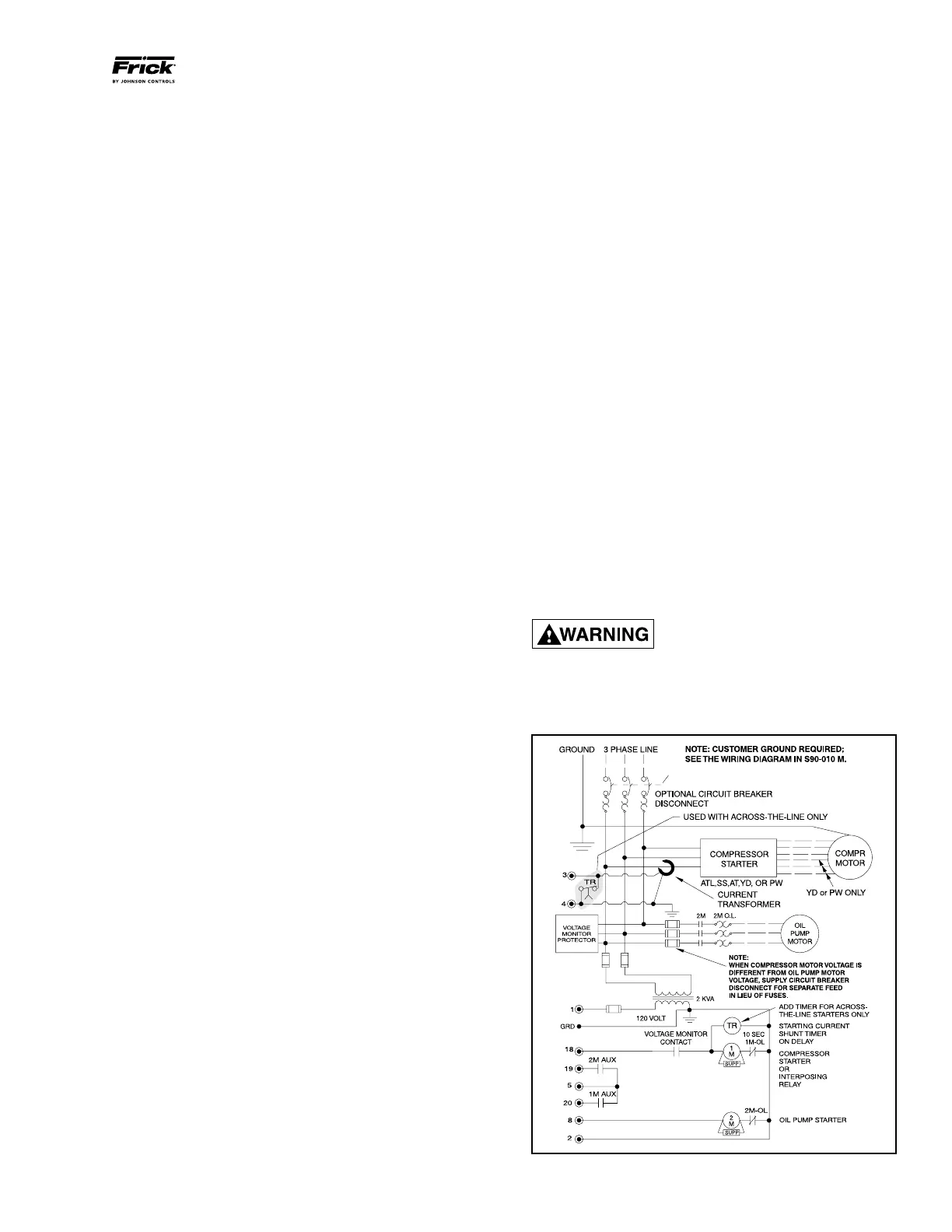

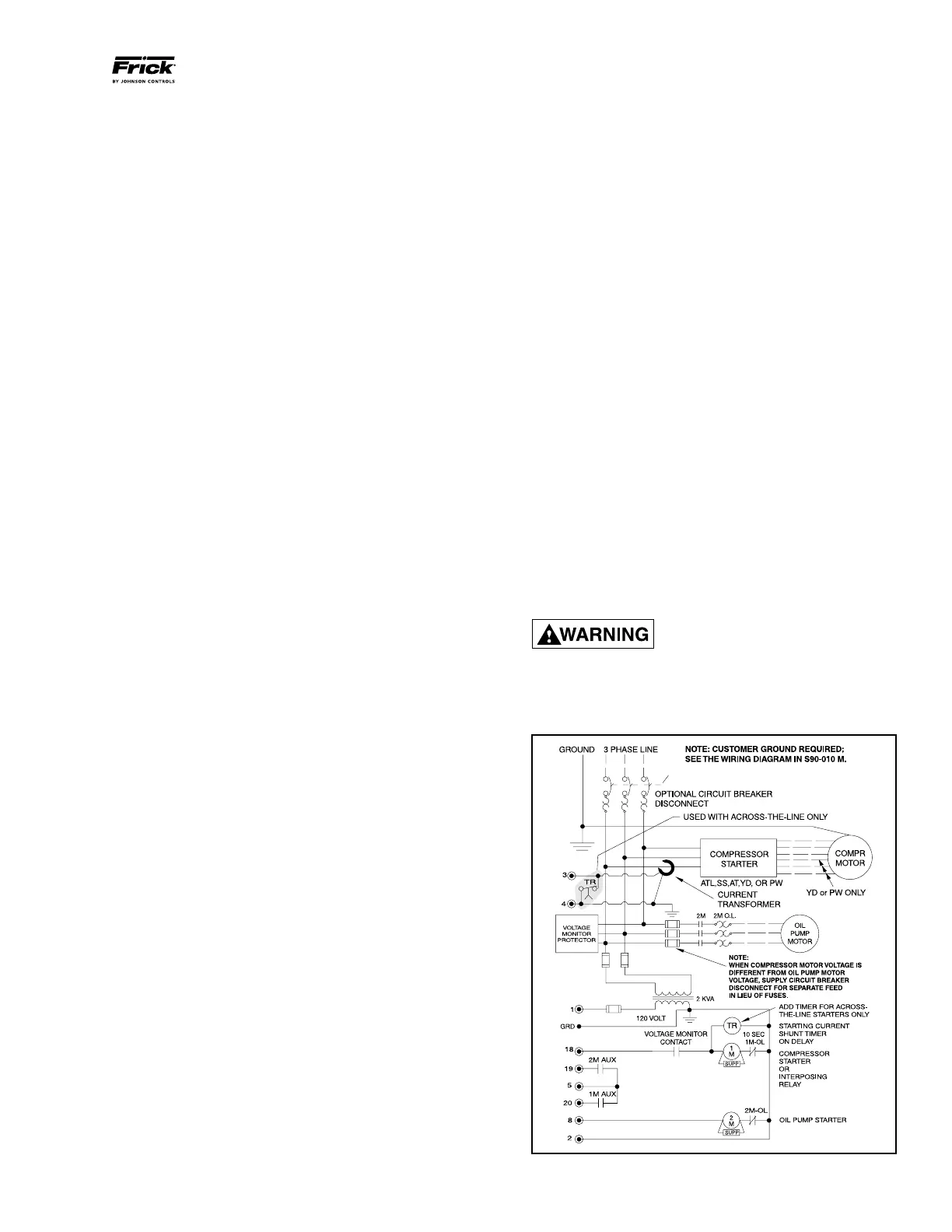

MOTOR STARTER PACKAGE

SBC Board damage may occur

without timer relay installed in con-

trol panel as shown in Starter Wir-

ing Diagram, Figure 15. All Frick motor starter packages

have the timer relay as standard.

STARTER WIRING DIAGRAM

Figure 15

Loading...

Loading...