RWB II ROTARY SCREW COMPRESSOR UNITS

MAINTENANCE

070.200-IOM (DEC 11)

Page 34

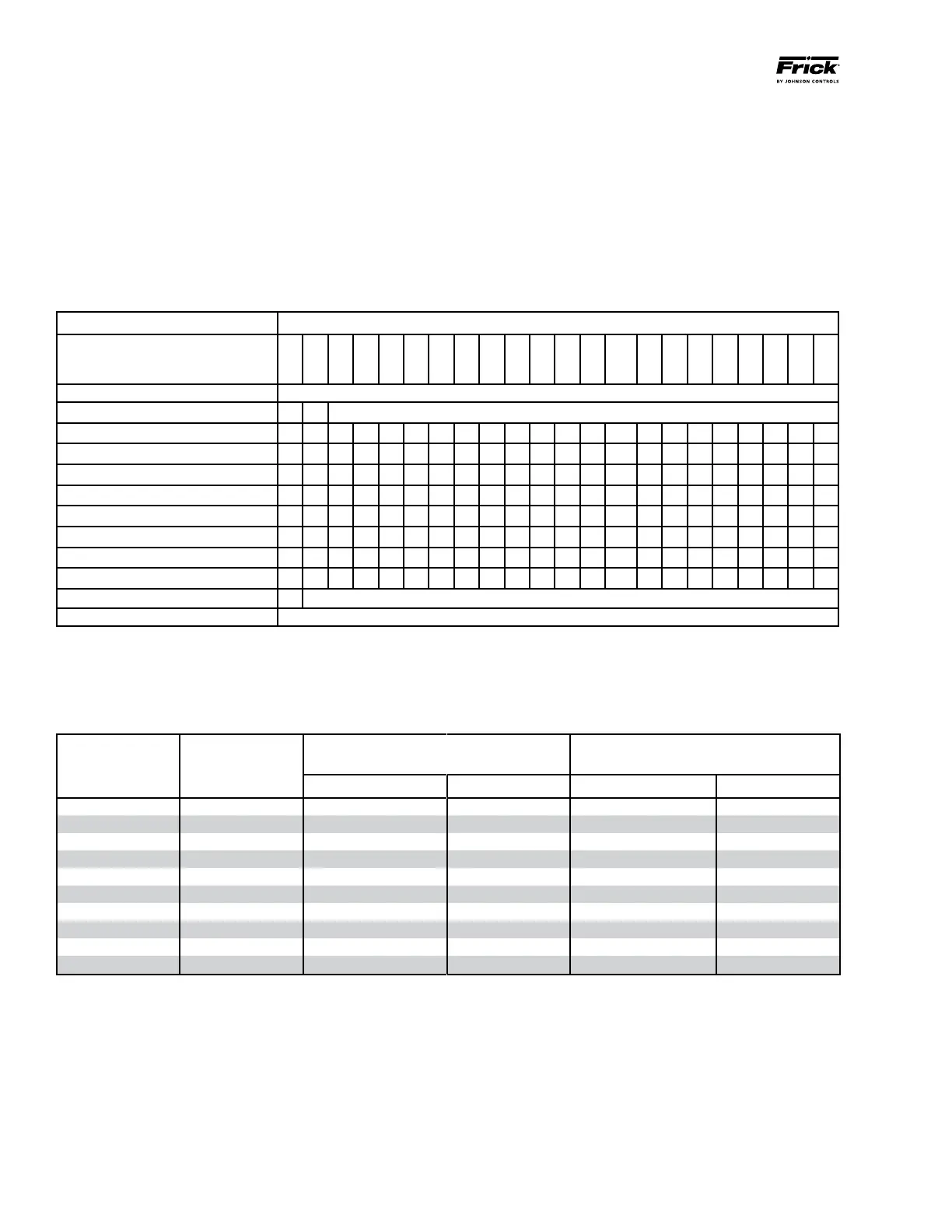

MAINTENANCE SCHEDULE

This schedule should be followed to ensure trouble‑free operation of the compressor unit.

OPERATING LOG

The use of an operating log, as included in this manual, permits thorough analysis of the operation of a refrigeration system by

those responsible for its maintenance and servicing. Continual recording of gauge pressures, temperatures, and other pertinent

information, enables the observer and serviceman to be constantly familiar with the operation of the system and to recognize

immediately any deviations from normal operating conditions. It is recommended that readings be taken at least every four hours.

See Table of Contents for "OPERATING LOG SHEET".

FREQUENCY OR HOURS OF OPERATION (MAXIMUM)

MAINTENANCE

200

1000

5000

8000

10,000

15,000

20,000

25,000

30,000

35,000

40,000

45,000

50,000

55,000

60,000

65,000

70,000

75,000

80,000

85,000

90,000

95,000

Change Oil As Directed By Oil Analysis

Oil Analysis

n

Every 6 Months

Replace Filters

n

n

n

n

n

n

n

n

n

n

n

Clean Oil Strainers

n

n

n

n

n

n

n

n

n

n

n

Clean Liquid Strainers

n

n

n

n

n

n

n

n

n

n

n

Replace Coalescers

n

n

n

Check and Clean Suction Strainer

n n n

n

n

n

n

n

n

n

n

n

Check Alignment

n

n

n

n

n

n

n

n

n

n

n

Check Coupling (a)

n

n

n

n

n

n

n

n

n

n

n

Suction & Disch Flange Bolts (b)

n n n n n n n n n n n n n n n n n n n n n n

Vibration Analysis (c)

n

Every 6 Months, More Frequently If Levels Increase

Replace Shaft Seal When Leak Rate Exceeds 7 ‑ 8 Drops Per Minute

a. Check bolts, shim packs, center inserts, keys, and all bolt torques.

b. Verify tightness of bolts on suction and discharge flanges. See table below for torque requirements.

c. Vibration measurement must be carried out continuously to obtain optimum preventative control on bearings. If not continuously controlled,

then every 6 months, more frequently if levels increase.

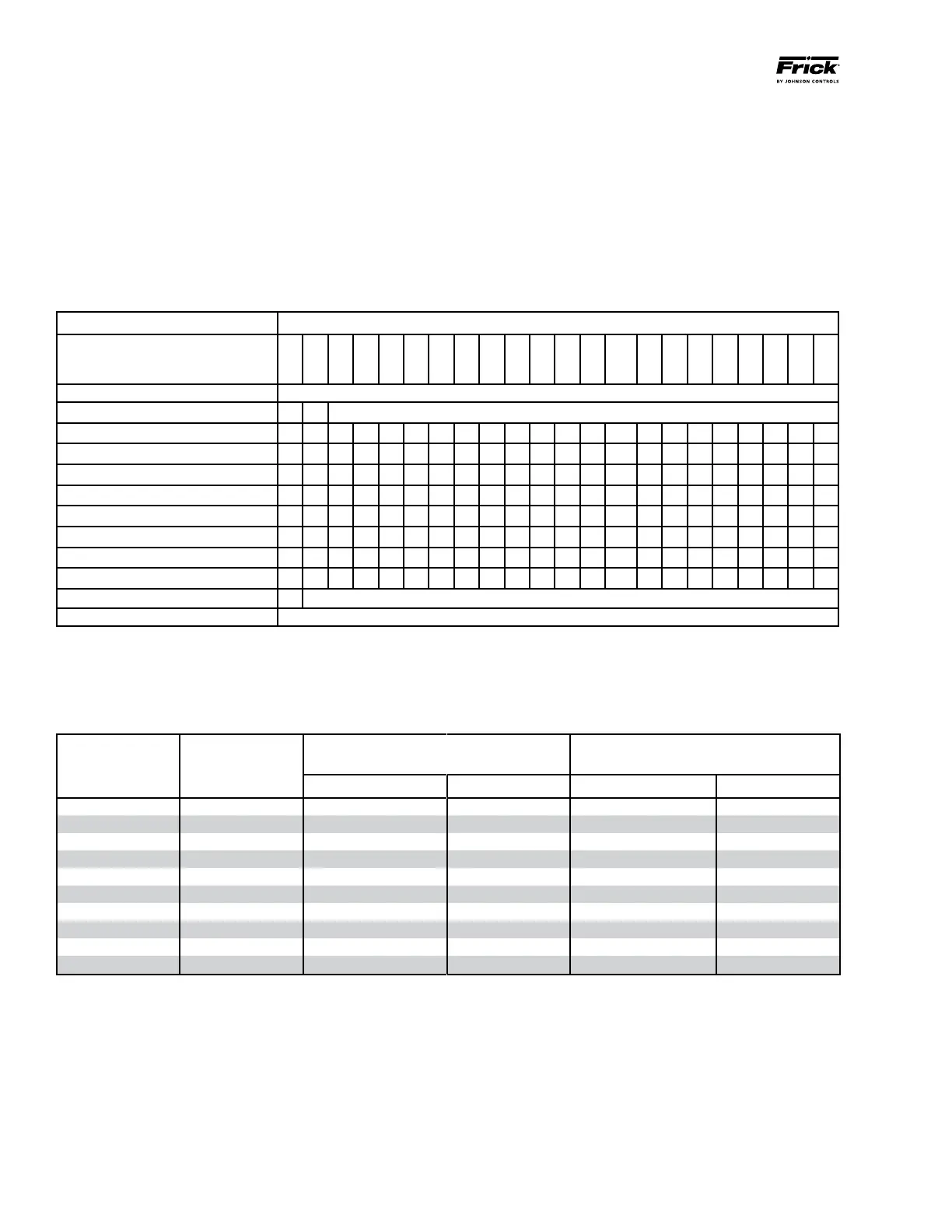

NOTE:

1. The bolt torque requirements for the compressor flange to separator flange are based on:

a. Gaskets: Garlock

®

Blue‑Gard

®

3300

b. Bolts: class 8.8 or stronger hex head bolts, lightly oiled and clean

TDSH Flange Bolt Torque

RWBII MODEL

Compressor

Model

Discharge Flange to

Separator Flange Suction Flange

Bolt Size (in.) Torque (ft-lb) Bolt Size (in.) Torque (ft-lb)

60 163S M20 X 2.5 100 M16 X 2.0 120

76 163L M20 X 2.5 100 M16 X 2.0 120

100 193S M20 X 2.5 140 M20 X 2.5 180

134 193L M20 X 2.5 140 M20 X 2.5 160

177 233S M20 X 2.5 160 M20 X 2.5 160

222 233L M20 X 2.5 160 M20 X 2.5 200

270 233XL M20 X 2.5 160 M22 X 2.5 220

316 283S M22 X 2.5 230 M22 X 2.5 220

399 283L M22 X 2.5 230 M22 X 2.5 220

480 283SX M22 X 2.5 230 M24 X 3.0 220

Loading...

Loading...