RWB II ROTARY SCREW COMPRESSOR UNITS

INSTALLATION

070.200-IOM (DEC 11)

Page 10

HOT ALIGNMENT OF COMPRESSOR/MOTOR

Hot alignments can only be made after the unit has operated

for several hours and all components are at operating tem‑

peratures.

Shut down the unit and quickly affix dial indicator to coupling

motor hub, then take readings of both the face and rim of the

compressor hub. If these readings are within tolerance, record

reading, attach coupling guard and restart unit. However, if

the reading is not within limits, compare the hot reading with

the cold alignment and adjust for this difference; i.e. if the

rim at 0° and 180° readings indicates that the motor rises

.005" between its hot and cold state, .005" of shims should

be removed from under the motor.

After the initial hot alignment adjustment is made, restart unit

and bring to operating temperature. Shut down and recheck

hot alignment. Repeat procedure unit hot alignment is within

specified tolerance.

INSTALL COUPLING GUARD BE-

FORE OPERATING COMPRESSOR.

OIL PUMP COUPLING

Compressor units with direct motor/pump coupled pumps

need no pump/motor coupling alignment since this is main‑

tained by the close‑coupled arrangement.

HOLDING CHARGE AND STORAGE

Each RWB II compressor unit is pressure and leak tested at

the Frick factory and then thoroughly evacuated and charged

with dry nitrogen to ensure the integrity of the unit during

shipping and short term storage prior to installation.

NOTE: Care must be taken when entering the unit to

ensure that the nitrogen charge is safely released.

Holding charge shipping gauges on

separator and external oil cooler

are rated for 30 PSIG and are for

checking the shipping charge only. They must be re-

moved before pressure testing the system and before

charging the system with refrigerant. Failure to remove

these gauges may result in catastrophic failure of the

gauge and uncontrolled release of refrigerant resulting

in serious injury or death.

All units must be kept in a clean, dry location to prevent

corrosion damage. Reasonable consideration must be

given to proper care for the solid‑state components of the

microprocessor.

Unit which will be stored for more than two months must have

the nitrogen charge checked periodically.

COMPRESSOR UNIT OIL

DO NOT MIX OILS of different

brands, manufacturers, or types.

Mixing of oils may cause excessive

oil foaming, nuisance oil level cutouts, oil pressure loss,

gas or oil leakage and catastrophic compressor failure.

NOTE: The oil charge shipped with the unit is the best

suited lubricant for the conditions specified at the time

of purchase. If there is any doubt due to the refrigerant,

operating pressures, or temperatures, refer to Frick Pub.

160-802 SPC for guidance.

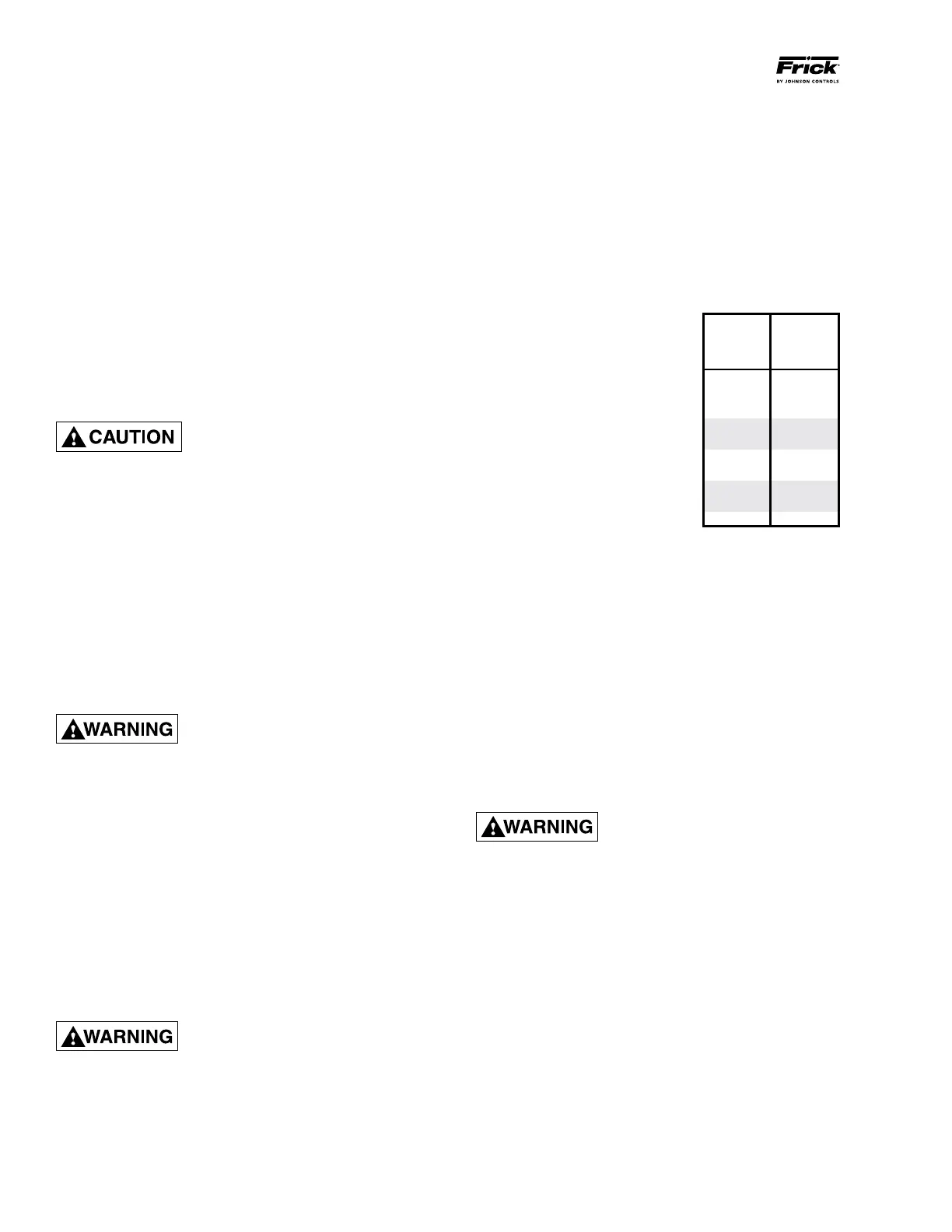

OIL CHARGE

The normal charging level is midway in the top sight glass

located midway along the oil separator shell. Normal oper-

ating level is midway between the top sight glass and

bottom sight glass. The table gives the approximate oil

charge quantity.

* Includes total in oil separator and piping. Additional oil sup‑

plied for oil cooler.

Add oil by attaching the end of a

suitable‑pressure‑type hose to the

oil charging valve, located on the

top of the oil separator at the com‑

pressor end. Using a pressure‑type

pump and the recommended Frick

oil, open the charging valve and

pump oil into the separator. NOTE:

Fill slowly because oil will fill up

in the separator faster than it

shows in the sight glass.

Oil distillers and similar equipment

which act to trap oil must be filled

prior to unit operation to normal design outlet levels. The

same pump used to charge the unit may be used for filling

these auxiliary oil reservoirs.

NOTE: The sight glass located in the coalescing end

of the separator near the discharge connection should

remain empty.

OIL HEATER(S)

Standard units are equipped with two or three 500 watt oil

heaters, providing sufficient heat to maintain the oil tempera‑

ture for most indoor applications during shutdown cycles

to permit safe start‑up. Should additional heating capacity

be required because of low ambient temperature, contact

Frick. The heaters are energized only when the unit is not

in operation.

DO NOT ENERGIZE THE HEATERS

when there is no oil in the unit, the

heat ers will burn out. The oil heat-

ers will be energized whenever 120 volt control power

is applied to the unit and the com pressor is not run ning,

unless the 16 amp circuit breaker in the micro enclosure

is turned off.

60 35

76 35

100 65

134 65

177 110

222 110

270 140

316 140

399 140

480 170

BASIC*

CHARGE

(gal.)

RWB II

MODEL

NO.

Loading...

Loading...