RWB II ROTARY SCREW COMPRESSOR UNITS

INSTALLATION

070.200-IOM (DEC 11)

Page 7

All rotating power transmission equipment is potentially dangerous. Ensure that the couplings are

properly guarded prior to turning on the power. Coupling guards are provided with the equipment

and must be in place and secured properly while the equipment is in operation.

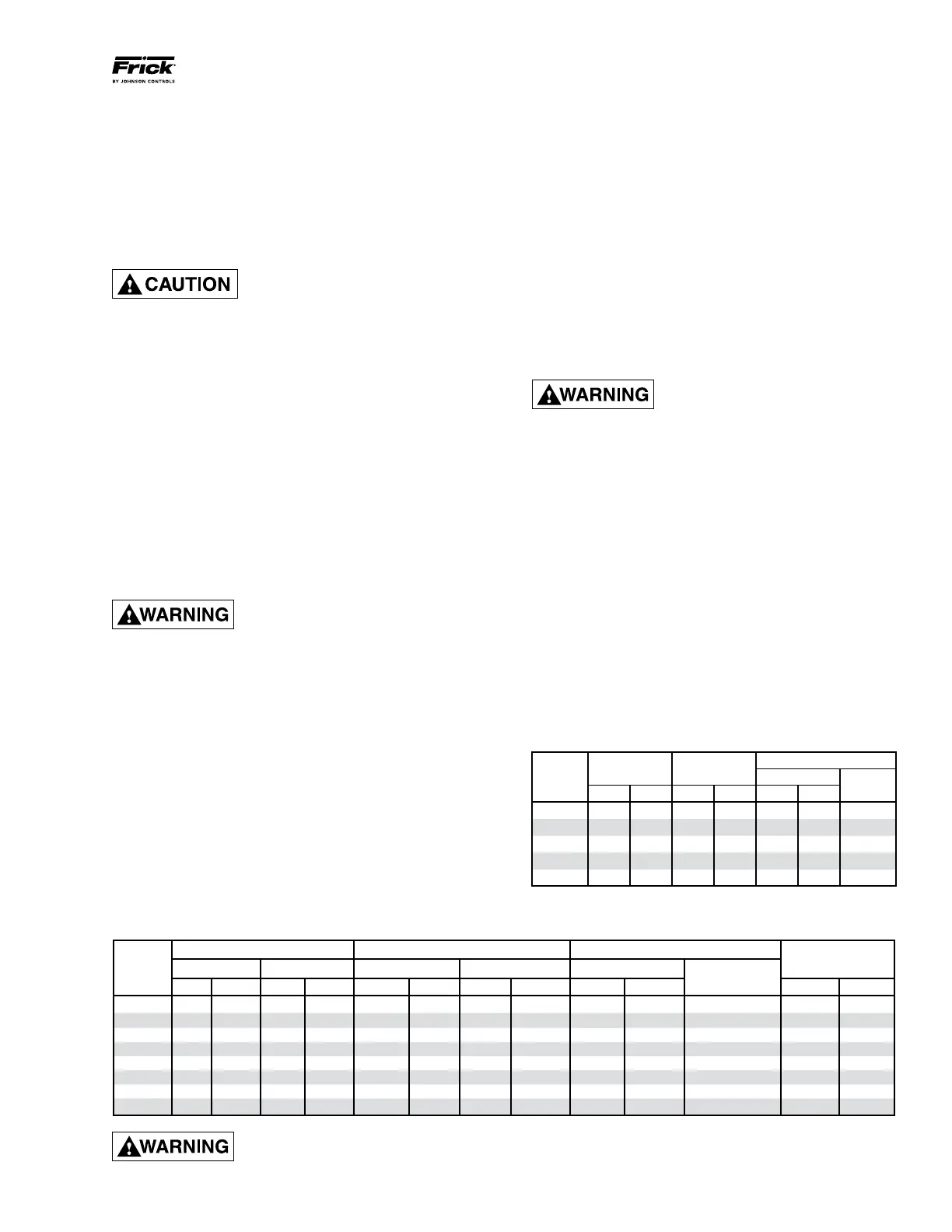

SERIES 52 COUPLING DATA TABLE

3. Adjust the distance between hub faces as specified in the

DBZ‑B Data Table by sliding the hubs. Key and secure hubs

to the shafts by tightening setscrews.

4. Reinstall the eight previously removed bolts and locknuts.

Alternately tighten each locknut as you would the lug nuts on

an automobile. NOTE: ALWAYS TURN THE NUT. NEVER

TURN THE BOLT.

5. Torque the locknuts to the value shown in the DBZ‑B Data

Table for the size coupling being installed.

Lubricated and/or plated bolts and

locknuts develop higher bolt ten-

sion with less tightening than those

that are dry and not plated. Torques for lubricated and/or

plated bolts and locknuts will generally fall in the lower range;

while those that are dry or as received from the factory fall

into the upper range. Torque readings should be ob served

while locknut is being turned.

6. Proceed to coupling alignment.

SERIES 52 COUPLING – The Thomas Series 52 coupling is

also used on applications above 600 HP. It has two drive hubs,

a center spool, and disc packs which are bolted between the

center spool and each drive hub. A center spool and two flex‑

ible steel disc packs serve as the drive element. These three

parts, situated between the motor and compressor hubs,

prevent axial end float between the motor and compressor

shafts. End float tends to occur with sleeve bearing motors.

The magnetic center of the sleeve bearing motors must be

determined and maintained by securing the coupling hub to

the motor shaft with the shaft properly located.

Injury may occur if loose clothing,

etc. becomes entangled on the

spinning motor shaft.

If the motor is coupled to the compressor using a fixed‑end‑

play coupling such as the Series 52 coupling and the motor

is not properly centered, the additional thrust loads will be

transmitted to the compressor bearings. This additional thrust

could result in premature bearing failure. Install as follows:

1. Before proceeding with the alignment process found

on pages 7 and 8 of this manual, disassemble the Series

52 coupling noting the arrangement of bolts, washers,

and nuts as THEY MUST BE REPLACED IN THE SAME

ORDER. Mark the adjoining bolt holes of each part, the two

hubs, the two disc packs, and the center spool, so they are

put back together in the same position.

2. Mount the coupling hubs on their respective shafts. The

hub is bored for an interference fit on the shaft. Heating of

the coupling hub may be necessary for assembly. DO NOT

SPOT HEAT THE HUB as it may cause distortion. Heat in

water, oil, or use a SOFT open flame and quickly position

on the shaft.

3. Adjust the distance between hub faces, as specified in the

Series 52 Coupling Data Table, by sliding the hubs. Key and

secure the hubs to the shafts by tightening the set screws.

4. Reassemble the coupling with the disc packs and the

center spool. Ensure that they are reassembled exactly as

they were disassembled.

WOODS BP SERIES COUPLING – is also used on appli‑

cations above 600 HP. It utilizes a center spool and two flex‑

ible steel disc packs as the drive element. These three parts,

situated between the motor and compressor hubs, prevent

axial end float between the motor and compressor shafts.

End float tends to occur with sleeve bearing motors.

Injury may occur if loose clothing,

etc. becomes entangled on the

spinning motor shaft.

If the motor is coupled to the compressor using a fixed‑end‑

play coupling and the motor is not properly centered, the

additional thrust loads will be transmitted to the compressor

bearings. This additional thrust could result in premature

bearing failure. Install the BP Series coupling using the fol‑

lowing instructions:

1. Before proceeding with the alignment process in the fol‑

lowing section, disassemble the BP Series coupling noting

the arrangement of bolts, washers, and nuts as THEY

MUST BE REPLACED IN THE SAME ORDER. Mark the

adjoining bolt holes of each part, the two hubs, the two disc

packs, and the center spool, so they are put back together

in the same position.

2. Install the motor and compressor coupling hubs on their

respective shafts with the keys. Ensure that the hubs slide,

so that when the shim packs are installed, no axial stresses

are transferred to the shim packs because the coupling hub

is stuck.

COUP-

HUB FACE MAX TOTAL INDICATOR READING SETSCREW

CLAMP BOLT

LING

SPACING +/- ANGULAR PARALLEL TORQUE (LUBE) TORQUE (LUBE)

SIZE in. mm in. mm in. mm in. mm ft-lb Nm

SIZE

ft-lb Nm

225 5 127 1/32 0.914 0.004 0.102 0.004 0.102 7.5 10.5 1/4‑20 UNRF 25 33.9

262 5 127 1/32 0.914 0.004 0.102 0.004 0.102 22 30.6 3/8‑24 UNRF 30 40.7

312 5½ 139.7 3/64 1.295 0.004 0.102 0.004 0.102 37 51.5 7/16‑20 UNRF 40 54.2

350 6 152.4 3/64 1.295 0.004 0.102 0.004 0.102 55 76.5 1/2‑20 UNRF 95 128.8

375 7 177.8 1/16 1.574 0.004 0.102 0.004 0.102 55 76.5 1/2‑20 UNRF 130 176.3

425 7 177.8 1/16 1.574 0.004 0.102 0.004 0.102 96 133.6 5/8‑18 UNRF 175 237.3

450 8 203.2 1/16 1.574 0.004 0.102 0.004 0.102 96 133.6 5/8‑18 UNRF 200 271.2

500 9 228.6 5/64 2.083 0.004 0.102 0.004 0.102 250 348 7/8‑14 UNRF 260 352.5

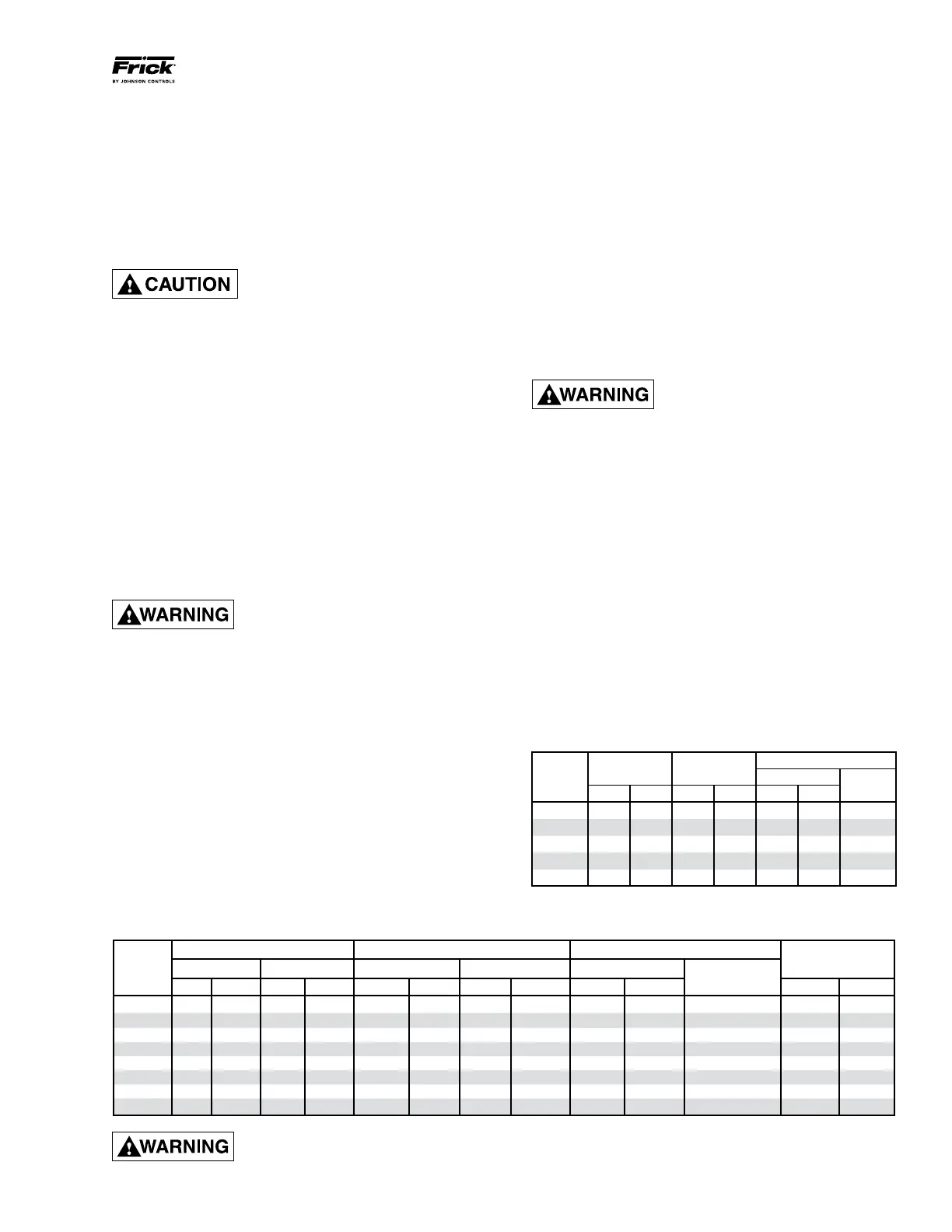

BP SERIES COUPLING DATA TABLE

BP HUB FACE * DISC PACK CLAMP BOLT

SERIES SPACING BOLT TORQ. TORQ. DRY SIZE

SIZE in. mm ft-lb Nm ft-lb Nm UNF

BP48 4.88 124 40 54 41 56

3

/

8

‑24

BP53 5.88 150 60 81 65 88

7

/

16

‑20

BP58 6.00 152 120 163 100 136

1

/

2

‑20

BP58 6.69 170 120 163 100 136

1

/

2

‑20

BP63 7.00 179 120 163 100 136

1

/

2

‑20

* Max total indicator reading .003 in. or .076 mm for all sizes.

Loading...

Loading...