RWB II ROTARY SCREW COMPRESSOR UNITS

MAINTENANCE

070.200-IOM (DEC 11)

Page 30

oil. Check for roughness by turning outer race by hand and

replace bearings if they have roughness.

Be sure shaft is free from nicks, burrs and foreign particles

that might damage mechanical seal. Scratches on shaft in

seal area will provide leakage paths under mechanical seal.

Use fine emery cloth to remove scratches or sharp edges.

DEMAND PUMP ASSEMBLY

Assembly Notes On Standard Mechanical Seal (Synthetic

Rubber Bellows Type)

NOTE: Read carefully before reassembling pump

The seal used in this pump is simple to install and good

performance will result if care is taken during installation.

The principle of mechanical seal is contact between the

rotary and stationary members. These parts are lapped to

a high finish and their sealing effectiveness depends on

complete contact.

Prior to installing rotary portion of mechanical seal, prepare

and organize rotor shaft, head and idler assemblies and ap‑

propriate gaskets for quick assembly

Once rotary portion of mechanical seal is installed on rotor

shaft, it is necessary to assemble parts as quickly as pos‑

sible to ensure that the seal does not stick to shaft in wrong

axial position. The seal will stick to the shaft after several

minutes setting time.

Never touch sealing faces with anything except clean hands

or clean cloth. Minute particles can scratch the seal faces

and cause leakage.

1. Coat idler pin with refrigeration oil and place idler and

bushing on idler pin in head. If replacing a carbon‑graphite

bushing, refer to "Installation of Carbon Graphite Bushings".

2. Clean rotor hub and casing seal housing bore. Make sure

both are free from dirt and grit. Coat outer diameter of seal

seat and inner diameter of seal housing bore with refrigera‑

tion oil.

3. Start seal seat in seal housing bore. If force is necessary,

protect seal face with a clean cardboard disc and gently tap it

in place with a piece of wood. Be sure seal seat is completely

seated in the bore.

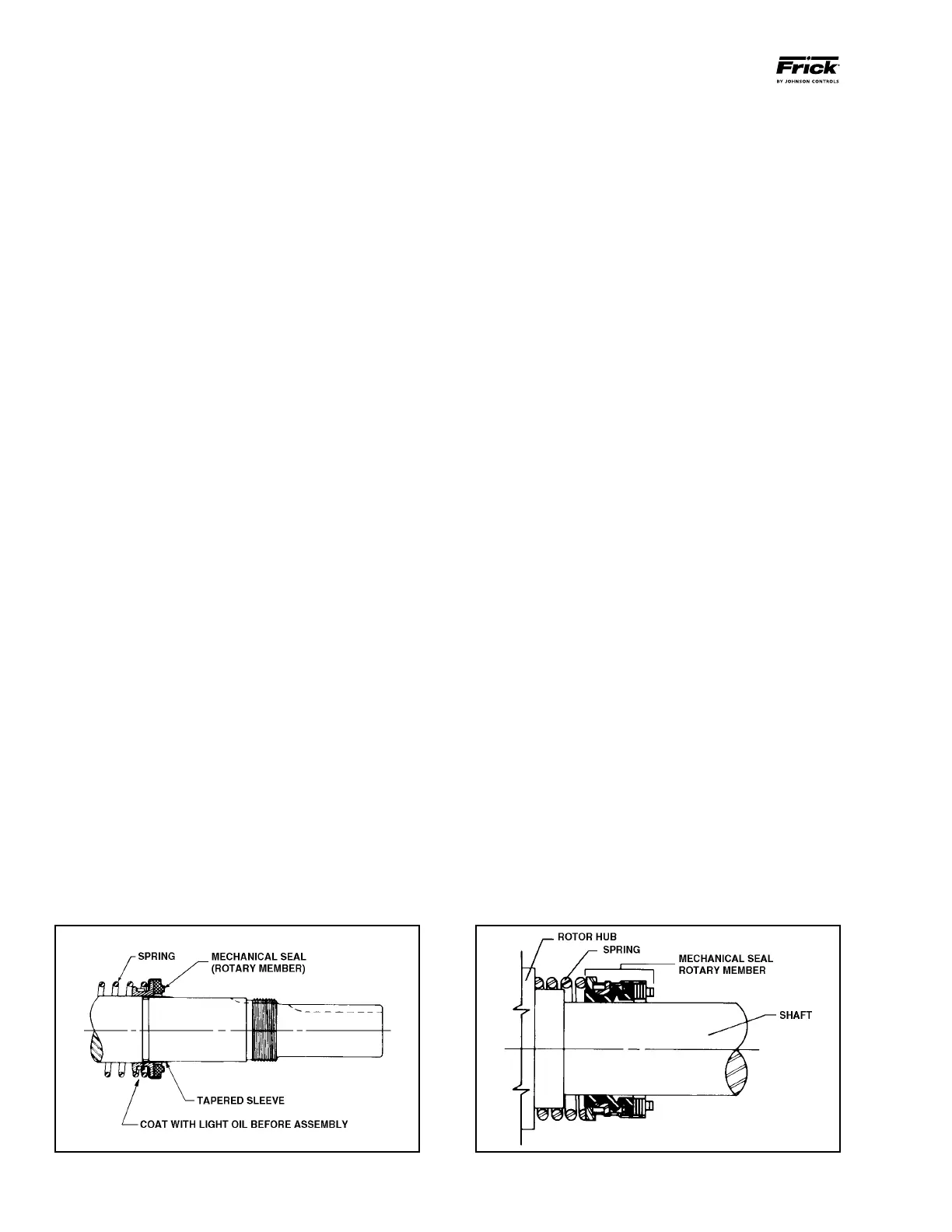

4. Place tapered installation sleeve on shaft. Refer to Figure

28. Sleeve is furnished with GG, AS, AK, and AL replace‑

ment mechanical seals. Coat rotor shaft, tapered installation

Figure 28

sleeve, and inner diameter of mechanical seal rotary mem ber

with a generous amount of refrigeration oil. Petrolatum may

be used but grease is not recommended.

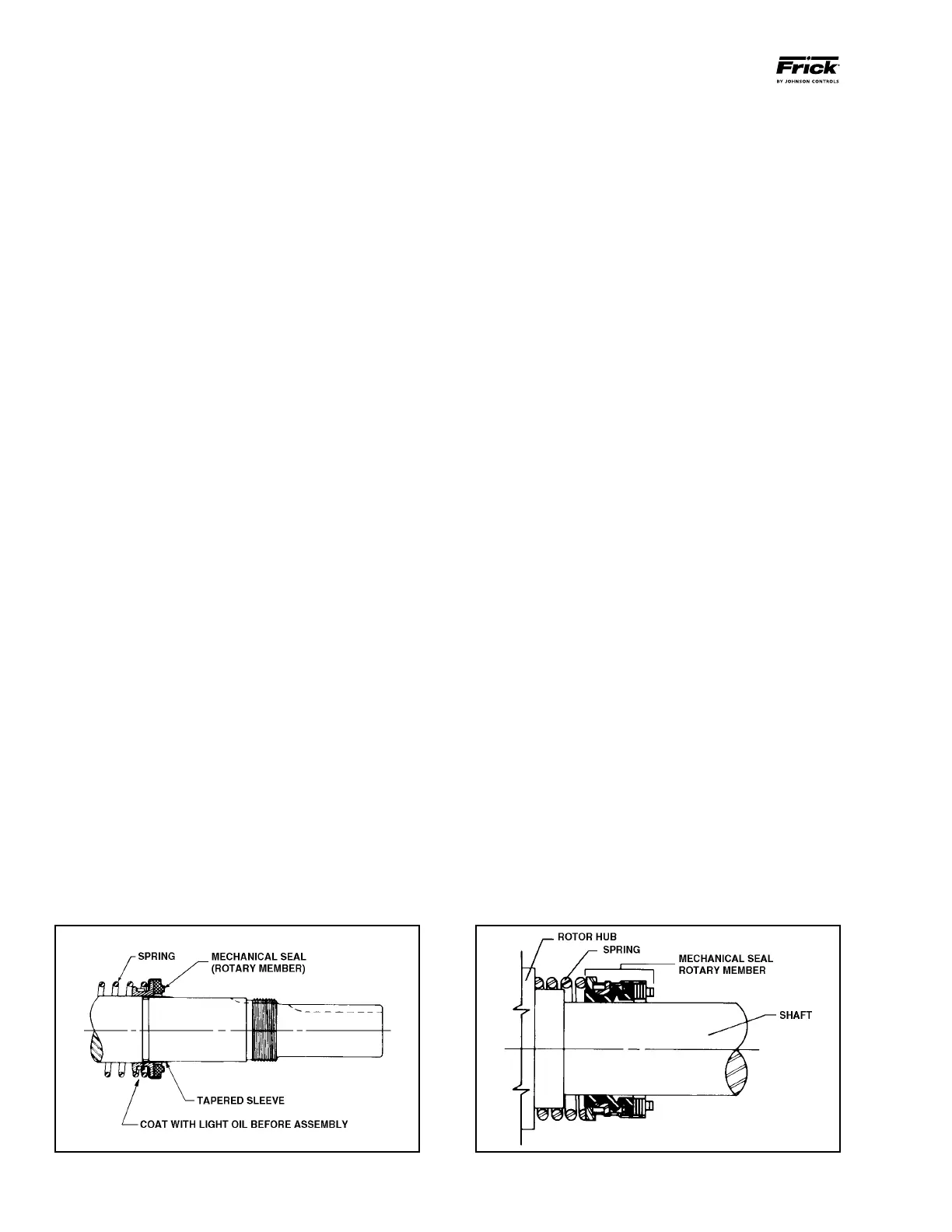

5. Place seal spring on shaft against rotor hub. Refer to

Figure 28.

6. Slide rotary member, with lapped contact surface facing

away from spring, over installation sleeve on shaft until just

con tacting the spring. Do not compress spring. Remove

installa tion sleeve.

7. Coat rotor shaft with refrigeration oil. Install shaft slowly

pushing until the ends of rotor teeth are just below the face

of the casing.

8. Leave the rotor in this position. Withdrawal of rotor and

shaft may displace the carbon seal rotating face and result

in damage to the seal.

9. Place O‑ring gasket on head and install head and idler

assembly on pump. Pump head and casing were marked

before disassembly to ensure proper reassembly. If not, be

sure idler pin, which is offset in pump head, is positioned up

and equal distance between port connections to allow for

proper flow of liquid through pump.

10. Tighten head capscrews evenly

11. Pack inner ball bearing with multipurpose grease,

NLGI #2.

GG, HJ, HL: Install bearing in casing with sealed side towards

head end of pump. Drive the bearing into the bore. Tap the

inner race with a brass bar and lead hammer to position

bearing. Install inner snap ring.

AS, AK, AL: Install bearing retainer washer over the shaft

before installing ball bearing. Install ball bear ing in casing with

sealed side towards head end of pump. Drive the bearing

into the bore. Tap the inner race with a brass bar and lead

hammer to position bearing.

12. GG, HJ, HL: Install shaft snap ring in groove in the shaft.

See Figure 25.

AS, AK, AL: Install bearing spacer over shaft and against

single row ball bearing. See Figure 26.

13. Pack lubrication chamber between inner ball bearing

and double‑row ball bearing in the thrust‑bearing assembly

approximately one‑half full of multipurpose grease, NLGI #2.

The thrust‑bearing assembly will take the remaining space.

See Figure 25 and 26.

Figure 27

Loading...

Loading...