RWB II ROTARY SCREW COMPRESSOR UNITS

PROPER INSTALLATION OF ELECTRONIC EQUIPMENT

070.200-IOM (DEC 11)

Page 49

GROUNDING

Grounding is the most important factor for successful opera‑

tion and is typically the most overlooked. The NEC states that

control equipment may be grounded by using the rigid conduit

as a conductor. This worked for the earlier relay systems, but

it is in no way acceptable for electronic control equipment.

Conduit is made of steel and is a poor conductor relative to an

insulated stranded copper wire. Electronic equipment reacts

to very small currents and must have a proper ground in order

to operate properly; therefore, stranded copper grounds are

required for proper operation.

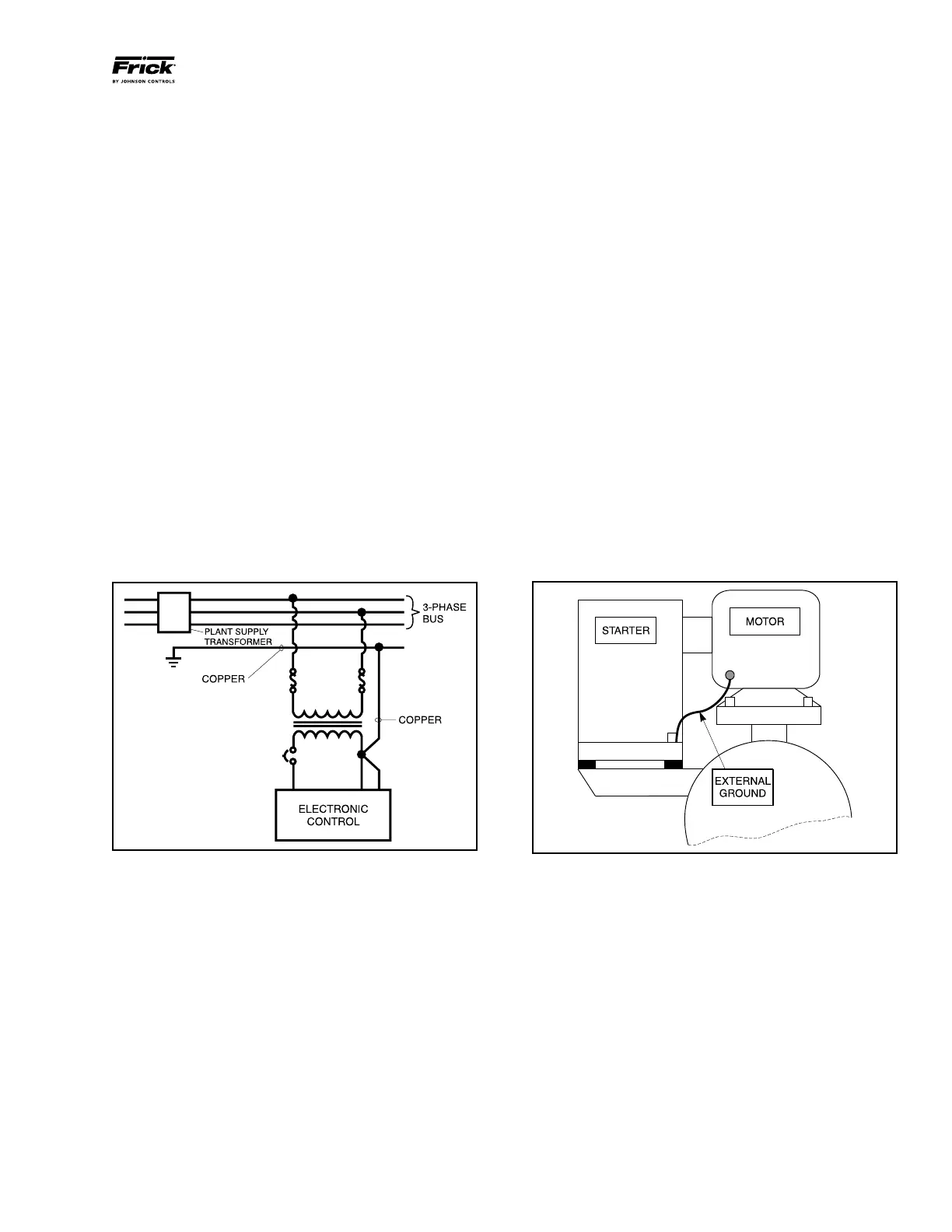

For proper operation, the control power ground circuit must

be a single continuous circuit of the proper sized insulated

stranded conductor, from the electronic control panel to the

plant supply transformer (Figure 41). Driving a ground stake

at the electronic control may also cause additional problems

since other equipment in the plant on the same circuits may

ground themselves to the ground stake causing large ground

flow at the electronic control panel. Also, running multiple

ground conductors into the electronic control panel from

various locations can create multiple potentials resulting in

ground loop currents. A single ground wire (10 AWG or 8

AWG) from the electronic control panel, that is bonded to

the control power neutral at the secondary side of the control

power transformer in the starter and then to the 3‑phase

ground point, will yield the best results.

Figure 41

NOTE: Structural grounding can also result in multiple

ground potentials and is also a relatively poor conductor.

Therefore, this is not an acceptable method for proper

operation of electronic equipment.

There must be a ground for the three‑phase power wiring.

This must be sized in accordance to the NEC and any local

codes relative to the highest rated circuit overload protec‑

tion provided in the circuit. The manufacturer may require a

larger ground conductor than what is required by the NEC

for proper steering of EMI from sensitive circuits. This con‑

ductor must also be insulated to avoid inadvertent contact at

multiple points to ground, which could create Ground Loops.

In many installations that are having electronic control prob‑

lems, this essential wire is usually missing, is not insulated,

or improperly sized.

NEC size ratings are for safety purposes and not necessarily

for adequate relaying of noise (EMI) to earth ground to avoid

possible interference with sensitive equipment. Therefore siz‑

ing this conductor 1 – 2 sizes larger than required by code

will provide better transfer of this noise.

Johnson Controls‑Frick

®

requires that the ground conductor

meet the following:

• Stranded Copper

• Insulated

• One size larger than NEC requirements for conventional

starters

• Two sizes larger than NEC requirements for VFD

starters

• Conduit must be grounded at each end

• This circuit must be complete from the motor to the starter

continuing in a seamless manner back to the plant supply

transformer (power source).

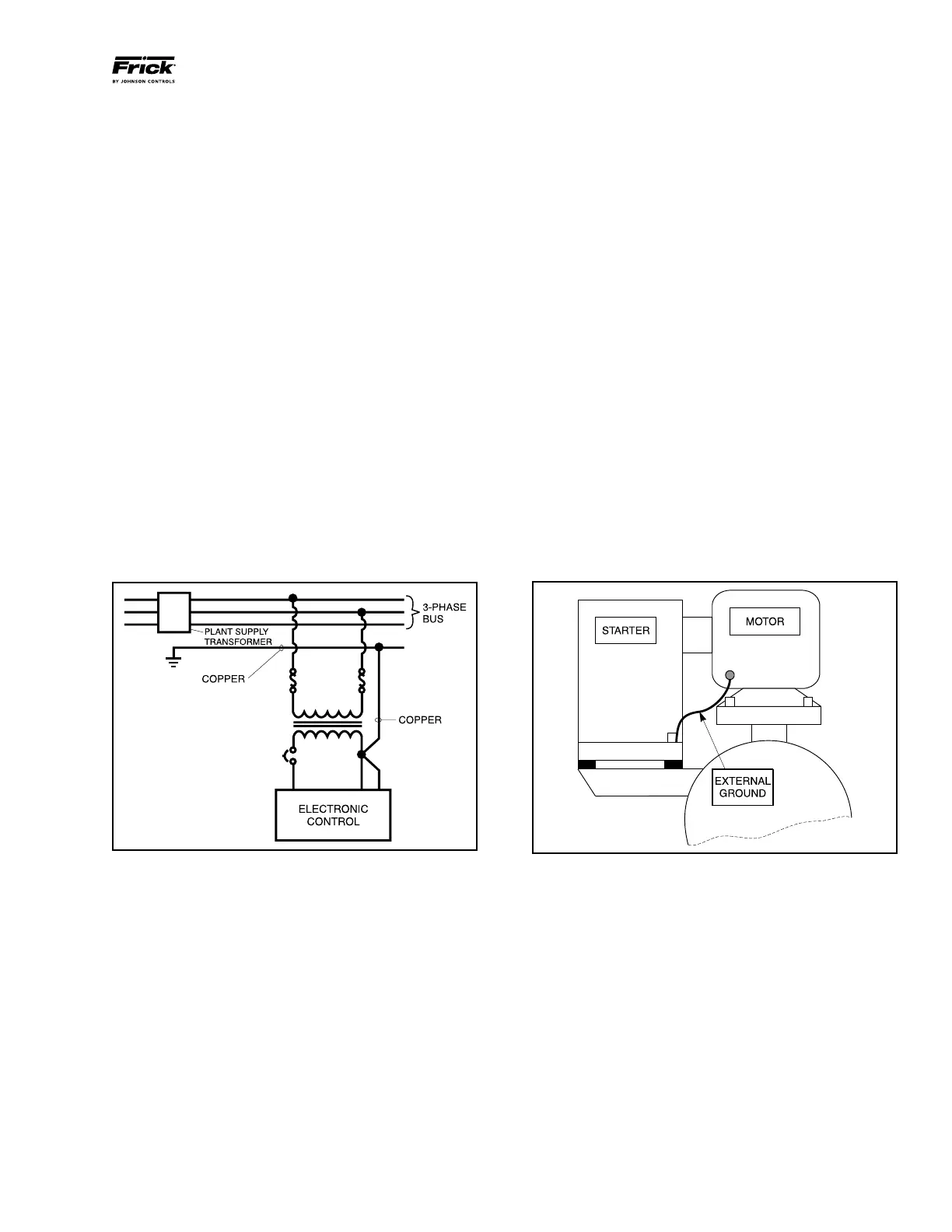

For Direct Coupled, Package Mounted Starters, the ground

between the motor and the starter may need to be made

externally (Figure 42). The connection on the starter end

must be on the starter side of the vibration isolators. Be

certain the connection is metal to metal. Paint may need

to be removed to ensure a proper conductive circuit. The

use of counter‑sunk star washers at the point of connec‑

tion at each end will maximize metal to metal contact.

Figure 42

VFD APPLICATIONS

The primary ground conductor that accompanies the three‑

phase supply must be stranded copper, insulated and two

sizes larger than the minimum required by the NEC or

any other applicable codes. This is necessary due to the

increased generation of EMI which is a characteristic of a

VFD output to the motor when compared to a conventional

starter.

For VFD applications, isolation of the control power, analog

devices, and communications ground from the 3‑phase

ground within the starter and the electronic control panel may

be necessary. This is due to the higher noise (RFI/EMI) levels

generated between the VFD output and the motor, relative

to a conventional starter. If these grounds are left coupled

Loading...

Loading...