Engineering manual - SAB 193-233-283 S A-frame (including ATEX)

008831 en 2020.10

105/168

Installation instructions

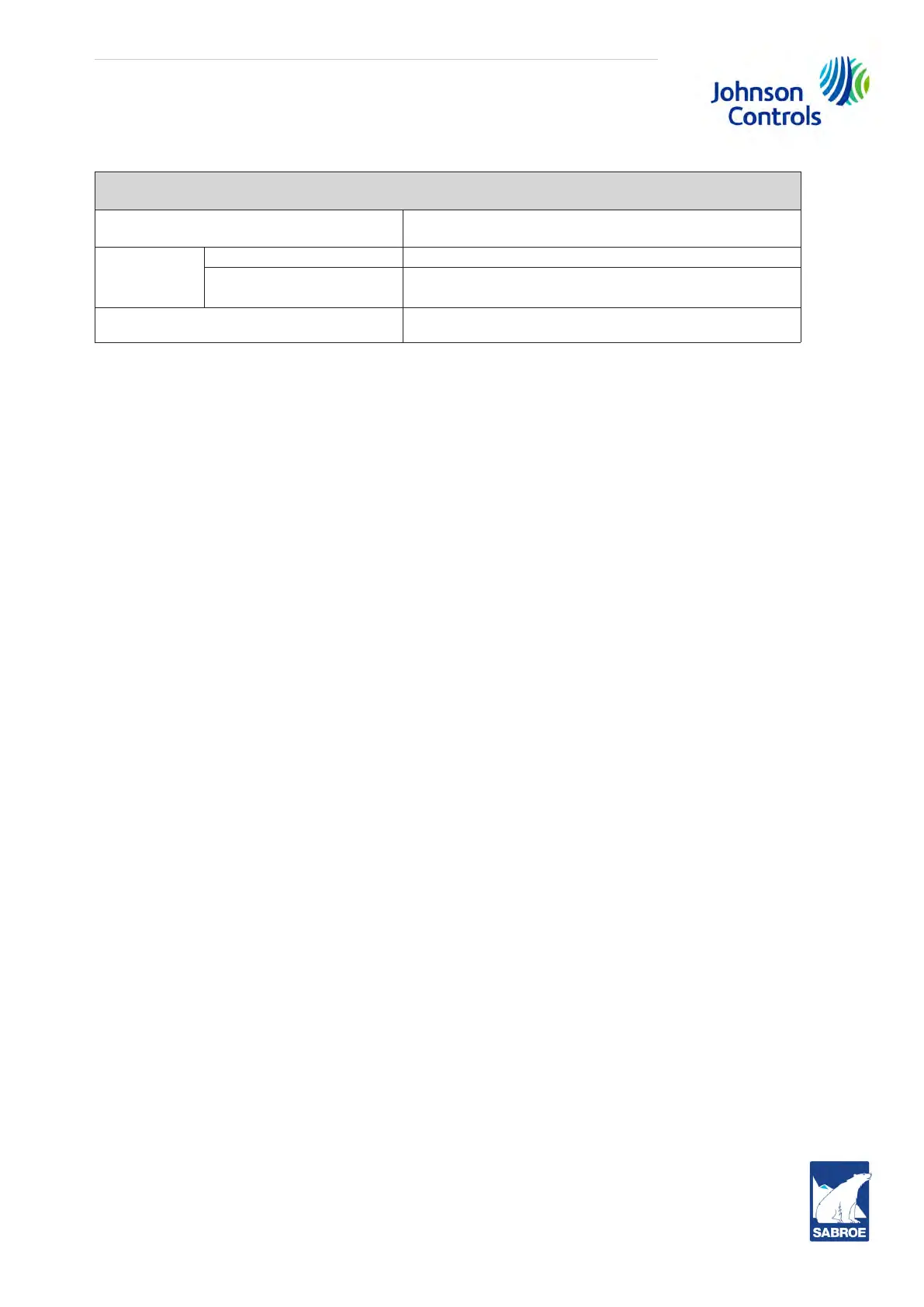

Max. variation at 180°C rotation

mm

Pos. 1

horizontal

0–0.10

Pos. 1

vertical

Roller + slide bearings 0.05–0.15 above shaft with slide bearings

Roller + roller or

slide + slide bearings

0–0.10

Pos. 2 0–0.10

Table 26

Achieving correct centre height

• Turn the coupling so that the alignment gauge is faced vertically down.

• Guide the measuring pin (pos. 1) towards the coupling flange using a 1.0 mm feeler

gauge, and fix the pin.

• Remove the feeler gauge.

• Rotate the coupling 180° and measure the increase in distance "z" from one millimetre us-

ing feeler gauges.

• Lift the motor by placing shims of a thickness equal to half the value of "z" under all four

feet.

• After securing the motor, repeat the measurement and compare the result to the values in

Table 26, pos. 1 vertical.

Achieving parallel shafts in vertical plane

The motor is now positioned at the correct height. What remains is to push and turn the motor at

the level on which it is already lined up.

• Turn the coupling so that the alignment gauge faces out to one side horizontally.

• Guide both measuring pins towards the coupling with a 1.0 mm feeler gauge in between.

• Turn the coupling 180° and use feeler gauges to measure deviations from one millimetre

at both pins.

• Move and turn the motor and repeat this measurement.

• Align the motor in accordance with pos. 1 horizontal and pos. 2 in Table 26.

• Check that the distance C is still correct according to the coupling type.

Remember that the motor must be firmly secured during any measurement.

Loading...

Loading...