3-16

DIP switch 2: Setting as per specification

1 ON: Selection of TR6/TR5 model: ON for TR6, OFF for TR5

2 OFF: Selection of D/S model: ON for D (TR6D, TR5D), OFF for S (TR6S, TR5S)

3 2: Selection of language: ON for English, OFF for Japanese

4 2: Direction of transfer: ON for left to right, OFF for right to left

5 OFF: CMPNT35.0 (used for TR5)

6 ON: WDT

7 OFF: Disabling limit signals (used for debugging)

8 OFF: Enabling/disabling mounter cover open

DIP switch 3: Optional setting

1 2: Slow 2 mode: ON/OFF

2 2: BOX for run-out components: ON/OFF

3 ON: Function preventing wrong tray insertion

4 2: Inspection transfer: ON/OFF

5 2: Automatic width adjustment of transfer section: ON/OFF

6 2: Supporting EX size PWB: ON/OFF

7 ON: Flash memory starting mode

8 OFF: Two lights of the signal tower (used for TR6D)

DIP switch 4: Revision of pattern functions

1 3: P_REV_0

2 3: P_REV_1

3 3: P_REV_2

4 3: P_REV_3

5 3: F_REV_0

6 3: F_REV_1

7 3: F_REV_2

8 3: F_REV_3

DIP switch 5: Spare

1 2: RFID

2 1: Spare

3 4: Specifies the shuttle pad when BGA is used.

4 4: Specifies the shuttle pad when BGA is used.

5 1: Spare

6 1: Spare

7 1: Spare

8 ON: Supporting KE-3020/3020R/3010/3020V/3020VR connection: ON/OFF

DIP switch 6: Spare

1 1: Spare

2 1: Spare

3 1: Spare

4 1: Spare

5 1: Spare

6 1: Spare

7 1: Spare

8 1: Spare

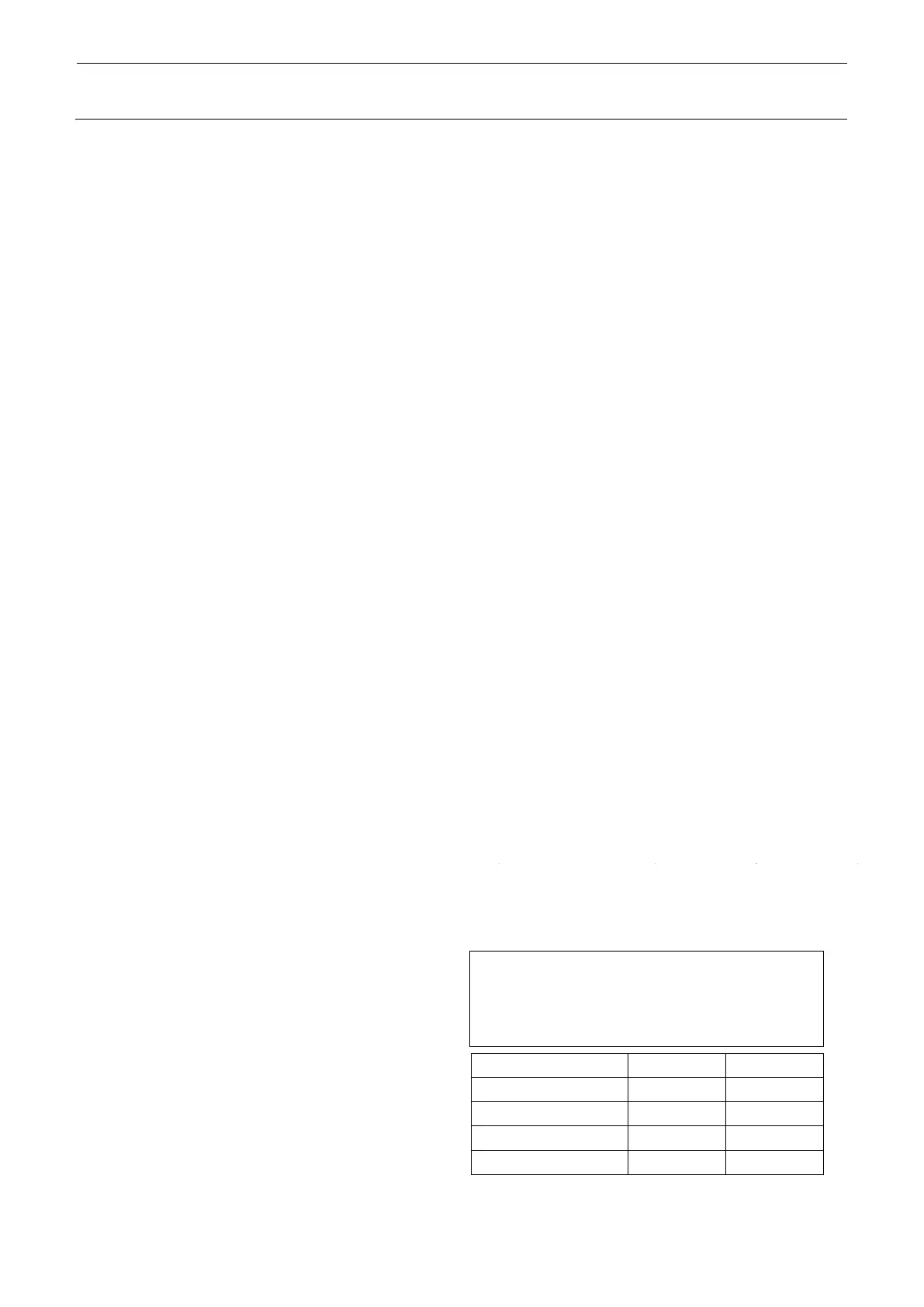

4. If the shuttle BGA is used, you can

specify a desired shuttle pad by

selecting the appropriate dip switch

combination from among the followings.

1. The setting is made according to the software specifications,

such as special order.

Make the same setting as that on the previous PCB.

2. Make the setting after checking the machine specifications.

3. The setting has been made at shipment of the PCB. So, the

setting is not needed.

Loading...

Loading...