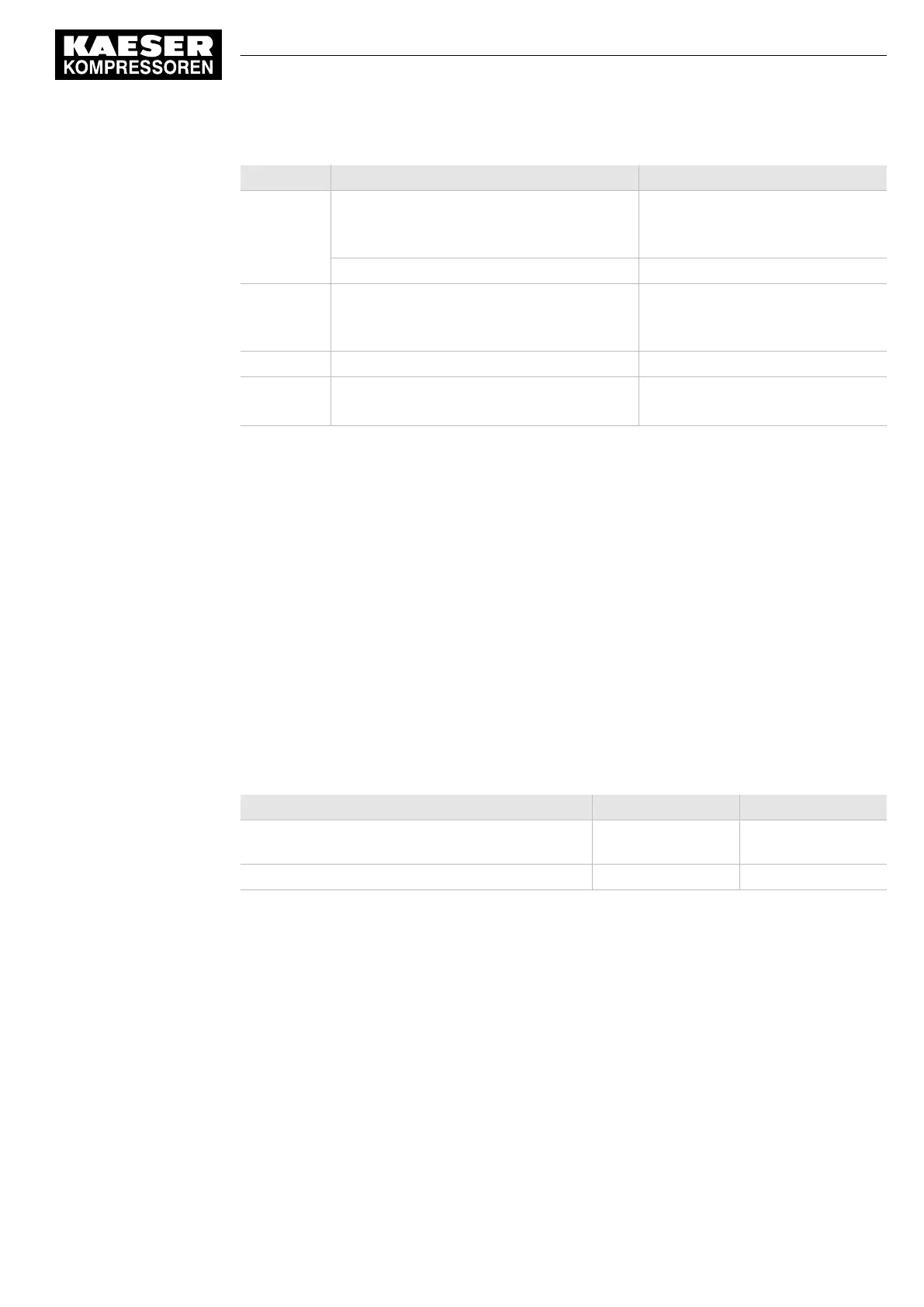

Activity Danger area Authorised personnel

Transport Within a 3 m radius of the machine. Installation personnel for transport

preparation.

No personnel during transport.

Beneath the lifted machine. No personnel!

Installation Within the machine.

Within 1 m radius of the machine and its sup‐

ply cables.

Installation personnel

Operation Within a 1 m radius of the machine. Operating personnel

Maintenance Within the machine.

Within a 1 m radius of the machine.

Maintenance personnel

Tab. 41 Danger Areas

3.6 Safety devices

Various safety devices ensure safe working with the machine.

➤ Do not change, bypass or disable safety devices.

➤ Regularly check safety devices for their correct function.

➤ Do not remove or obliterate labels and notices.

➤ Ensure that labels and notices are clearly legible.

Further information More information on safety devices is contained in chapter 4, section 4.2.1.

3.7 Service life of safety functions

Pursuant to ISO 13849-1:2008, Category and Performance Level (PL) of the machine's safety

functions have been analysed and assessed:

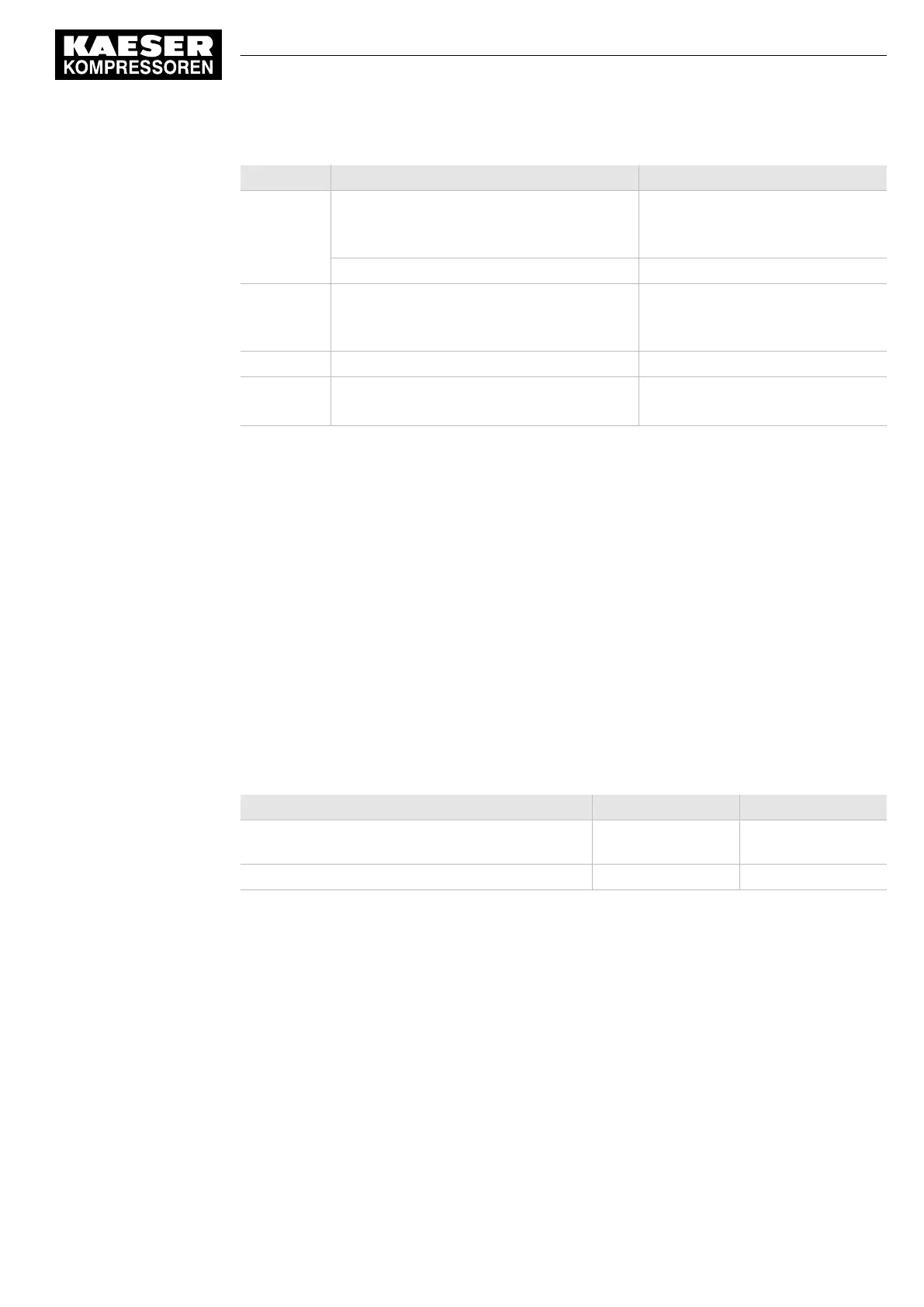

Safety function Category Performance Level

Safety shut-down due to excessive airend discharge

temperature

2 c

EMERGENCY STOP device 1 c

Tab. 42 Category and Performance Level

The safety-relevant components of the safety functions are designed for a working life of 20 years.

The working life starts with the commissioning, and is not extended by times during which the ma‐

chine was not in use.

The following components are affected:

■ Resistance thermometer (Pt100 sensor for measuring the compression discharge temperature)

■ EMERGENCY STOP control device

■ Mains contactor

1. The components of the safety functions must be replaced by KAESER SERVICE after a work‐

ing life of 20 years.

2. Have the KAESER SERVICE check the reliability of the safety functions.

3 Safety and Responsibility

3.6 Safety devices

901824 12 E

Operating Manual Screw Compressor

ASK

25

Loading...

Loading...