6.6 Options

6.6.1 Option H1

Anchoring the machine

➤ Use appropriate fixing bolts to anchor the machine.

Further information Details of the fixing holes are contained in the dimensional drawing in chapter 13.3.

6.6.2 Option W2/W3

Connecting the heat recovery system

➤ Take the electrochemical series into consideration and choose suitable materials for con‐

nections.

➤ Keep the effect of pressure surges on the heat exchanger as low as possible.

➤ Install an expansion tank to act as a damper if pressure surges cannot be avoided.

➤ Install appropriate regulating devices if the heat transfer medium is to be kept constant.

➤ Avoid very low inlet temperatures of the heat transfer medium as it can cause condensa‐

tion. If required, contactKAESER for suitable insulation measures.

WARNING

Cooling oil in the heat-receiving medium!

Oil may contaminate the medium if a leak occurs.

➤ Do not use the heat-receiving medium as drinking water.

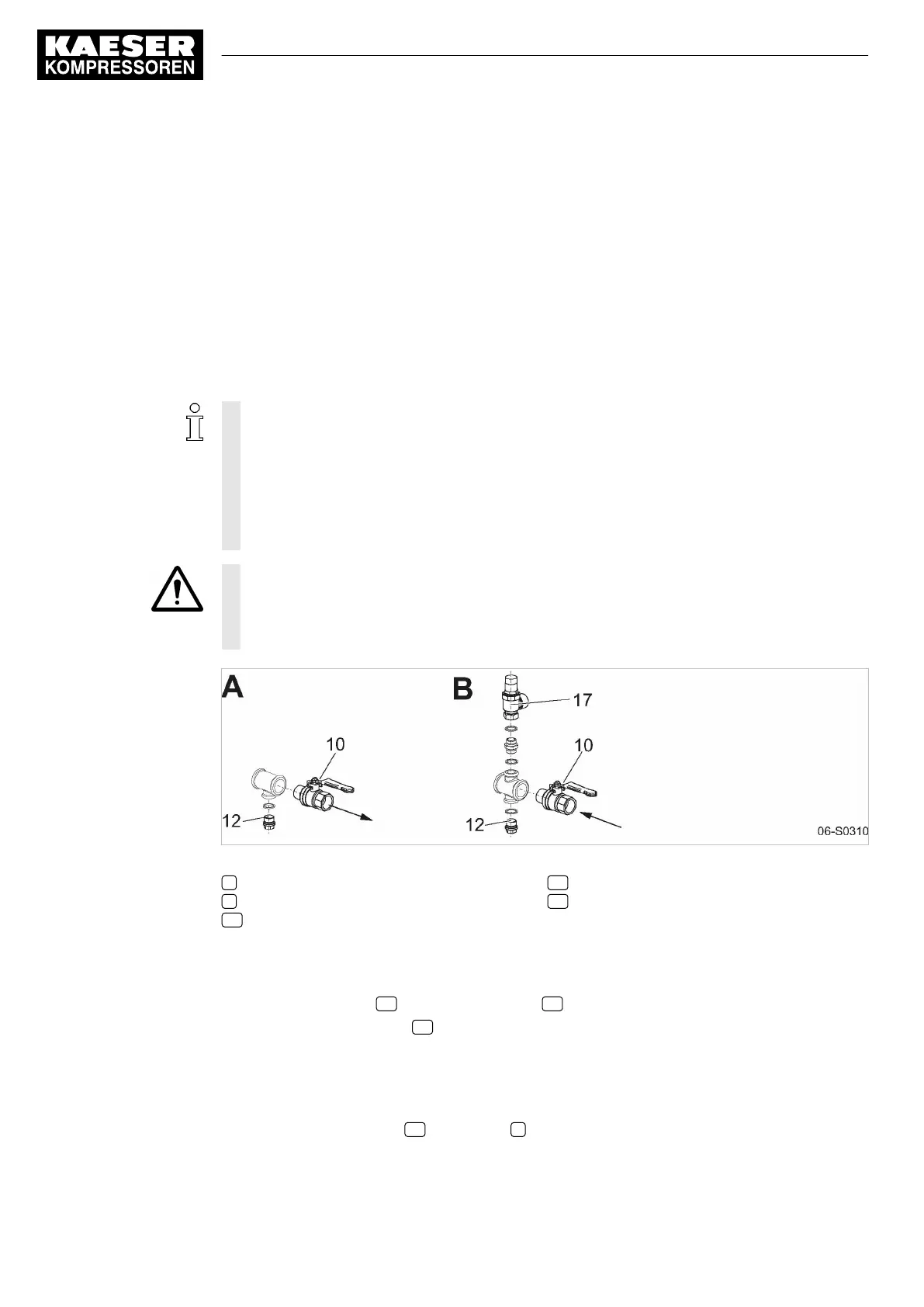

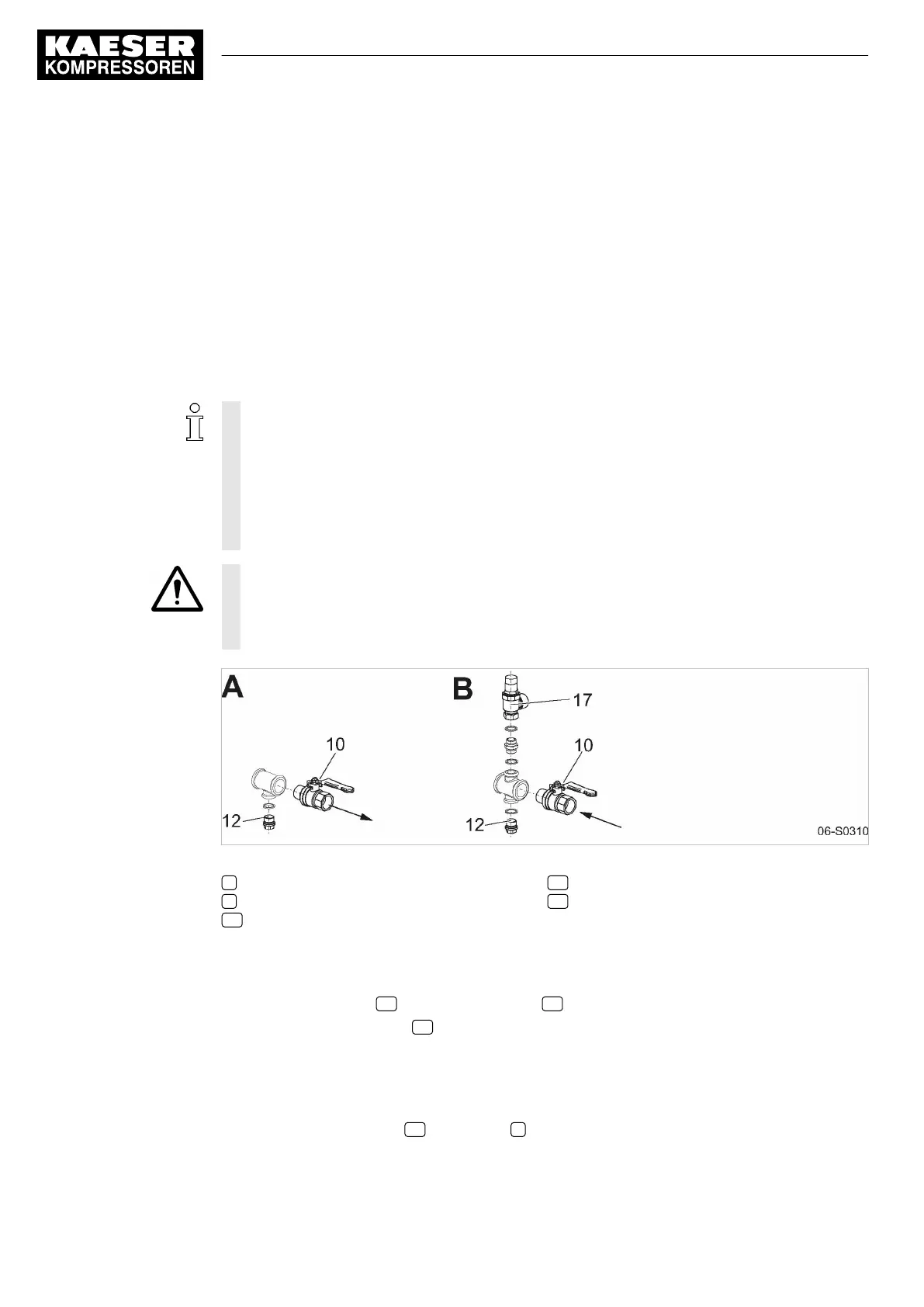

Fig. 12 Connecting the heat recovery system

A Outlet

B Inlet

10 Shut-off valve

12 Connection port with plug

17 Pressure relief valve

1. The user is to provide the following fittings:

■ Dirt trap with max. 0.1 mm strainer mesh

■ Shut-off valves 10 and connection ports 12 for maintenance and venting.

■ Pressure relief valve 17 to prevent build-up of excessive pressure.

Actuating pressure and blow-off capacity of the safety valve are governed by the user's in‐

stallation design. The technical specification of the heat exchanger must be taken into con‐

sideration.

2. Connect the supply lines and fittings.

3. Open the shut-off valve 10 at the outlet A .

6 Installation

6.6 Options

44

Operating Manual Screw Compressor

ASK 901824 12 E

Loading...

Loading...