10.15 Replenish cooling oil

The machine must be isolated from the compressed air network and completely vented be‐

fore undertaking any work on the pressure system.

Material The hose coupling, shut-off valve and maintenance hose required for venting lie beneath the oil

separator tank.

Precondition Cut-off the electrical power supply via the power supply isolating device,

ensure that the device is locked off,

verify the absence of any voltage.

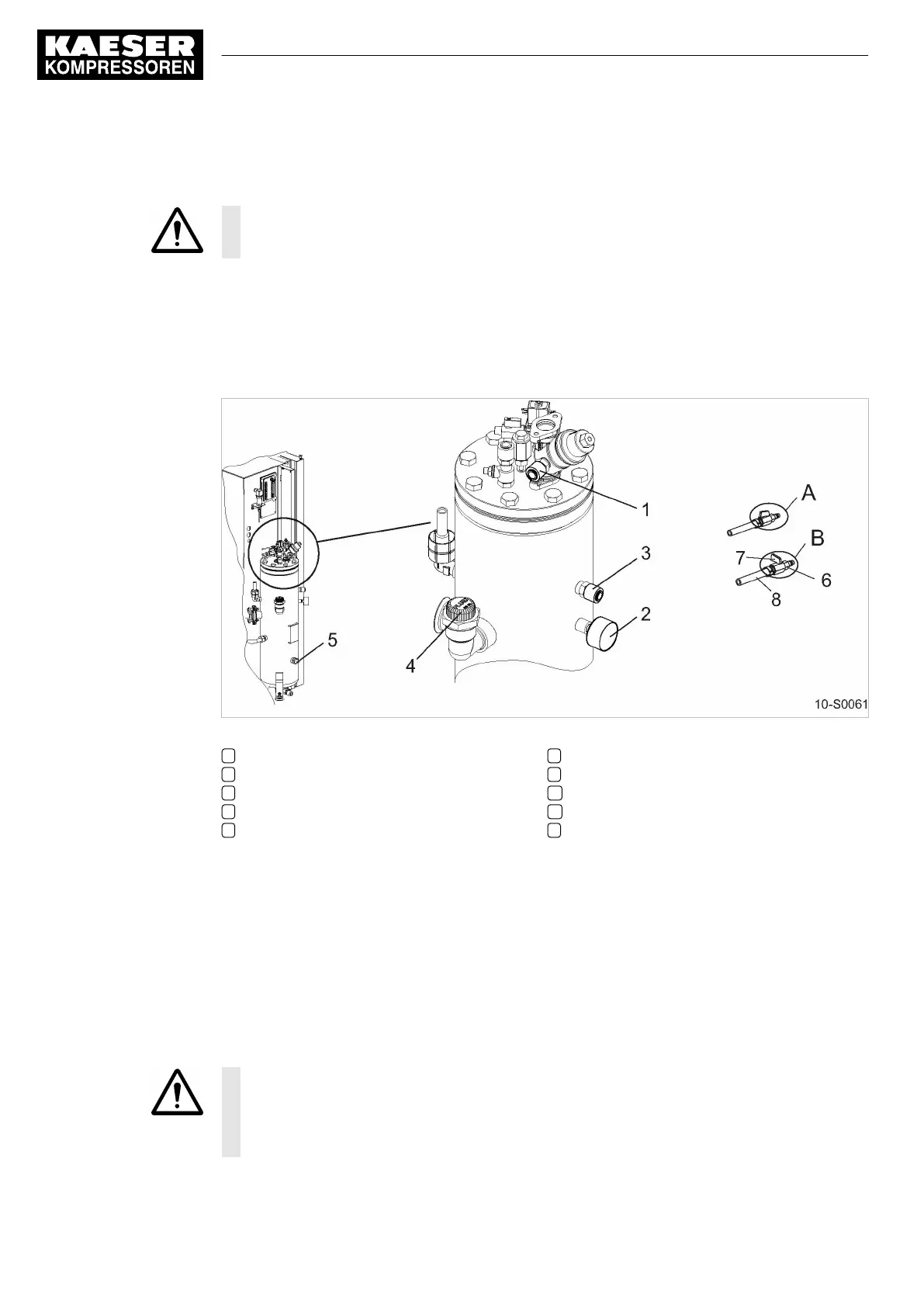

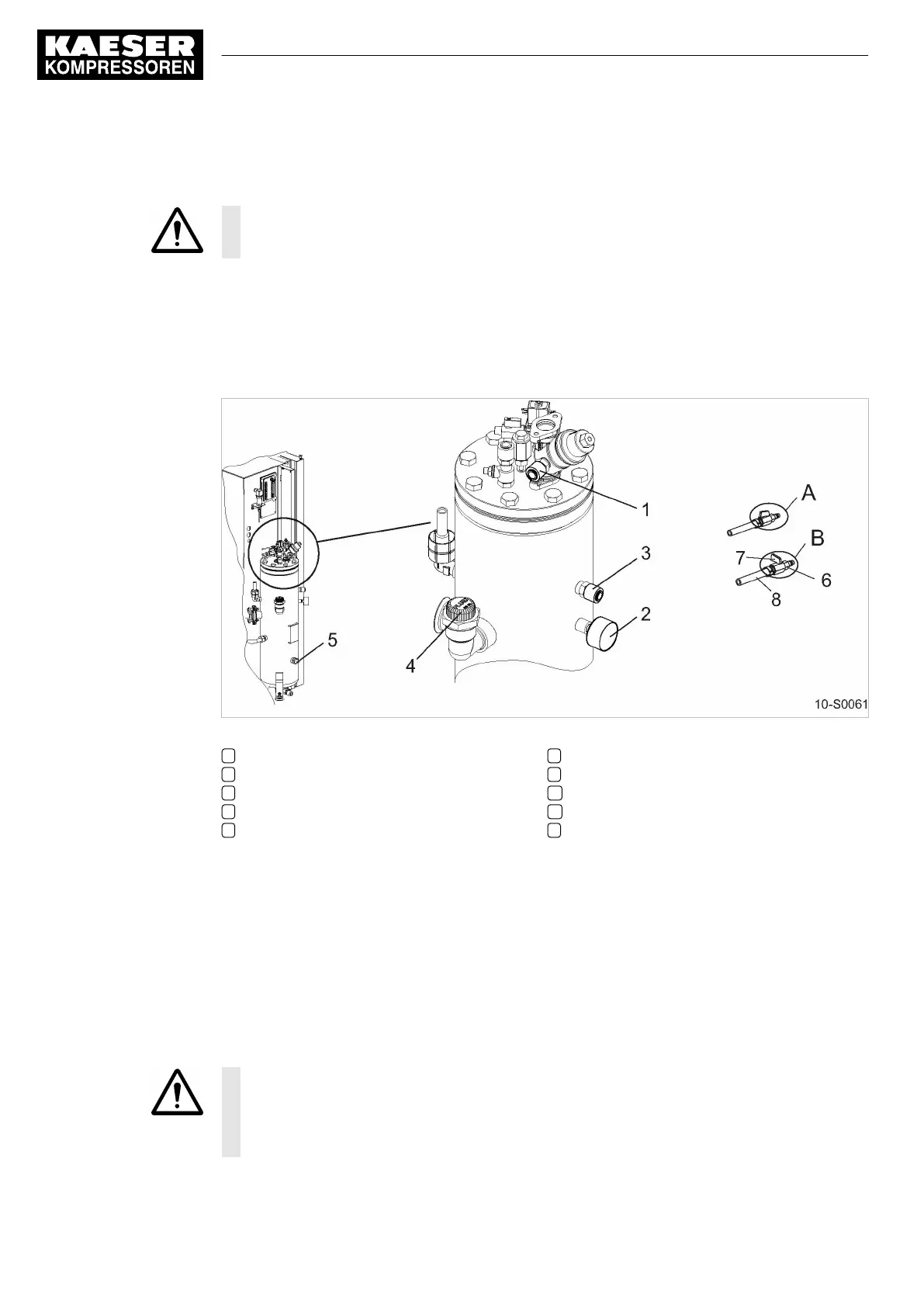

Fig. 28 Replenish cooling oil

1 Hose coupling (air cooler venting)

2 Pressure gauge

3 Hose coupling (oil separator tank venting)

4 Oil filler port with plug

5 Cooling oil level indicator.

6 Plug-in nozzle

7 Shut-off valve

A Shut-off valve open

B Shut-off valve closed

8 Maintenance hose

1. Vent the machine as described in section 10.15.1.

2. Fill with cooling oil and test run as described in section 10.15.2.

10.15.1 Venting the machine (de-pressurising)

Venting takes place in three stages:

■ Isolate the compressor from the air system.

■ Vent the oil separator tank.

■ Manually vent the air cooler.

CAUTION

Escaping oil mist is damaging to health.

➤ Do not direct the maintenance hose at persons while venting.

➤ Do not inhale the oil mist.

10 Maintenance

10.15 Replenish cooling oil

72

Operating Manual Screw Compressor

ASK 901824 12 E

Loading...

Loading...