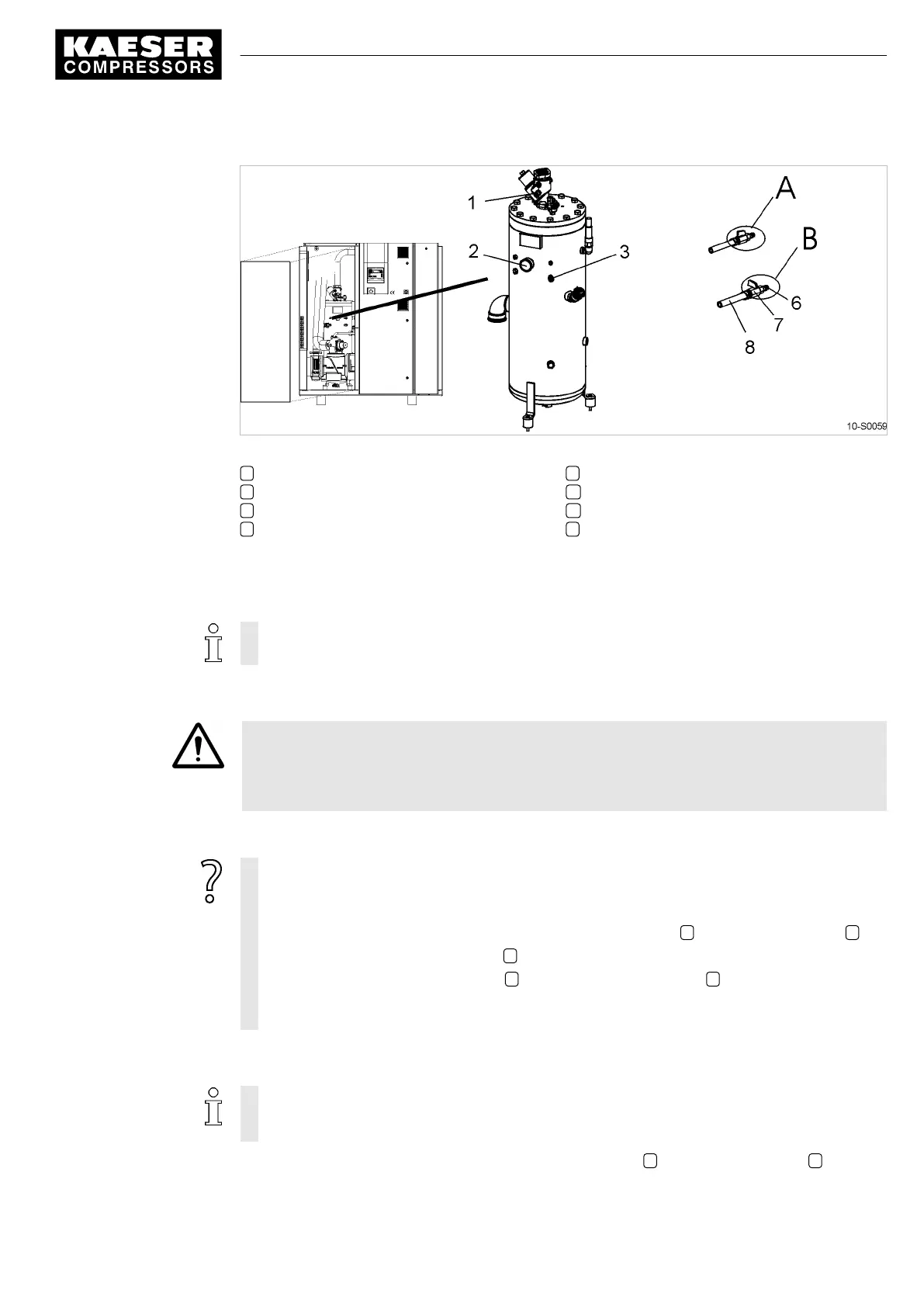

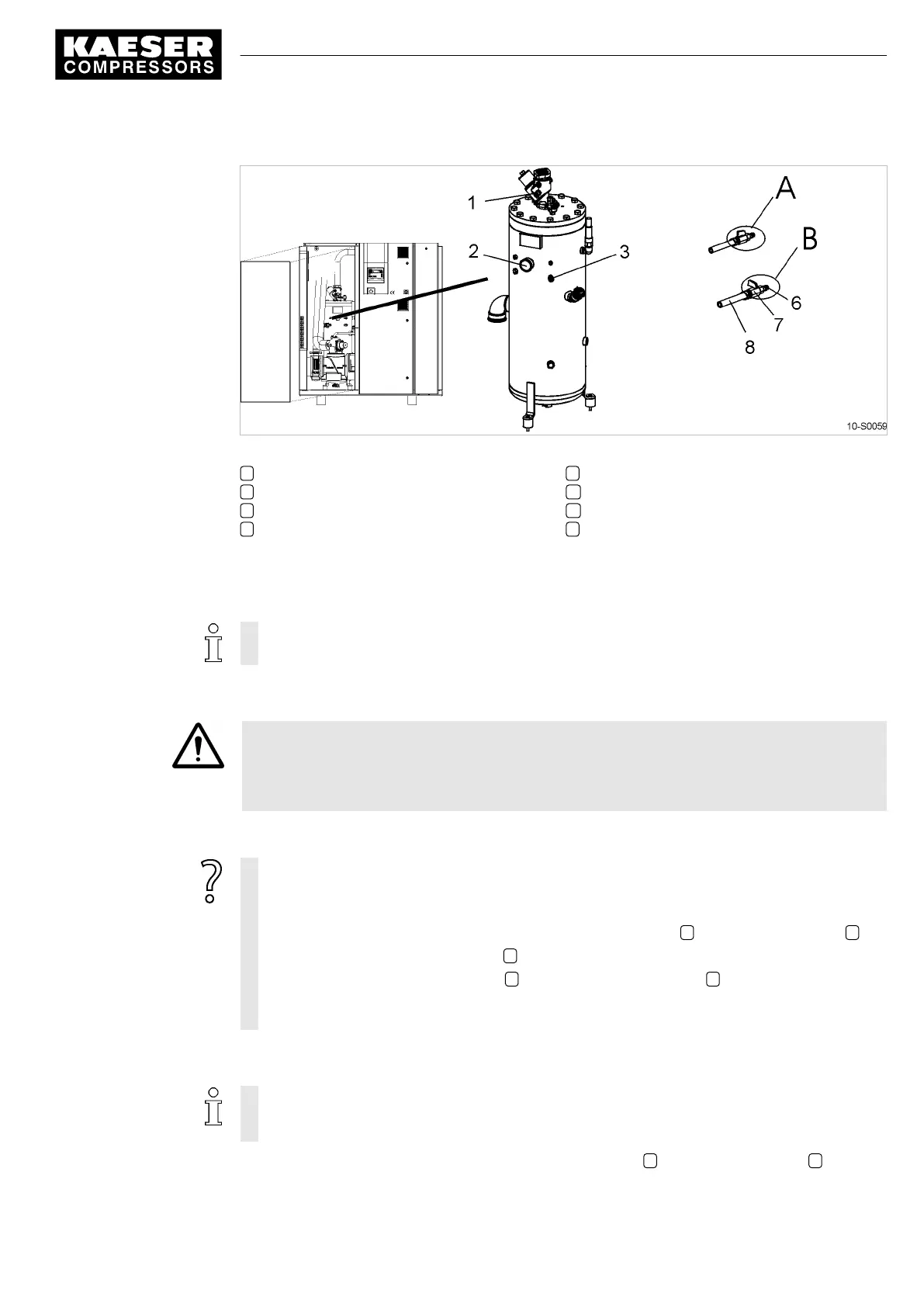

Fig. 30 Venting the machine

1 Hose coupling (air cooler venting)

2 Pressure gauge

3 Hose coupling (oil separator tank venting)

6 Male hose coupling/fitting

7 Shut-off valve.

A Shut-off valve open

B Shut-off valve closed

8 Maintenance hose

Isolate the machine from the compressed air system.

➤ Close the user's shut-off valve between the machine and the compressed air system.

If no shut-off valve is provided, the complete compressed air system must be vented.

Vent air from the oil separator tank.

WARNING

Escaping oil mist is damaging to health.

➤ Do not direct the maintenance hose at a person while venting.

➤ Do not inhale the oil mist.

➤ Check that the oil separator tank pressure gauge reads 0 psig.

After automatic venting the pressure gauge does not read zero?

➤ Make sure that the shut-off valve is closed or that the compressed air system is vented to

atmospheric.

➤ With the shut-off valve closed, insert the male hose fitting 6 into the hose coupling 3 .

➤ Slowly open the shut-off valve 7 to release pressure.

➤ Withdraw the male hose fitting 6 and close the shut-off valve 7 .

➤ If manual venting does not bring the oil separator tank pressure gauge to 0 psig, call an

authorized KAESER Service representative.

Vent air manually from the air cooler.

After shutting down the compressor and venting the oil separator tank, there is still pressure on

the machine from the compressed air system or in the section from the shut-off valve to the

minimum pressure/check valve.

1. With the shut-off valve closed, insert the male hose fitting 6 into the hose coupling 1 .

10 Maintenance

10.14 Venting the machine (depressurizing)

9_5708 08 USE

Service Manual Screw Compressor

BSD

75

Loading...

Loading...