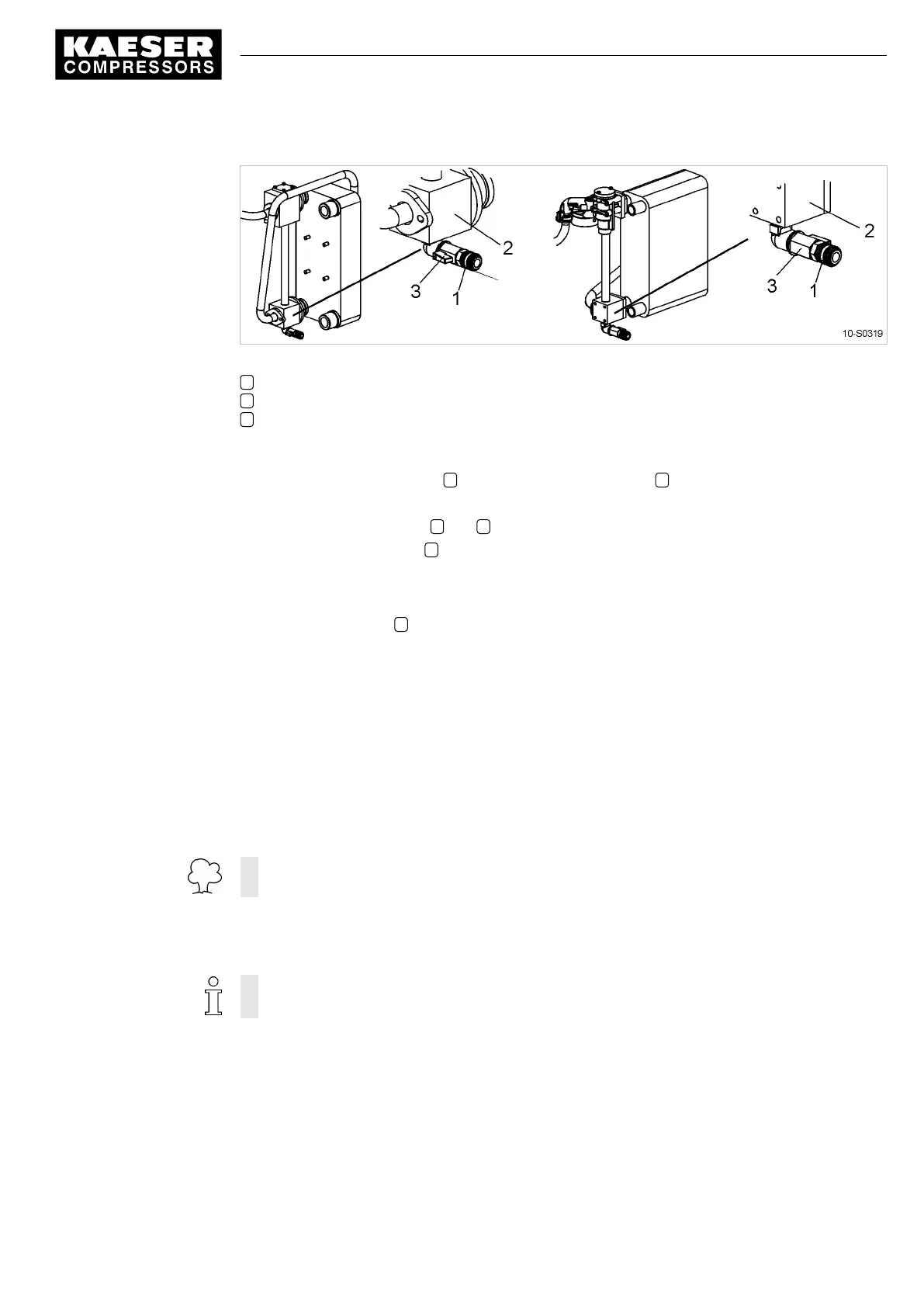

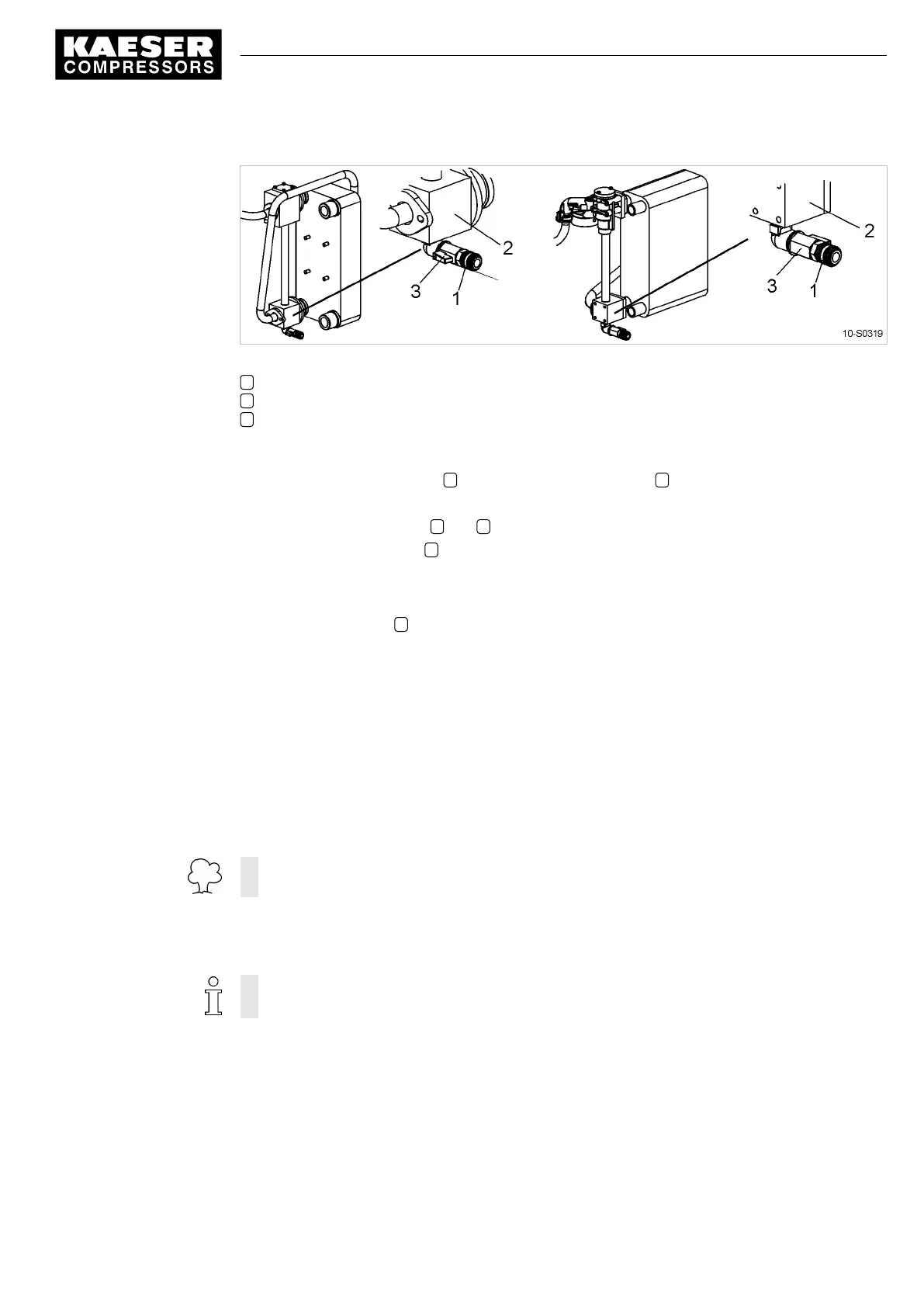

Fig. 36 Changing the cooling oil, heat recovery system

1 Hose coupling

2 Thermostatic valve

3 Shut-off valve

1. Have an oil receptacle ready.

2. Insert the male hose fitting 6 (Fig. 32) in the hose coupling 1 .

3. Place the other end of the maintenance hose in the oil receptacle and secure it in place.

4. Open the shut-off valves 3 and 7 (Fig. 32) and allow the oil to drain completely.

5. Close the shut-off valve 3 and unplug the male hose fitting.

Filling with cooling oil

1. Open the filler plug 4 (Fig. 32) slowly.

2. Fill with cooling oil.

3. Check the filler plug and ring seal for damage and screw the plug back in again.

Start the machine and carry out a trial run

1. Close all access doors; replace and secure all removable panels.

2. Open the user's shut-off valve between the machine and the air distribution network.

3. Switch on the power supply and reset the maintenance interval counter.

4. Start the machine and check the oil level again after about 10 minutes, topping up if necessary.

5. Switch off the machine and check visually for leaks.

➤ Dispose of used oil in accordance with environment protection regulations.

10.17 Changing the Oil Filter

The machine must be isolated from the compressed air system and completely vented before

undertaking any work on the pressure system.

Material Replacement part

Cooling oil container

Precondition The power supply disconnecting device is switched off

The disconnecting device is locked in the off position

A check has been made no voltage is present

The machine is fully vented, the pressure gauge reads 0 psig.

10 Maintenance

10.17 Changing the Oil Filter

9_5708 08 USE

Service Manual Screw Compressor

BSD

83

Loading...

Loading...