"This is a message indicating that the instrument is not

calibrated properly, since calibration constants are stored in

NVRAM. The Model 197 remains at this point

if

the test fails,

but operation may be restored

for

troubleshooting by press-

ing either the

REL,

dB

or

DATA Logger buttons. The flashing

"C" annunciator indicates that the unit failed the NVRAM

test.

At this point try calibrating the instrument with the constants

already entered by simultaneously pressing

REL

and dB until

the CAL message is displayed. Then release the

REL

and dB

buttons. Simultaneously press the

REL

and dB buttons again

until the STOR message is displayed.

If

the error is corrected,

indicating that the NVRAM is probably good, a full calibra-

tion is required.

If

the error persists try replacing the NVRAM

chip,

U113.

Again the Model 197 must be completely

recalibrated after the problem is corrected.

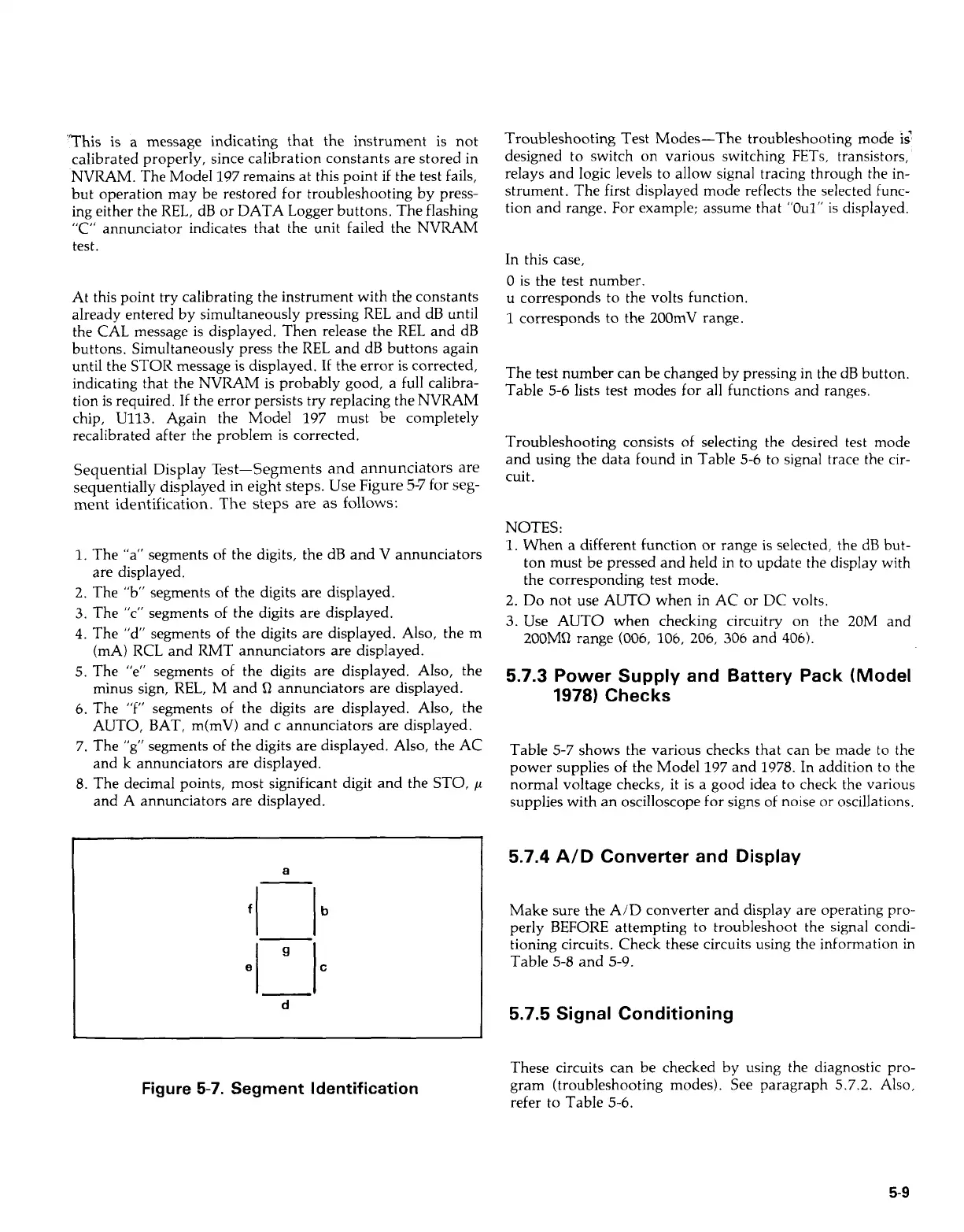

Sequential Display Test-Segments and annunciators are

sequentially displayed in eight steps. Use Figure

5-7

for

seg-

ment identification. The steps are

as

follows:

1.

The "a" segments of the digits, the dB and V annunciators

2. The "b" segments

of

the digits are displayed.

3.

The "c" segments of the digits are displayed.

4.

The "d" segments

of

the digits are displayed. Also, the m

(mA)

RCL

and

RMT

annunciators are displayed.

5. The "e" segments of the digits are displayed. Also, the

minus sign,

REL,

M and

Q

annunciators are displayed.

6.

The

"f"

segments of the digits are displayed. Also, the

AUTO, BAT, m(mV) and c annunciators are displayed.

7.

The

"g"

segments of the digits are displayed. Also, the AC

and k annunciators are displayed.

8.

The decimal points, most significant digit and the STO,

p

and A annunciators are displayed.

are displayed.

a

fl-I

9

C

el

I

d

Figure

5-7.

Segment Identification

Troubleshooting Test Modes-The troubleshooting mode

is'

designed to switch on various switching

FETs,

transistors,

relays and logic levels to allow signal tracing through the in-

strument. The first displayed mode reflects the selected func-

tion and range. For example; assume that

"Oul"

is displayed.

In this case,

0 is the test number.

u

corresponds to the volts function.

1

corresponds to the 200mV range.

The test number can be changed by pressing in the dB button.

Table

5-6

lists test modes for all functions and ranges.

Troubleshooting consists

of

selecting the desired test mode

and using the data found in Table

5-6

to signal trace the cir-

cuit.

NOTES:

1.

When a different function

or

range is selected, the dB but-

ton must be pressed and held in to update the display with

the corresponding test mode.

2. Do not use AUTO when in AC

or

DC volts.

3.

Use AUTO when checking circuitry on the 20M and

200MQ range

(006,

106,

206,

306

and

406).

5.7.3

Power Supply and Battery Pack (Model

1978)

Checks

Table 5-7 shows the various checks that can be made to the

power supplies

of

the Model 197 and 1978. In addition

to

the

normal voltage checks, it is a good idea to check the various

supplies with an oscilloscope for signs of noise

or

oscillations.

5.7.4

A/D Converter and Display

Make sure the A/D converter and display are operating

pro-

perly BEFORE attempting to troubleshoot the signal condi-

tioning circuits. Check these circuits using the information

in

Table 5-8 and 5-9.

5.7.5

Signal Conditioning

These circuits can be checked by using the diagnostic pro-

gram (troubleshooting modes). See paragraph 5.7.2.

Also,

refer to Table 5-6.

5-9

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...