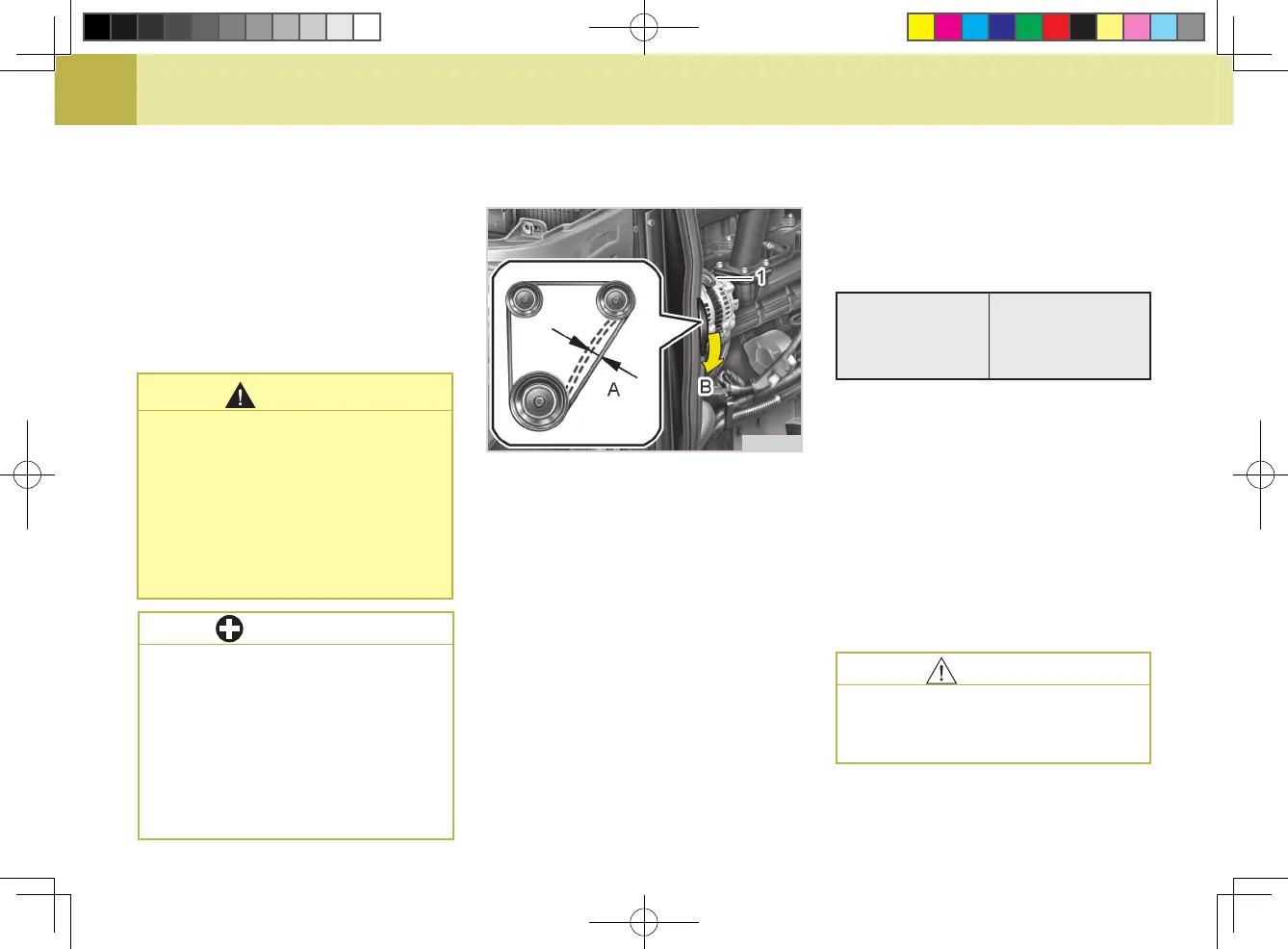

(1) Adjusting Bolt

(A) Adjusting Belt Tension (B) Pull

ADJUSTING FAN BELT TEN-

SION (V)

In order to extend the fan belt’s life-

time, the tension of the belt should

be correctly adjusted if it slips. The

belt tension should be inspected reg-

ularly according to the following pro-

cedure:

1. Stop the engine and apply the

parking brake.

2. Open the hood and remove the

left side cover.

3. If the fuel pipes and hose clamps

are found damaged or deterio-

rated earlier than two years, then

change them immediately.

4. A f te r t he f ue l p ip e a n d h os e

clamps have been changed, bleed

the fuel system.

Stop the engine when check-

ing the items above.

The fuel pipes are subject to

wear and aging. Failure to per-

form periodic inspections may

lead to a fuel leak. Fuel leaking

on a hot engine could cause a

re.

When changing fuel pipes, be

careful not to allow dust or dirt

to enter the fuel system. Con-

taminations in the fuel system

could damage the fuel sys-

tem or injection pump. Pay ex-

tra caution to the fuel pump to

prevent dust from entering it.

IMPORTANT

WARNING

H61O730A

3. In order to measure the belt ten-

sion, apply thumb pressure strong-

ly to the “A” location of belt.

Belt deection for

proper fan belt

tension (A)

7 ~ 9 mm

(0.28 ~ 0.35 in.)

4. If tension is incorrect, loosen the

alternator mounting bolt and hinge

bolt. Pull the alternator outward

using a pry to reach to the proper

belt tension.

5. Be sure to retighten the alternator

mounting bolt and hinge bolt se-

curely after adjusting belt tension.

6. Replace the fan belt if it is dam

-

aged, cracked or worn.

To avoid personal injury:

Be sure to stop the engine be-

fore checking belt tension.

CAUTION

Loading...

Loading...