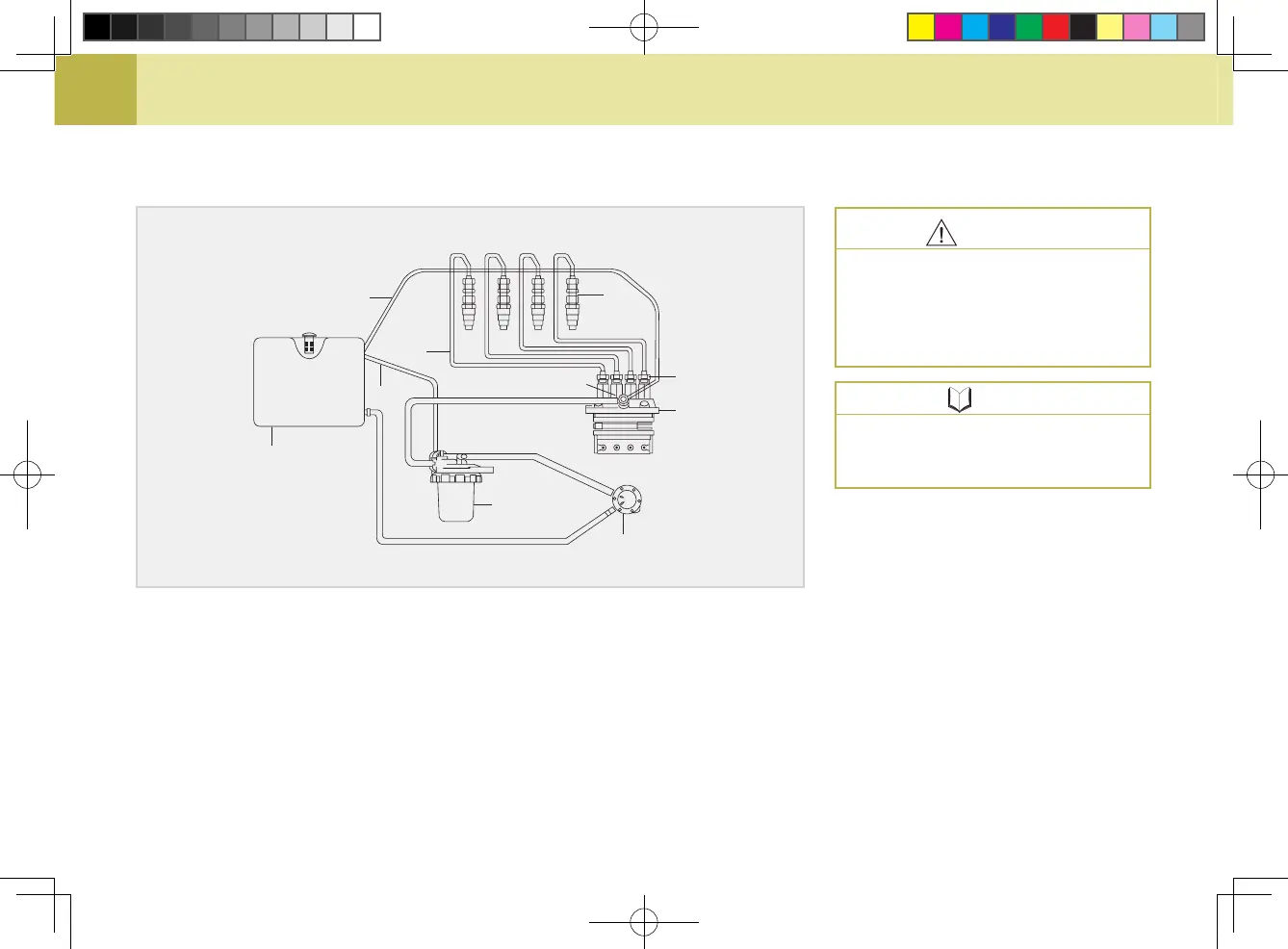

T46W233A

(1) Fuel Tank

(2) Fuel Filter

(3) Fuel Injection Pump

(4) Injection Pipe

(5) Injection Nozzle

(6) Fuel Overow Pipe (Hose)

(7) Fuel Feed Pump

(8) Bleeding Bolt

(9) Bleeding Hose

(10) Nozzle Holder Nut

2. If there is air in the fuel lter, turn the lter cock to the air side and turn

the ignition key to turn the start motor. Then, the air in the lter port is dis-

charged through the bleeding hose as shown in the gure.

3. When the amount of the fuel in the fuel lter port goes over 3/4 level, stop

cranking the engine and turn the cock in the gure to the “ON” (open) posi-

tion.

4. Unscrew the bleeding bolt in the

figure and crank the engine to

bleed the system. Then, tighten

the bolt.

5. If the engine still cannot be started

even after performing the above

step, unscrew the 1 or 2 nozzle

holder nuts out of 3 or 4 and crank

the engine to bleed the system.

6. When air bubbles aren`t seen any-

more in the drained fuel, tighten

the loose parts and start the en-

gine.

It is not necessary to bleed the

system if lling the pot with fuel

before installing the fuel lter.

Do not operate the start motor

for more than 10 seconds con-

tinuously. Instead, operate it

for several times within 10 sec-

onds each time.

CAUTION

NOTE

Loading...

Loading...