77

0

50

100

150

200

250

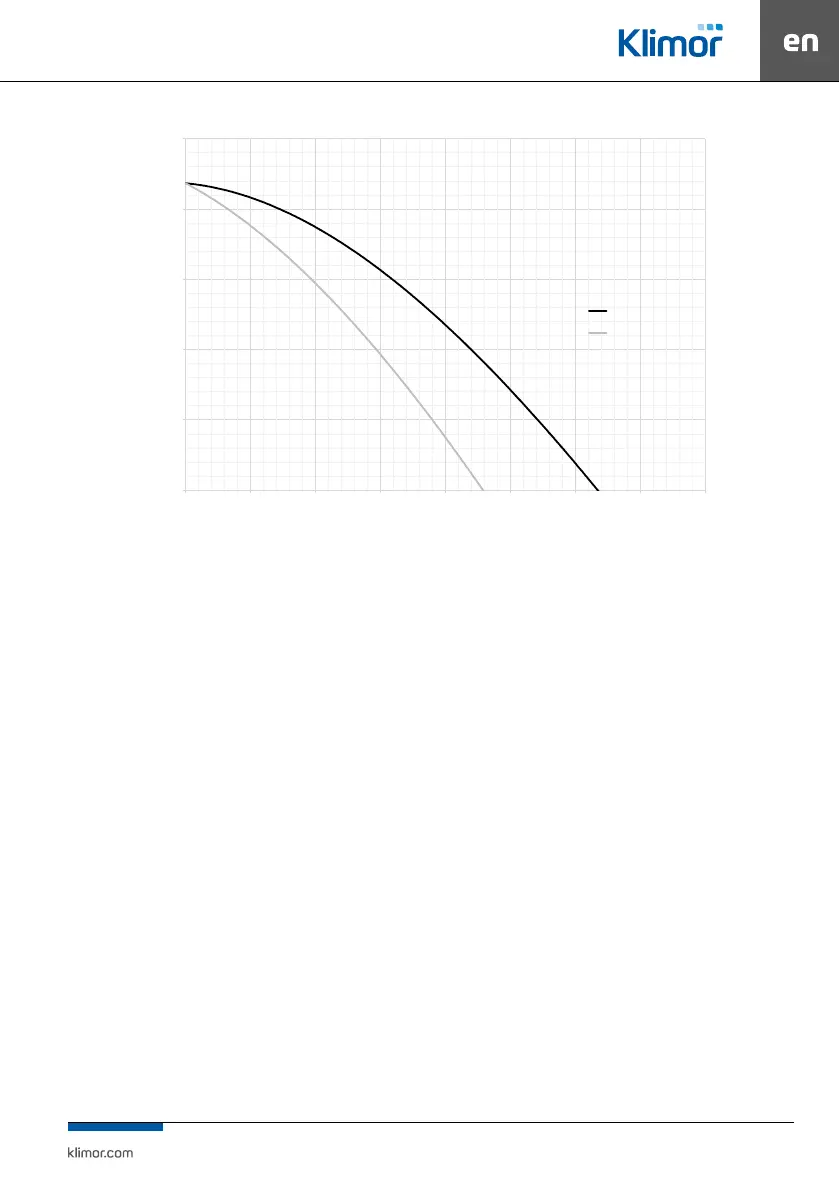

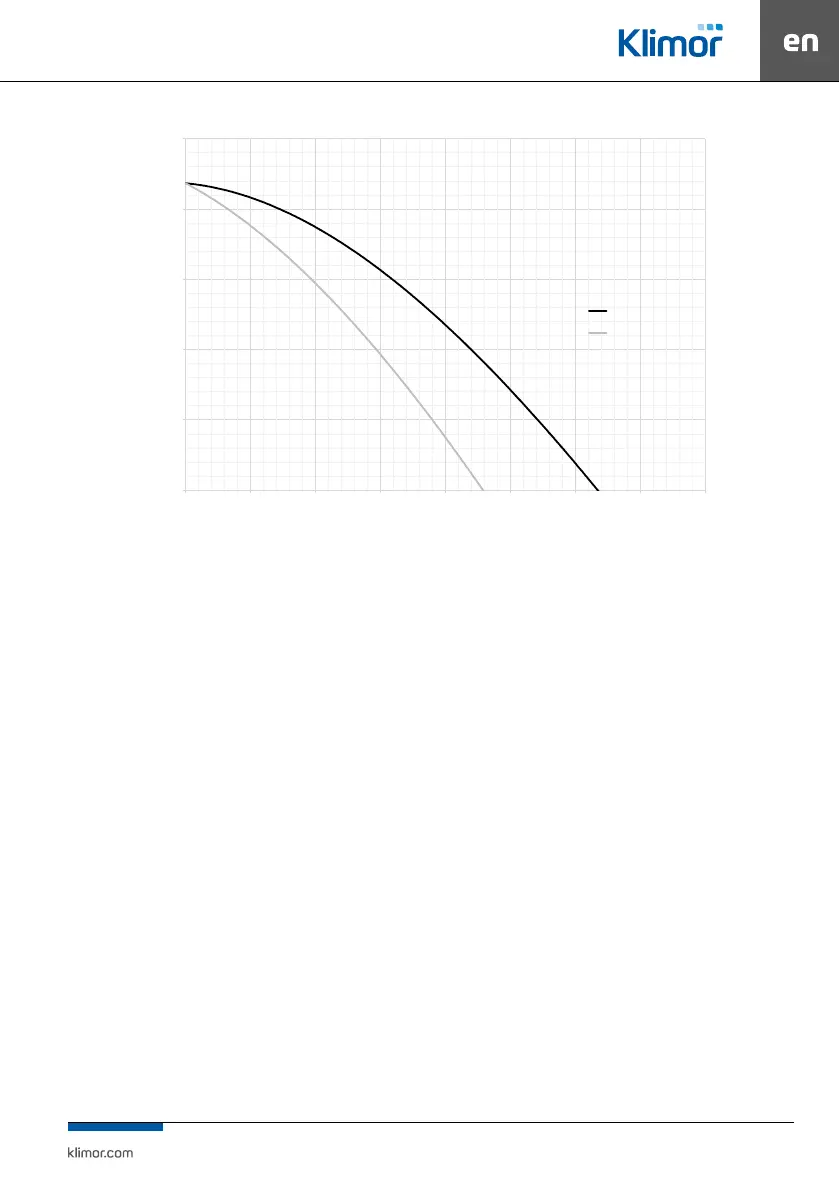

0 100 200 300 400 500 600 700 800

Ciśnienie dyspozycyjne [Pa]

Wydatek powietrza [m

3

EVO-T+ 3000 CPR

EVO-T+3000 RR

Diagram 3 Technical parameters EVO-T+ 3000. NOTE: The graph does not show the characteristics with the optional lter ePM1 60%.

3. CONFIGURATIONS, COMPONENTS, EXECU

TION SIDE

Congurations:

L – horizontal version

R/L – right-hand execution side R/left-hand execution side L

P – parallel air ow

C – cross-ow

Components:

VF – Fan

PF – Filter

CPR – cross-ow heat exchanger

RR – rotary heat exchanger

WH/EH – water heater/ electric heater (option to choose).

Example of designation:

1) EVO-T+ 3000 CPR_L-C-EH/L – EVO-T+ size 3000 air

handling unit with CPR counterow heat exchanger,

recessed version, cross air ow, electric heater, left-

hand execution side.

2) EVO-T+ 3000 RR-P-WH/R – EVO-T+ 3000 size air

handling unit with RR rotary exchanger, suspended

version, parallel air ow, water heater, right-hand side

execution.

AIR FLOW CHARACTERISTICS EVOT+ 3000

4. AHU CONSTRUCTION

Housing – Self-supporting housing made of 0.7 mm thick

galvanised sheet metal, inner and outer U-bend. The space

between the casing metal sheets is lled with mineral wool

insulation board. The casing is closed by means of inspec-

tion covers, which allow easy access to the equipment com-

ponents. Flexible connections are tted as standard on all

inlets and outlets of the unit. As an option the air handling

unit can be equipped with shut-o dampers (air intake,

outlet) and diusers (rectangular / circular).

Fans – radial-axial with direct drive – EC motor, 0÷10V con

-

trol.

Secondary Heater – electric heater equipped with an over-

heating protection thermostat or water heater equipped

with an antifreeze thermostat.

Heat exchanger – counterow heat exchanger with by-

pass or rotary exchanger

Air lter – disposable, replaceable, class Coarse 80% (G4);

optional: ePM10 class 50% (M5). Optionally a lter of ePM1

class 60% (F7) may be used on the supply air.

Control system – supplied

EXTERNAL AVAILABLE PRESSURE PA

AIR FLOW M

3

/H

Loading...

Loading...