81

During temperatures below 0°C and when the air supply

fan is turned o as a protecting and anti-frost function,

a short-term subatmospheric (negative) pressure will be

formed in rooms, since only air exhaust fan is operating

If the AHU installation and operation guidelines stated

above are not followed, the EVO-T+ AHUs may not operate

in line with requested parameters and humidity condensa-

tion may occur inside the unit as well as at their external

casing surfaces. If the unit is damaged and the phenomena

described above occur due to non-compliance with the re-

quirements set by the manufacturer it will result in loss of

manufacturer’s warranty

Compact Units

The unit is to be suspended with the use of handles moun-

ted on the sides of the casing. A M8 threaded bar is inserted

into the lower part of the handle (U1) and a nut with a wa-

sher is screwed on. Next, the bar is inserted into the groove

of the upper part of the handle (U2), and at the same time

they are joined together by pushing the U1 element into

the U2 element at the bottom. The use of M8 threaded bars

enables easy and quick suspension and levelling o of the

particular modules of the unit. The M8 threaded bars are

not delivered.

The minimum retained distance of the upper surface of the

unit to the partition should be 20mm (Fig. Nr 4)

Fig. 4 Installation of EVO- T+ in suspended position.

Air handling unit operation with service access from above

in a horizontal design.

The air handling unit should be located on a levelled, stable

surface. Because of the necessity of draining condensate

(installation of a siphon) it is advisable to base it on asup-

porting construction, e.g. a frame adjusted to the size of

the air handling unit (supporting construction is not sup-

plied by Klimor). Mounting using standard slings and M8

threaded rods xed to the oor is permissible and is shown

below. The minimum installation height of the EVO-T+ CPR

is 120 mm.

Fig. 5 Mounting EVO- T+ in the horizontal working position.

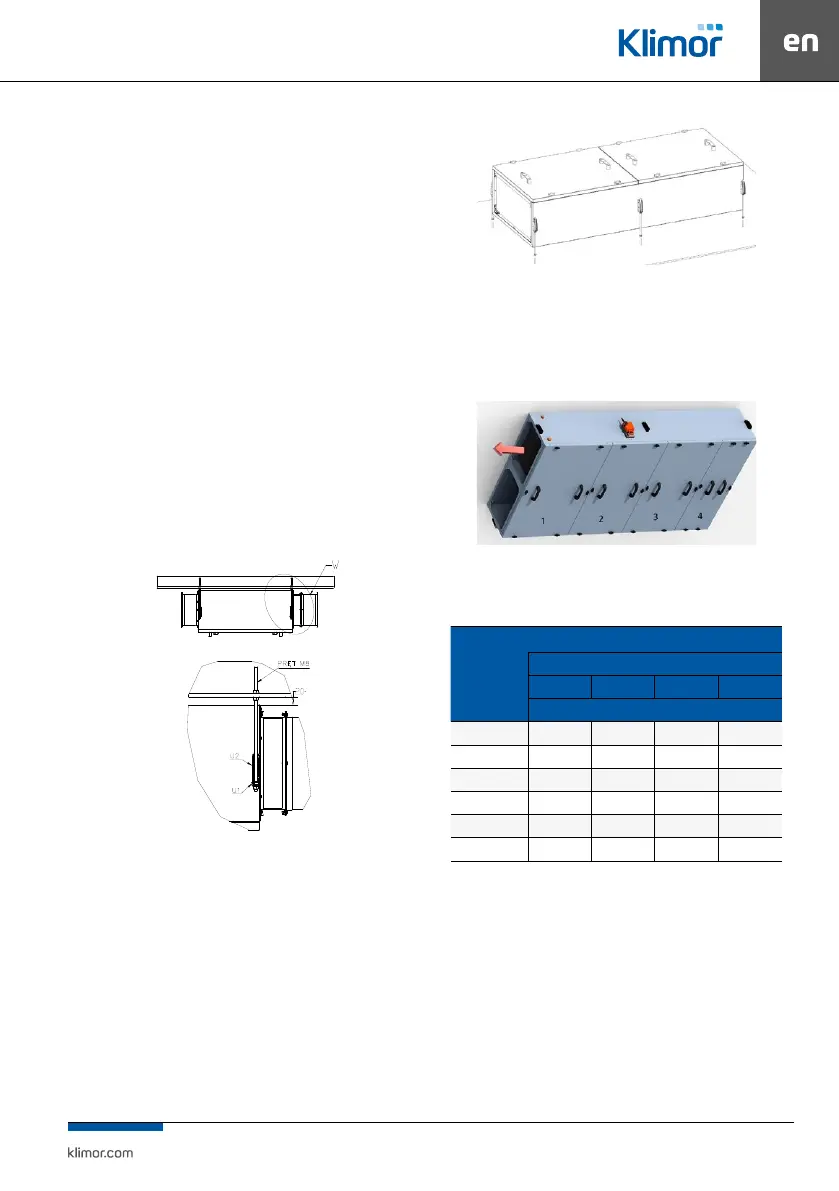

7.2 Inspection covers

When determining the place of installation of the device,

attention should be paid to easy access for maintenance

and servicing.

Fig. 6 Location of EVO-T+ inspection covers.

Table 4 Dimensions of inspection covers

EVO-T+

INSPECTION COVER

No. of the cover

1 2 3 4

mm

8000-CPR 573 x 1012 483 x1012 483 x 1012 313 x 1012

5000-CPR 808 x 712 588 x 712 -- --

3000-CPR 758 x 612 538 x 612 -- --

8000-RR 573 x 1012 573 x 1012 483 x 1012 --

5000-RR 728 x 712 568 x 712 -- --

3000-RR 678 x 612 518 x 612 -- --

7.3 Connection of air ducts.

Air ducts are connected to the air handling unit through

exible connections. They counteract vibration transfers

and compensate for minor deviation in the mutual position

of the duct and a unit. Ventilation ducts should be connect-

ed with the joint anges in the corners by means of bolts. In

order for the elastic connection to work properly, the joint

sleeve should be extended for a minimum of 110 mm. The

“earth” of the unit casing should be electrically connect-

ed with the “earth” of the ventilation network. Ventilation

ducts should have their own supports or suspensions. If in

close proximity to the air handling unit outlet there will be

elbows of the duct, it is recommended that they have the

direction matching the direction of the fan rotation.

Loading...

Loading...