2RV/2RW/2RX/2RY/3RA-3

7-27

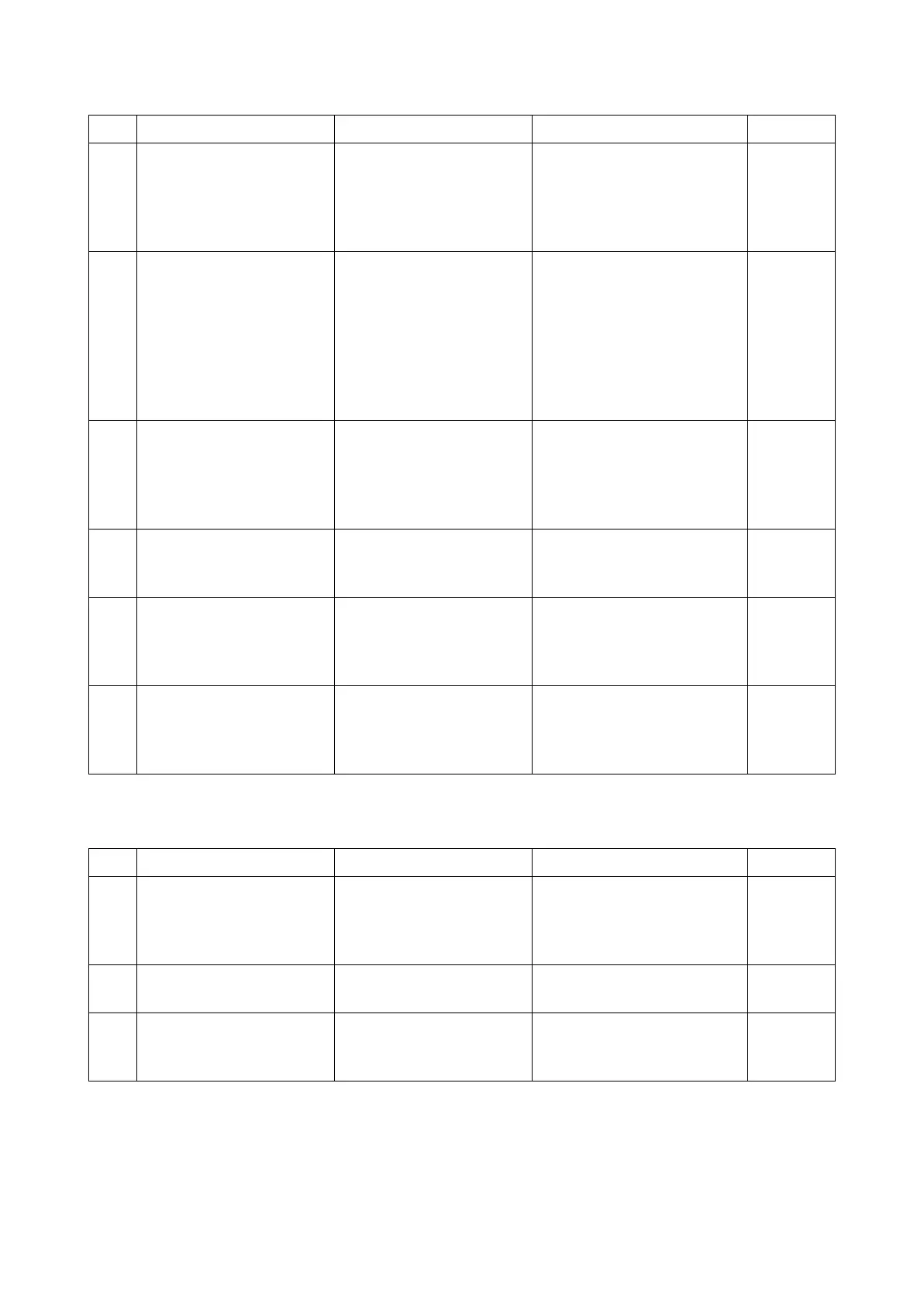

(1-7) Paper jam caused by conveying rollers and pulleys

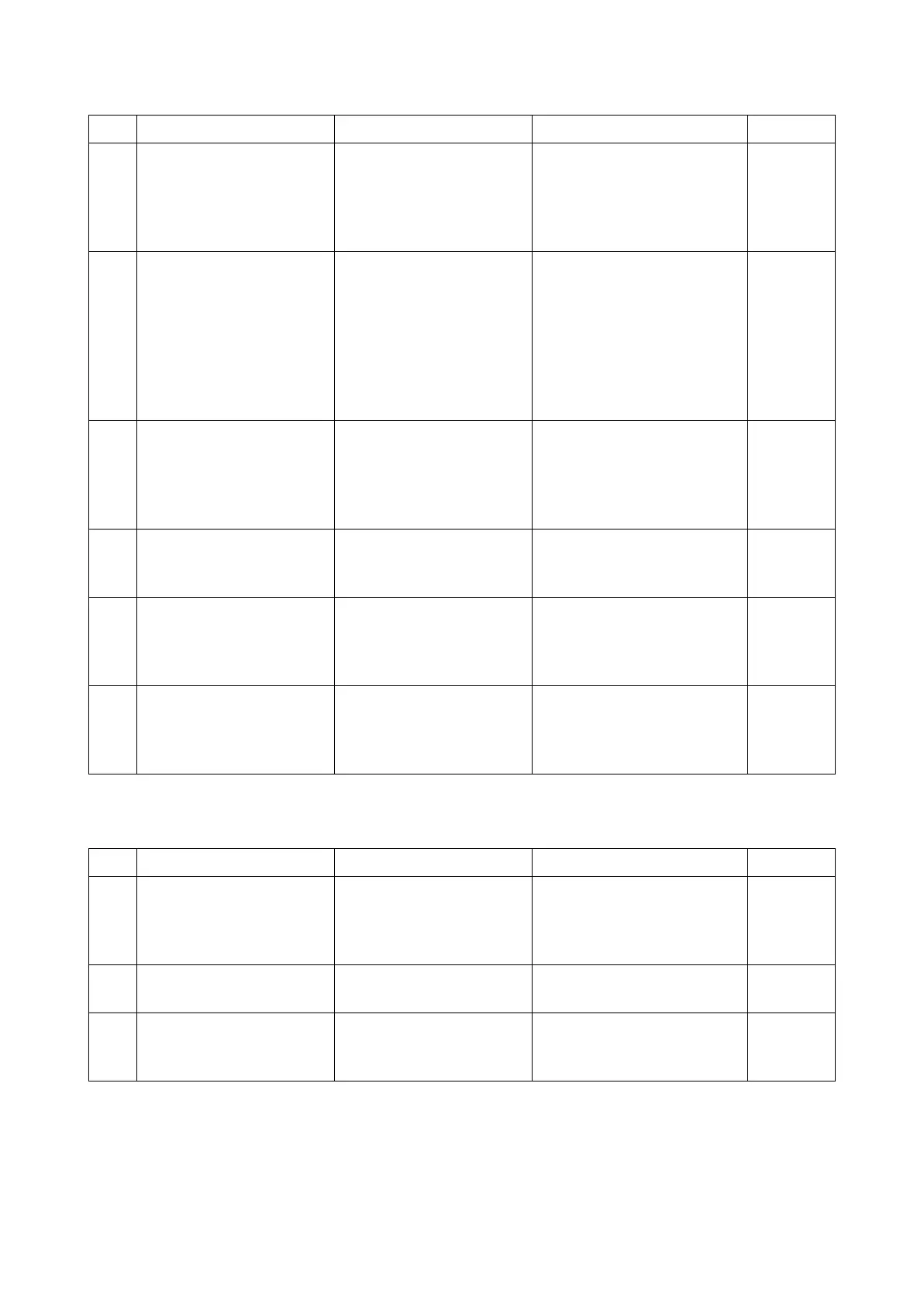

(1-8) Paper jam due to the sensor

Step Check description Assumed cause Measures Reference

1 Cleaning / replacing the

roller and pulley

The roller and pulley are

dirty.

If paper dust, toner or foreign

object adheres to the roller or

pulley, clean it. If there is vari-

ation in the external diameter

or wear, replace it.

2 Operation check The clutch does not oper-

ate properly.

Test print and check the

related motor operation with

the operation sound. Check

the clutch operation. If the

clutch does not operate, go to

the next step. (If the motor

operation is faulty, execute

the treatment by jam code.)

3 Checking the clutch The clutch is not attached

properly, connector is not

connected properly or for-

eign objects adhere to the

clutch.

Reattach the clutch and

reconnect the connector. If

foreign objects adhere to the

clutch, clean it to remove.

4 Replacing the clutch The clutch is faulty. Replace the clutch (individ-

ual clutch or unit including the

clutch).

5 Cleaning the roller shaft

and bushing

The roller shaft or bushing

is dirty.

If more load is applied to the

conveying rollers due to dirt

on the roller shaft and bush-

ing, clean there.

6 Reattaching the spring The spring comes off. Check if the spring came off,

or if it adequately presses the

roller or the pulley, and reat-

tach it if necessary.

Step Check description Assumed cause Measures Reference

1 Checking the actuator and

the spring

The actuator or spring

does not operate properly.

If the sensor actuator is

caught up or comes off, reat-

tach the actuator or spring. If

deformed, replace them.

2 Cleaning the sensor The sensor is dirty. If the sensor surface is dirty,

clean it.

3 Reattaching / replacing the

sensor

The sensor is faulty. Reattach and reconnect the

sensor. If not repaired,

replace it.

Loading...

Loading...