FLAPS_V6_HBR_datasheet_manual_EN.odt

6 Errors and faults, troubleshooting

6.1 Indicated errors and faults

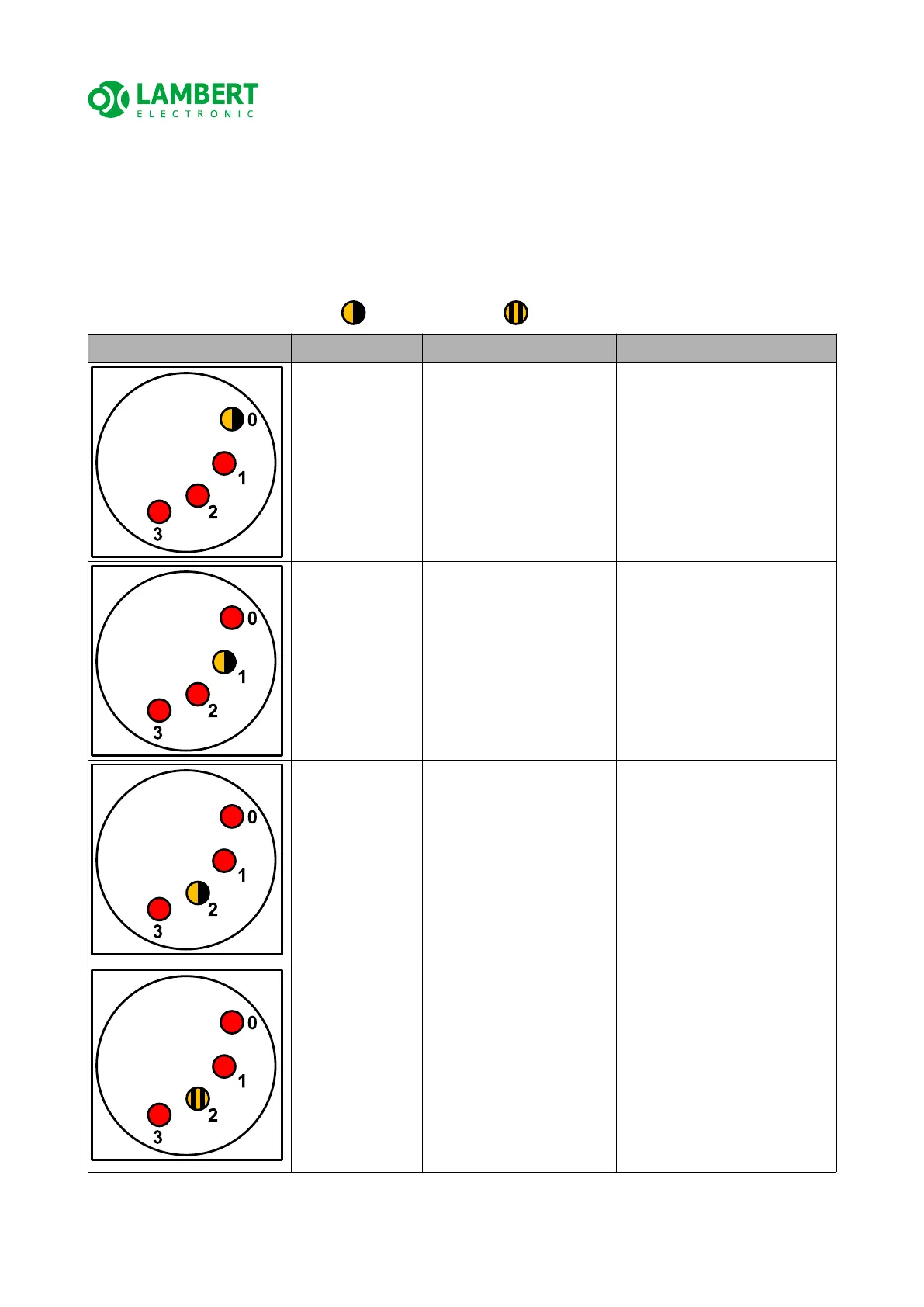

The FLAPS V6 HBR control unit can indicate up to 4 types of serious faults. The table

below lists these faults, their indications, and a more detailed description. Individual errors

are indicated by orange blinking of the LED and the other LEDs are red.

Blinking can be slow (1x/s ) or fast (5x/s ).

Indication Fault name Description & Cause Solution

Programmed

Positions

Error

The programmed

positions of the target

positions are shuffled or

overlapped. It often

occurs when

reprogramming target

positions mirrored

against factory preset.

Reprogram all target

positions one after the

other so that the positions

of the target positions go

gradually and do not

overlap (i.e. positions on

the piston rod distance

<2mm)

Position

Sensor Fault

Poor connection, short

circuit, or disconnection

of the position sensor

circuit. This may be due

to a fault in the wiring

or the position sensor,

in rare cases in the

control unit.

In flight, turn the switch to

position 1 or 2 to activate

the Safety Manual mode

(see Chapter 5.3).

On the ground, check the

wiring and functionality of

the position sensor.

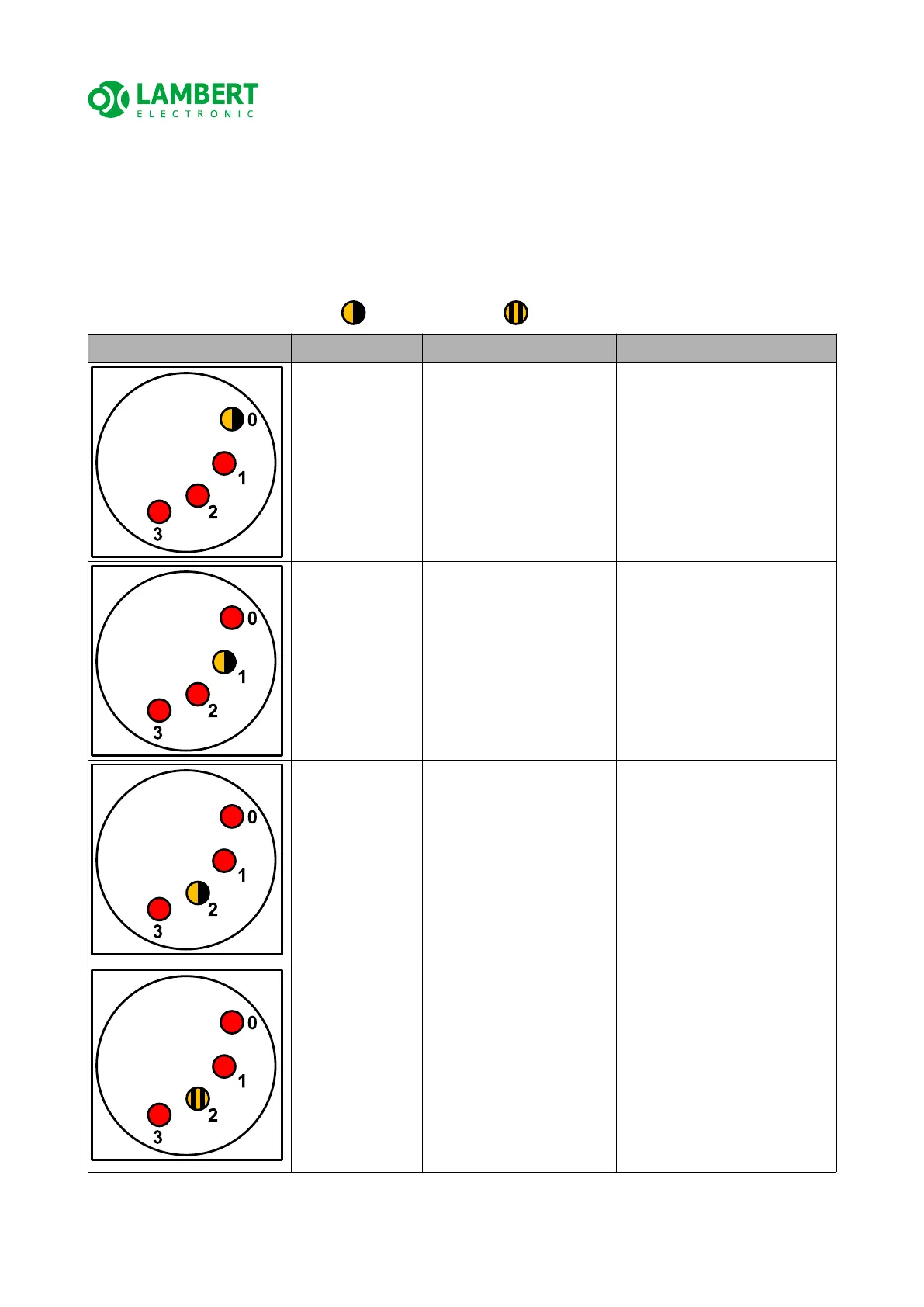

Error

Low Voltage

Weak battery or long

leads to FLAPS V6 unit

with too high voltage

drop at high actuator

load

Check the current-carry

dimensioning of the on-

board power network,

battery condition, shorten

the leads to the FLAPS V6

unit, the leads to the

actuator (if necessary,

increase the cross-sections

of the wires if the leads

cannot be shortened)

Error

Undervoltage

Low battery or wiring

fault

Check the wiring, the

current-carry dimensioning

of the on-board power

network, battery condition,

shorten the connections to

the FLAPS V6 unit, the

connections to the actuator

(if necessary, increase the

wire cross-sections if the

leads cannot be shortened)

29/33

Loading...

Loading...