9300 Servo PLC

Appendix

3-7

l

ServoPLC EN 2.0

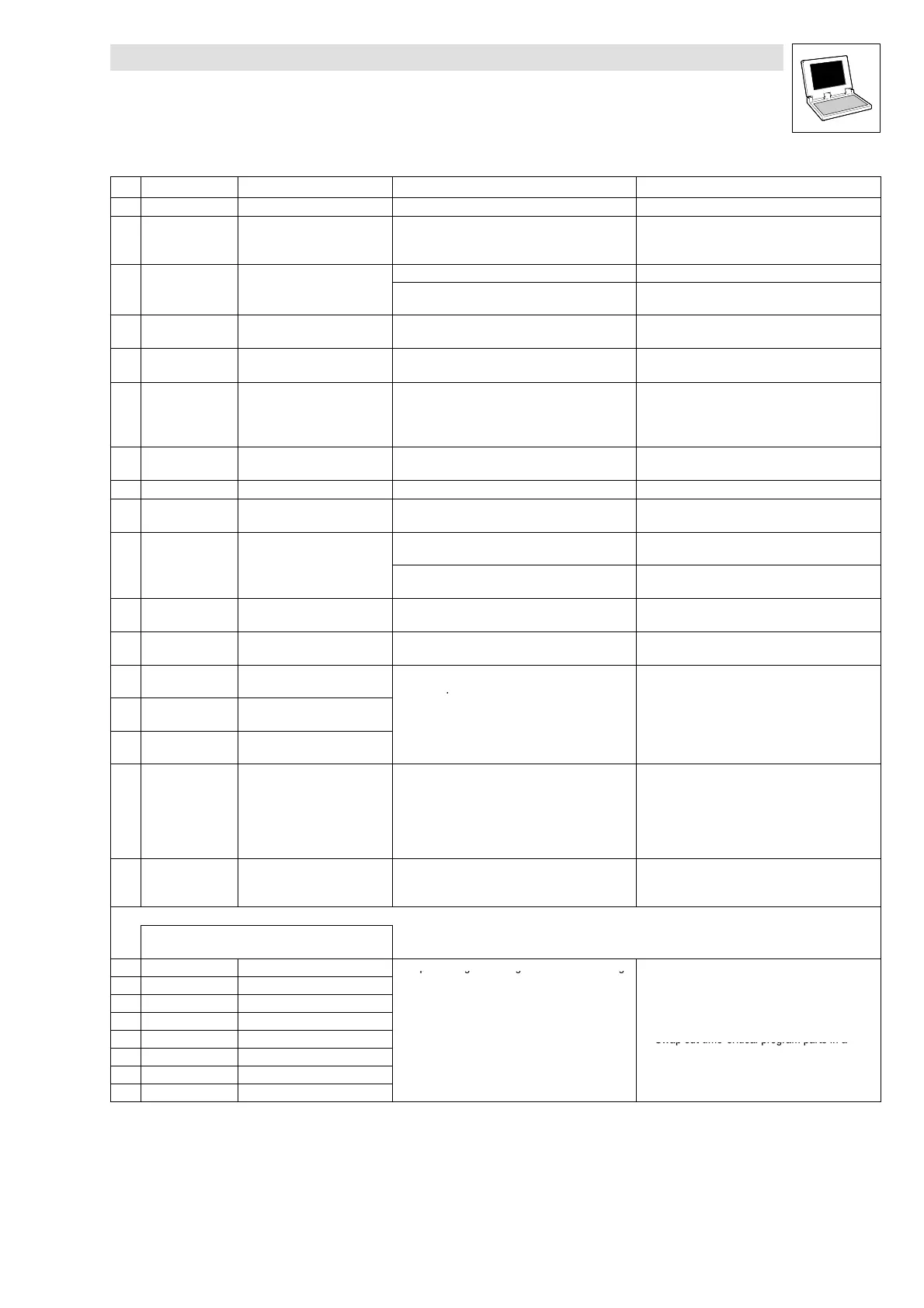

No. RemedyCauseMeaningDisplay

080 PR6 Too many user codes Reduce the number of user codes

082 SD2 Resolver fault Resolver cable interferred • Check resolver cable for open circuit

• Check resolver

• Switch off monitoring (C0586 = 3)

083 SD3 Encoder fault at X9 PIN 8

Cable interferred Check cable for open c ircuit

Input X9 PIN 8 not assigned Assign input X9 PIN 8 with 5V or switch off moni-

toring (C0587 = 3)

085 SD5 Encoder error a t X6 PIN 1 and

2 (C0034 = 1)

MastercurrentvalueatX6PIN1and2<2mA • Check cable for open circuit

• Check master current source

086 SD6 Sensor fault: motor tempera-

ture (X7 or X8)

Encoder of the motor temperature detection at X7

ot X8 indicates undefined values

• Check supply cable for firm connection

• If necessary, switch off monitoring (C0594 = 3)

087 SD7 Absolute value encoder error at

X8

Absolute value encoder with RS485 interface does

not transmit data

• Check supply cable

• Check encoder

• Check supply voltage (C0421)

• No Stegmann encoder connected

091 EEr External monitoring activated

via DCTRL

A digital input assi gned to the TRIP-Set function

has been activated.

Check external encoder

105 H05 Internal error (memory) Contact Lenze

107 H07 Internal error (power stage) During initialization of the controller, an incorrect

power stage was detected

Contact Lenze

108 H08 Extension board error

Extension board not connected correctly • Extension board connected correctly

• Connection plug EB óCheck PLC

Extension board is not supported by PLC program • Adapt PLC program to extension board

• Use extension board which is supported by PLC

110 H10 Sensor fault

Heat sink temperature

Sensor for heat sink temperature detection indica-

tes indefinite values

Contact Lenze

111 H11 Sensor fault

Inside tempera ture

Sensor for inside temperature detection indicates

indefinite values

Contact Lenze

122 CE11 Communication error

FIF-CAN1_IN

FIF-CANx_IN receives faulty data or communica-

tion interrupted

• Check cable

• Check transmitter

123 CE12 Communication error

FIF-CAN2_IN

• If possible, increase monitoring time under

C2457/x

124 CE13 Communication error

FIF-CAN3_IN

125 CE14 FIF-CAN BUS-OFF status

(too many faulty telegrams re-

ceived)

PLC has received too man y faulty telegrams send

via system bus and has disconnected itself from

the bus

• Check wiring

• Check bus termination (if any)

• Check screen contact of the cables

• Check PE connection

• Check bus load

• Reduce baud rate (observe cable length)

200 N

MAX

Maximum speed exceeded

(C0596)

• Active load (e.g. for hoists) too high

• Drive is not speed-controlled, torque

excessively limited

• Check drive dimensioning

• If necessary, increase torque limit

Time limit exceeded

(see task configuration):

201 oveR-RUN TASK1 Task mit der Id.2

Task processing takes longer than the monitoring

• Set task run-time

202 oveR-RUN TASK2 Task with Id.3

time set

• If necessary, change monitoring time

203 oveR-RUN TASK3 Task with Id.4

• Find out why the time has been exceeded by

-

204 oveR-RUN TASK4 Task with Id.5

c

ec

ng

e

as

-run

mes a

e

as

moni

or

205 oveR-RUN TASK5 Task with Id.6

• Swap out time-critical program parts in a

206 oveR-RUN TASK6 Task with Id.7

slower task

207 oveR-RUN TASK7 Task with Id.8

208 oveR-RUN TASK8 Task with Id.9

efesotomasyon.com - Lenze

Loading...

Loading...