Diagnostics and troubleshooting

Leuze electronic BPS 307i 73

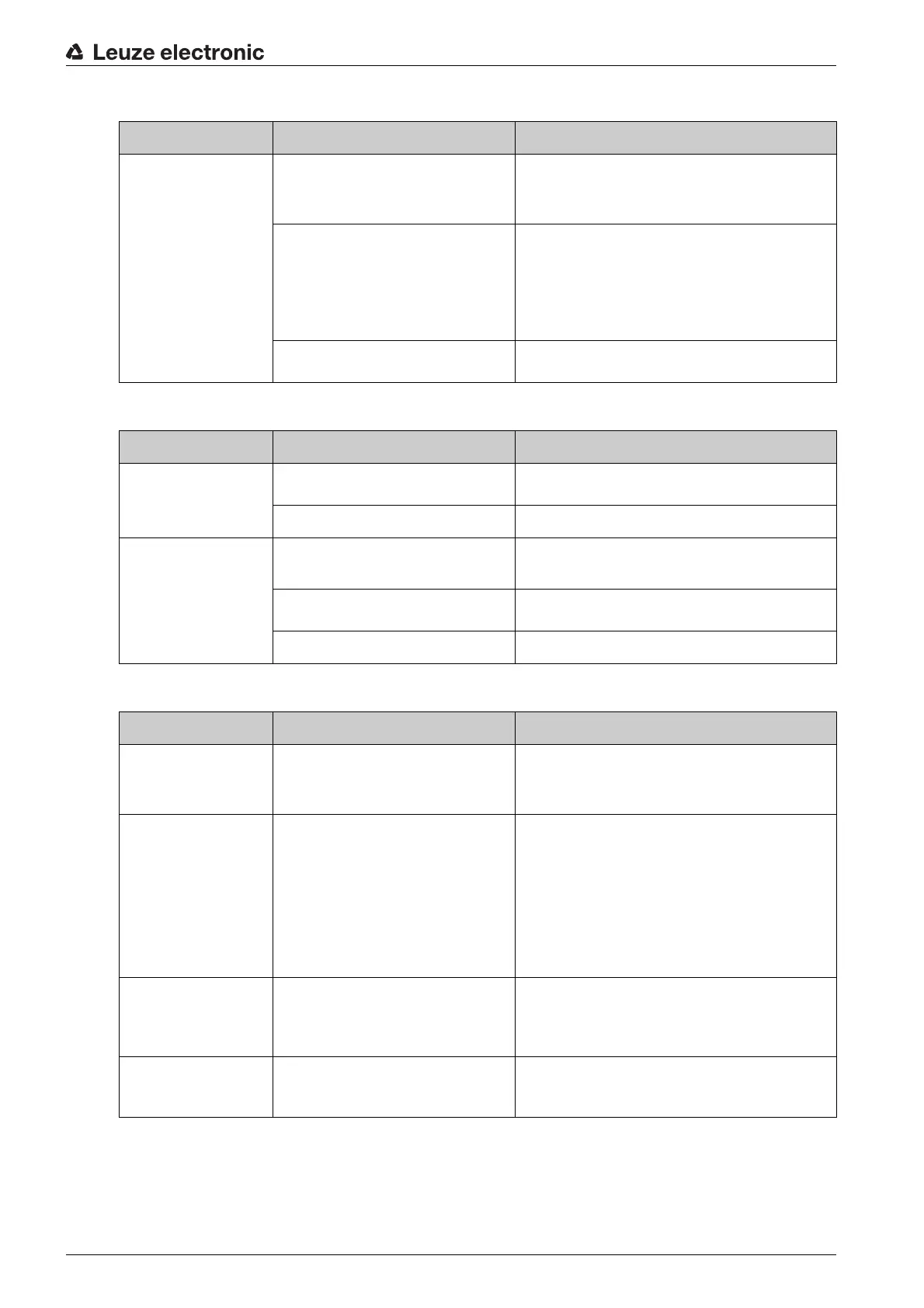

Table 10.3: Process interface errors – causes and measures

Table 10.4: LED indicators - interface errors – causes and measures

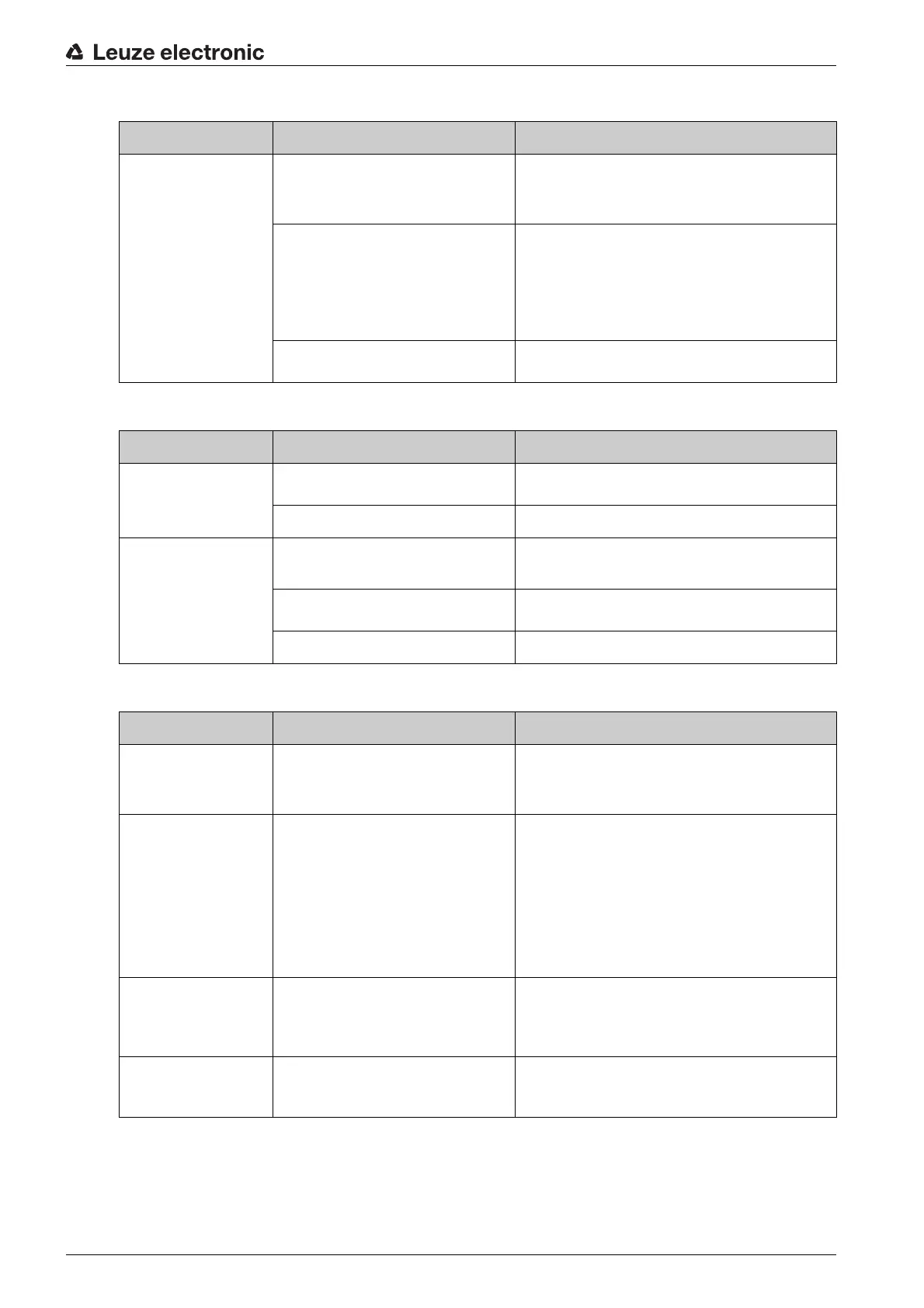

Table 10.5: Position measurement errors – causes and measures

Error Possible cause Measures

Sporadic interface

error

• Check wiring for proper con-

tacting

Check wiring:

• Check wire shielding

• Check wires used

• EMC coupling • Observe contact quality of screwed or

soldered contacts in the wiring

• Avoid EMC coupling caused by power

cables laid parallel to device lines

• Separate laying of power and data com-

munications cables

• Maximum cable length

exceeded

• Check cable lengths according to the

data rate

Error Possible cause Measures

BUS LED “Off”

• No supply voltage connected

to the device

• Check supply voltage

• Hardware error • Send device to customer service

BUS LED “red

flashing”

• Incorrect wiring • Check wiring

• Communication error • Check SSI parameters

• Carry out a reset on the control

• Different protocol settings • Check protocol settings

Error Possible cause Measures

Measurement value

or reading quality is

continuously instable

• Soiling of the BPS optics • Clean the optics of the BPS

Measurement value

or reading quality is

poor

• at certain posi-

tion values

• always at the

same position

values

• Soiling of the bar code tape • Clean the bar code tape

• Replace the bar code tape

No measurement

value can be deter-

mined

• No code in scanning beam

• Code not in the working range

of the BPS

• Align the scanning beam with the

bar code tape

• Align the BPS with the bar code tape

(working range 50 mm … 170 mm)

Faulty measure-

ment value

• Wrong bar code tape

BCB grid different from BPS

configuration

• Change BPS configuration to the

bar code tape that is being used

Loading...

Loading...