6 Instructions for Use of Pump Head

6.1 Description and Preparation

6.1.1 Description

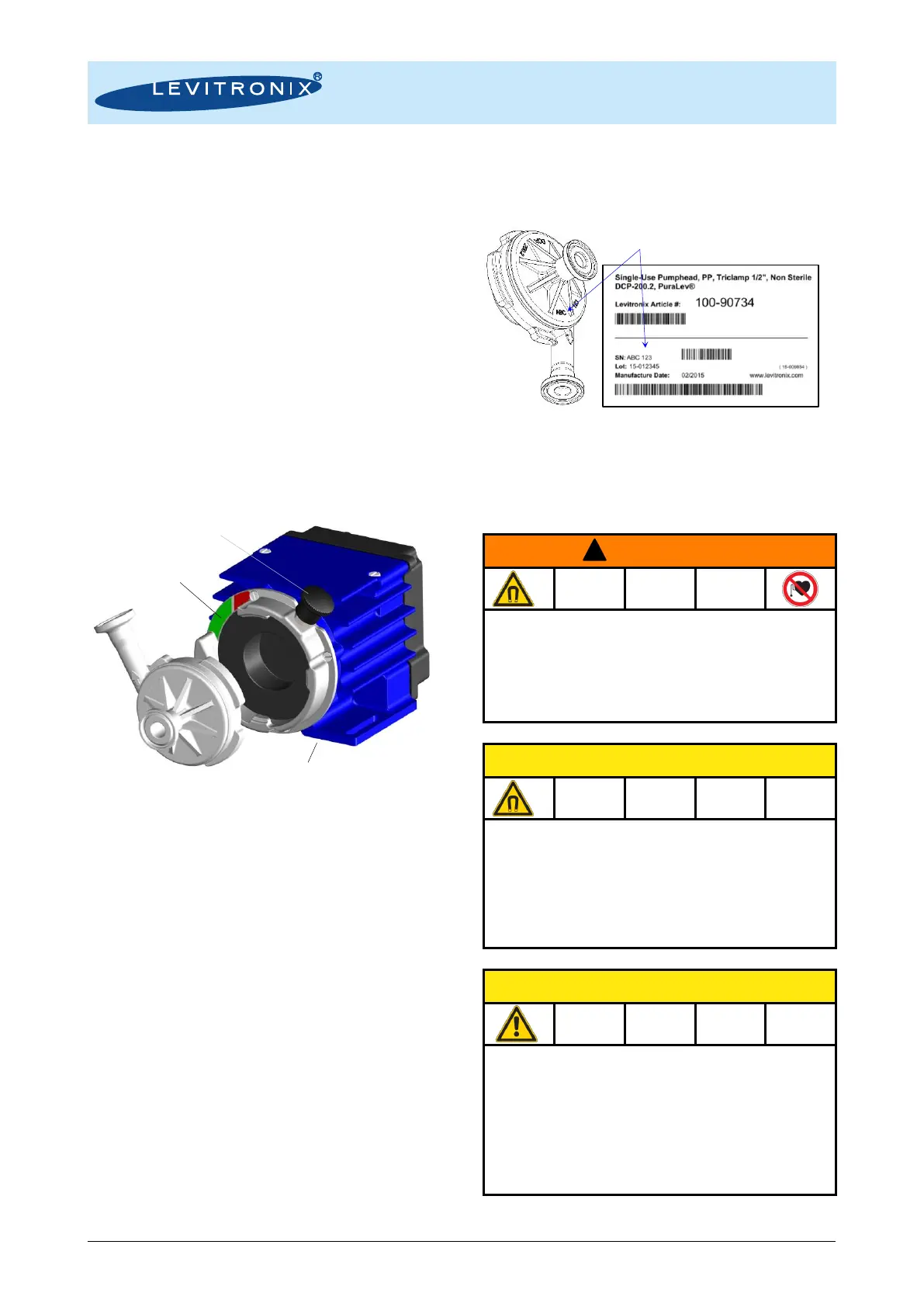

The DCP-200 pump heads are designed for single

use applications in the Life Science industries in

connection with the PuraLev

®

iF100SU flow control

system components. The wetted parts are made of

biocompatible materials (FDA, USP VI, Animal-

Free), which can be gamma sterilized.

The Pump Head is mounted to the MagLev Driver

(integrated motor and controller) via the Pump

Head Socket. The motor is connected to a

controller generating the currents for rotation and

the levitation of the impeller.

Figure 32: Single-use pump head concept

Before using the DCP-200 pump head make

yourself familiar with the following warnings,

cautions and instructions.

6.1.2 Inspection Prior to Use

The pump head should be inspected prior to use

for any damage. Do not use the pump head if any

damage is found. Contact Levitronix

®

regarding

return of any suspected pump head.

6.1.3 Traceability

For full traceability of the pump head the 6 digit

serial number located on the top of the pump head

shall be used. On the labels of the packaging and

on the biocompatibility declaration this serial

number is the one on the lid (see Figure 33).

Figure 33: Serial number for traceability of pump head

(left: on pump head, right: on label of package and the biocompatibility declaration)

6.2 General Warnings and Cautions

High Magnetic Field Strength of Impeller.

The pump head contains a rotor magnet with high

field strength. Pacemaker may be influenced, and

magnetic forces may lead to contusions. Keep

distance to pacemakers and handle pump heads with

care.

Magnetic Forces

Pay attention to the magnetic forces when handling

the pump head. It must be avoided that magnetic

parts are attracted resulting in contamination or da-

mage (for example cracks) of the housing or impeller.

Specifically pay attention to the magnetic forces,

when handling two pump heads at the same time.

Gamma Sterilization

The pump heads DCP-200 have been tested to be

robust against gamma radiation with a dose up to

40 kGy.

Handle the pump heads with care, especially after

gamma radiation with doses above 25 kGy, since the

radiation exposure decreases the flexibility of the

pump head material.

Loading...

Loading...