19

Tip: If the board does not follow the fences, the cause may be

that the back fence is not on the right level with the cutter, that

the fences are not parallel to each other, or that the fences are

not positioned straight in the machine. If you have difculties in

getting the fences positioned straight in the machine, it is better

that they are angled slightly to the left, in the direction of cutter

3. Then the feed rollers will press the work piece up against the

fences. If the fences are angled slightly to the right, away from

cutter 3, the feed rollers will pull the work piece away from the

fences, which will lead to incorrect measurements and a planed

surface that is below par.

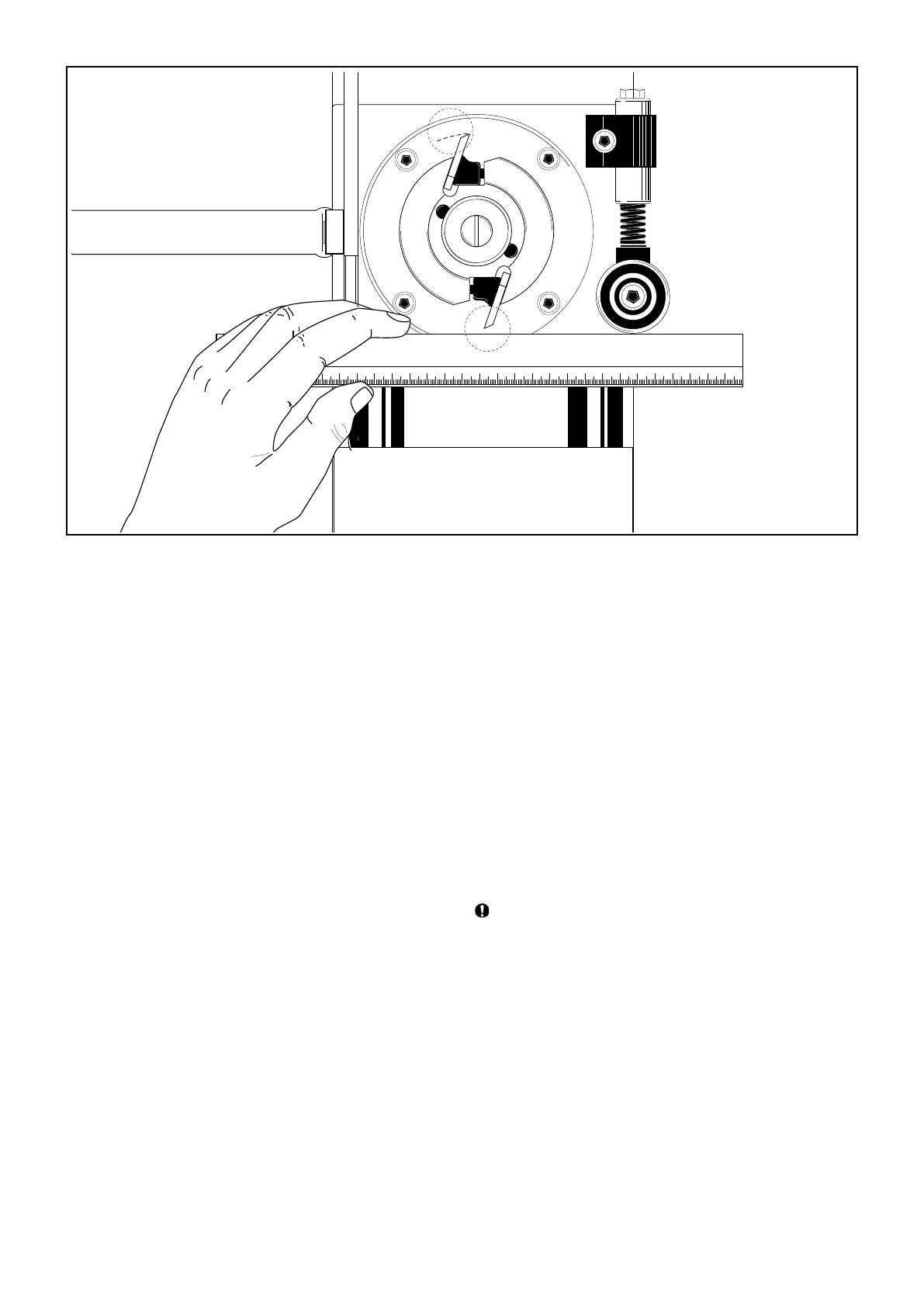

Adjusting cutter 3 (the movable cutter)

Loosen the locking handle (21), which is located on the carriage

under the machine table. Using the crank (42) at the side of

the machine, move the cutter in or out to the desired planing

width. One turn on the crank represents 4 mm (ca. 0.2”). Using

a vernier calliper, measure the distance between the cutter and

the back fence. This measurement represents the width of the

processed board. Fix the cutter in this position by tightening the

locking handle under the machine table.

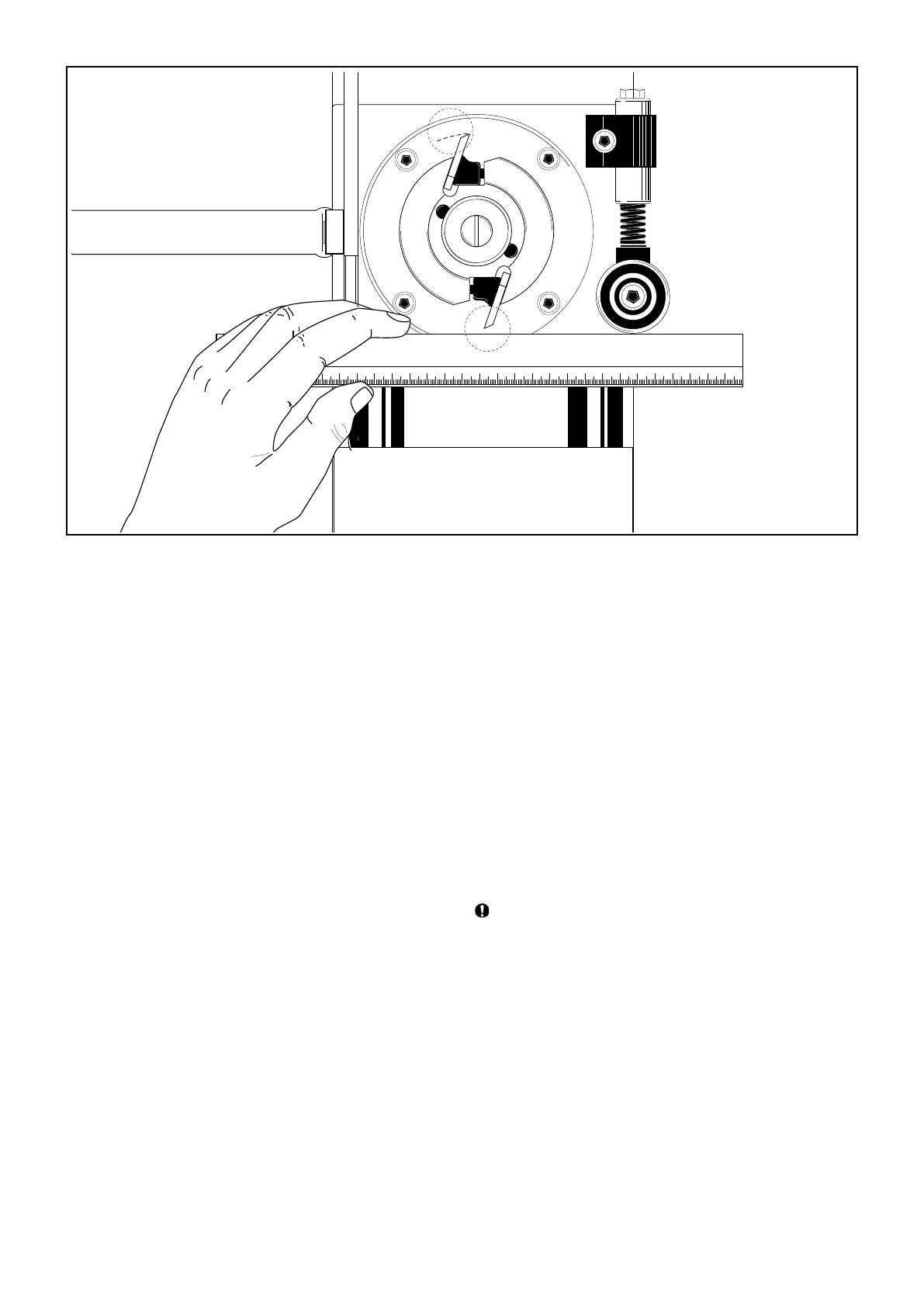

Setting the pressure rollers and the chip deector at the

movable cutter

In front of the movable cutter there are two pressure rollers

(68), which press the work piece up against the fences. By

adjusting these you determine how wide a work piece the

machine can be fed with. These pressure rollers are mounted

on an aluminium L bracket (64) that is attached to the movable

cutter’s carriage, which makes them move with the cutter when

it is being adjusted.

To set the pressure rollers, you loosen the Allen screw (using

a 6 mm Allen key) that secures the L bracket on the carriage

of the movable cutter. Adjust the L bracket so that the pressure

rollers are pressed in approx. 5 mm when the work piece is fed

into the machine.

In front of the movable cutter you can mount a chip deector

(supplied) between the L bracket and its vertical screw plate.

The chip deector has oval holes, which enable the deector

to be moved in or out from the work piece. The chip deector

serves as a chip guide, but also as a fence in front of the cutter,

which lowers the risk of long splinters being produced from the

work piece, when the cutter takes off a lot of wood.

Adjust the chip deector so that it will be pressed in a couple

of millimetres by the part of the work piece that is not yet

processed.

When you are processing boards of various widths, make

sure that the chip deector does not run the risk of being

pressed in so much that it comes in contact with the cutter

knives. When the deector is pressed in, there should be a

safety margin of at least one centimetre (0.4”) between the

deector and the cutter knives.

Behind the movable cutter there is an additional pressure

roller (46), which presses the work piece up against the back

fence. Set this pressure roller so that it extends approx. 1-3 mm

(0.04-0.1”) past the cutter’s innermost cutting diameter at the

level of the pressure roller.

Loading...

Loading...