3-2 Issue 4 February 1997

363-208-011

Cabling, Wiring, and Assembly

f. Discrete alarm connections for environment status and controls.

g. Power connections from the -48 volt battery plant.

h. Ringing connections from the customer’s positive and/or negative ringing

supplies.

i. Synchronization inputs from the office clocks supplies.

j. Operational System (OS) inputs from remote maintenance centers.

These external cables must be engineered for the complete installation of the

SLC

-2000 COT Frame.

NOTE:

All cables are not required for each installation. See Notes 201 and 202 on

Sheet D1 of SD7C180-01 for information about the orderable customer

interface cables for central office applications. Refer to the engineering

specifications for a particular office application.

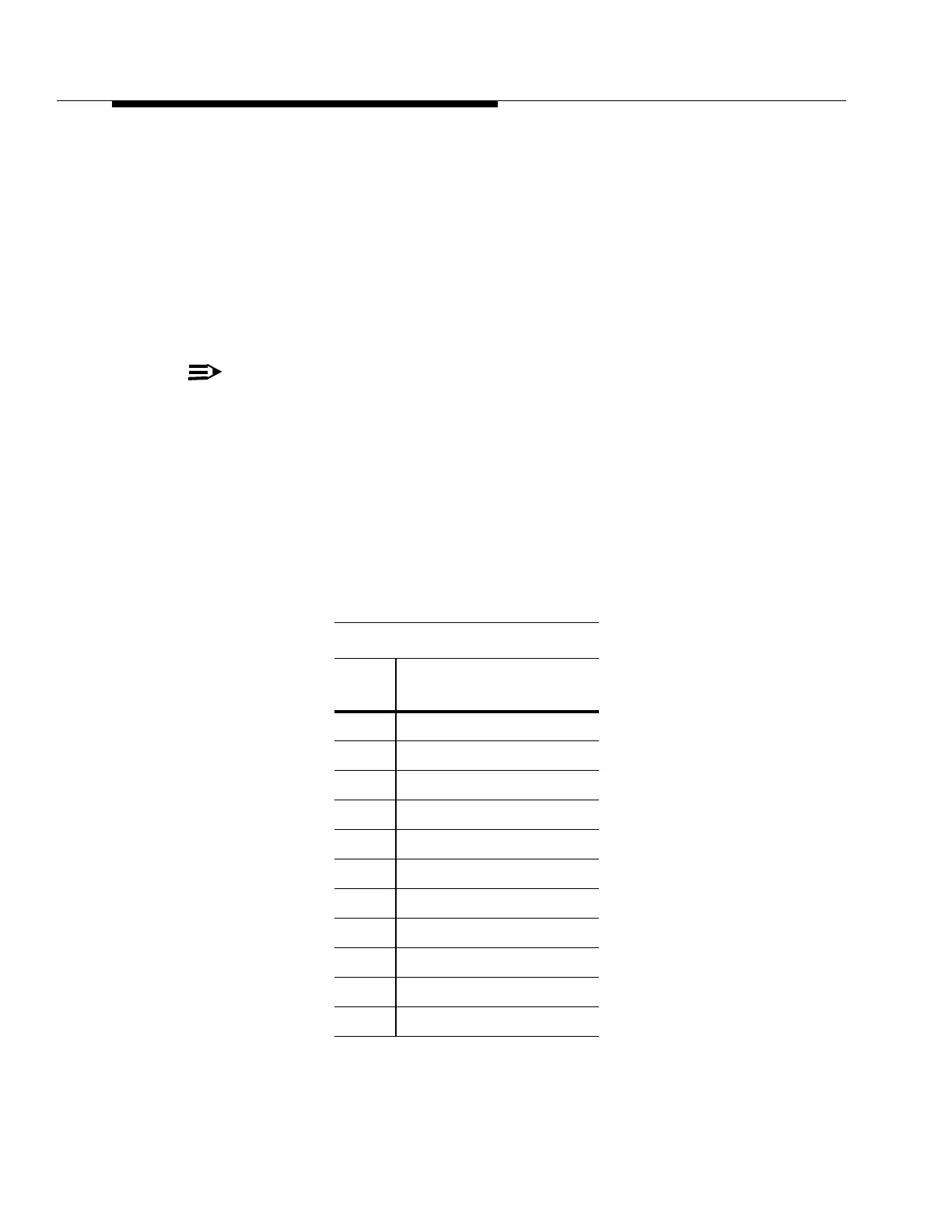

Factory Cable Assembly Wire Color Coding Sequence

Standard wire color coding for the factory assembled cables is shown in the

following table. This coding sequence is followed on VF, DS1 and other cables

used as danglers and as Customer Interface connections. Use of the color coding

will facilitate both terminating operations at the customer’s cross-connecting

points and troubleshooting routines.

Conductor Identification

Pair

No.

Colors

(Tip/Ring)

1 white-blue/blue-white

2 white-orange/orange-white

3 white-green/green-white

4 white-brown/brown-white

5 white-slate/slate-white

6 red-blue/blue-red

7 red-orange/orange-red

8 red-green/green-red

9 red-brown/brown-red

10 red-slate/slate-red

11 black-blue/blue-black

Loading...

Loading...