V−belts

131

V−belts

Checking condition

D Check V−belts for cracks, oil, overheating and

wear

D Change demaged V−belts

If, in the case of a multiple belt drive , wear or

differing tensions are found, always replace the

complete set of belts.

Checking tension

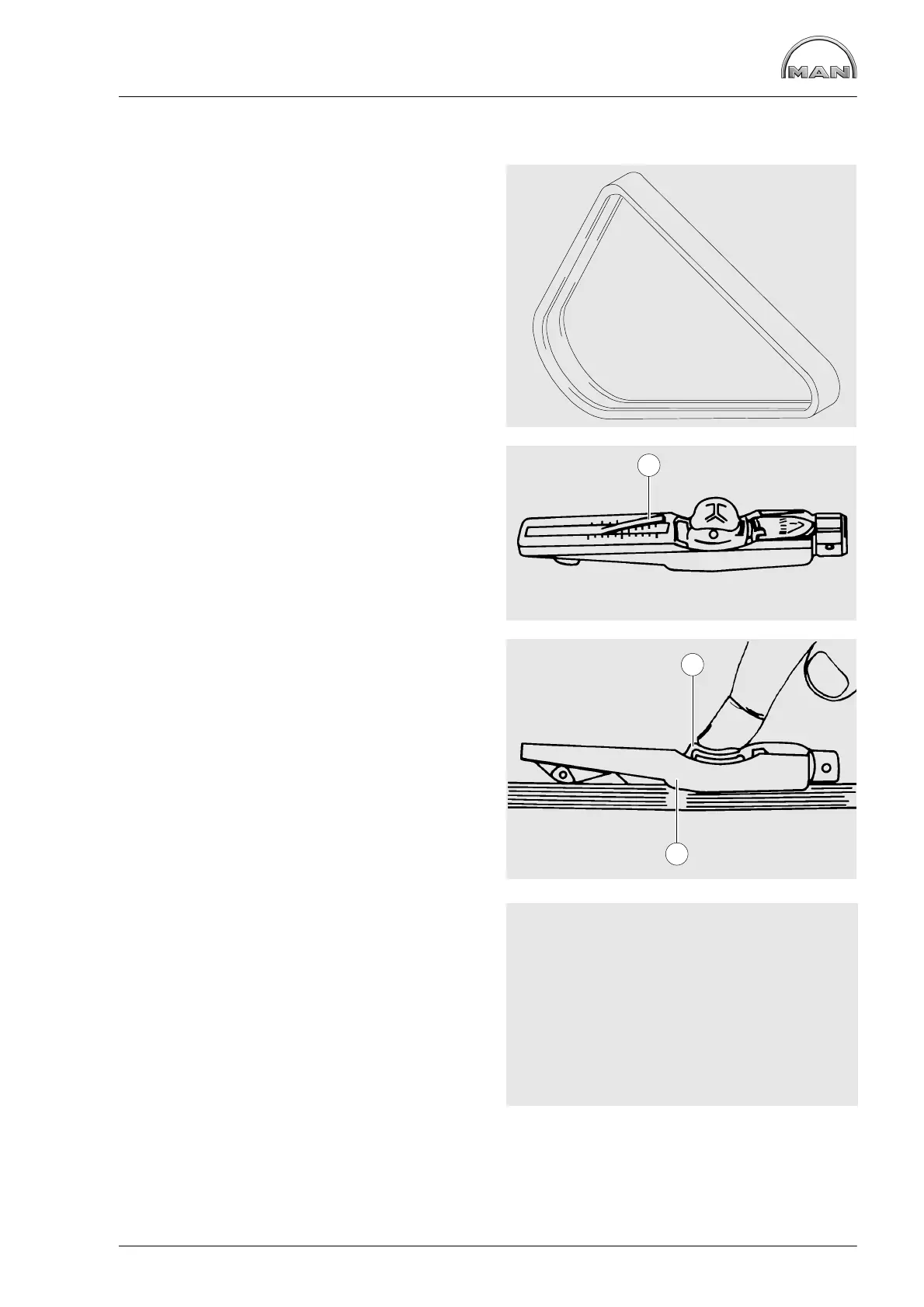

Use V−belt tension tester to check V−belt tension.

D Lower indicator arm À into the scale

D Apply tester to belt at a point midway between

two pulleys so that edge of contact surface Á is

flush with the V−belt

D Slowly depress pad  until the spring can be

heard to disengage. This will cause the indica-

tor to move upwards

If pressure is maintained after the spring has dis-

engaged a false reading will be obtained!

Reading of tension

D Read of the tensioning force of the belt at the

point where the top surface of the indicator arm

À intersects with the scale

D Before taking readings make ensure that the

indicator arm remains in its position

If the value measured deviates from the setting

value specified, the V−belt tension must be cor-

rected.

1

2

3

Drive

Tensioning forces according to

the kg graduation on the te-

ster

belt

New installation

When ser-

width

Installation

After 10

min. run-

ning time

vicing after

long run-

ning time

2/3VX 90−100 70−80 60

Loading...

Loading...