3-15

Published 3/26/2018, Control # 596-05

GRT8100 SERVICE MANUAL ELECTRICAL SYSTEM

Installation

1. Inspect belt. Verify it has no cracks or other damage.

Replace damaged belt as needed.

2. Install alternator using mounting bolts and washers.

Torque bolts; refer to Fasteners and Torque Values,

page 1-15 for the proper torque value.

3. Install belt on all engine pulleys except alternator pulley.

4. Turn tensioner clockwise. Slip belt on alternator pulley,

then carefully return t tensioner to its normal position.

Make sure belt is centered on tensioner.

5. Check belt tension at center of longest distance between

pulleys. Push in on belt with your thumb. Belt should

deflect no more than 3/8 in - 1/2 in (10 mm - 13 mm). Or,

using a belt tension gauge, verify 60 lb - 130 lb (267 N -

578 N) tension Replace belt if it is too loose

(overstretched).

6. Verify tensioner bolt is torqued to 32 lb-ft (43 Nm).

7. Connect electrical leads to terminals as tagged during

removal.

8. Close engine compartment.

9. Reconnect ground cables to the battery.

10. Install ECM power fuse.

11. Turn battery disconnect switch to ON position.

Check

1. Run engine. Verify reading of voltmeter on front console

is 24 volts or greater. Make repairs as needed.

2. Continue troubleshooting charging system as needed if

replacement of alternator did not correct problem in

charging system.

Starter Replacement

Removal

1. Ensure key switch has been in the OFF position for 2

minutes.

2. Turn battery disconnect switch to OFF position.

3. Remove ECM power fuse.

4. Remove negative battery cables.

5. Open engine compartment.

6. Tag and disconnect electrical leads from starter

terminals.

7. Remove bolts holding starter to mounting pad. Remove

starter.

Installation

1. Place starter on mounting pad. Secure starter with bolts.

Torque to 32 lb-ft (43 Nm).

2. Connect electrical leads to terminals as tagged during

removal.

3. Reconnect the ground cables to battery.

4. Install ECM power fuse.

5. Turn the battery disconnect switch to the ON position.

Check

1. Try to start engine. Verify starter engages engine.

2. Start engine again and listen for starter noises. Verify

there is no abnormal noise indicating starter gear is

meshing properly with flywheel, gear hasn’t remained

engaged to the flywheel after the ignition switch is in the

ignition (run) position, or some other problem. Install

starter properly as needed.

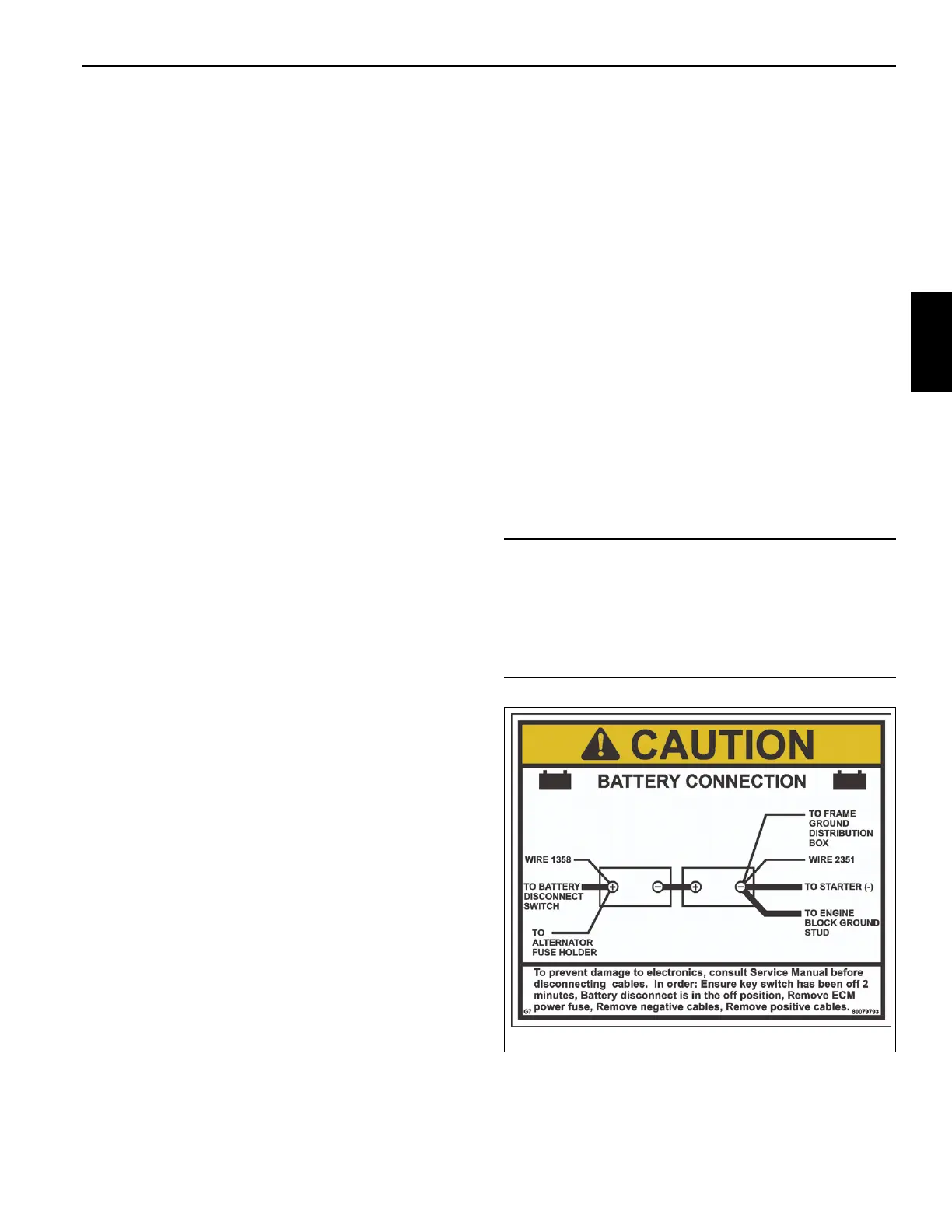

Battery Replacement

Removal

CAUTION

To avoid possible engine fault codes and undesirable

operation, ensure keyswitch has been off 2 minutes

before disconnecting batteries.

Disconnect batteries if machine will be inactive for over

24 hours.

Loading...

Loading...