ELECTRICAL SYSTEM GRT8100 SERVICE MANUAL

3-14

Published 3/26/2018, Control # 596-05

Alternator/Charging System

Troubleshooting

Test batteries, alternator, and cables any time there is a

problem with the charging system.

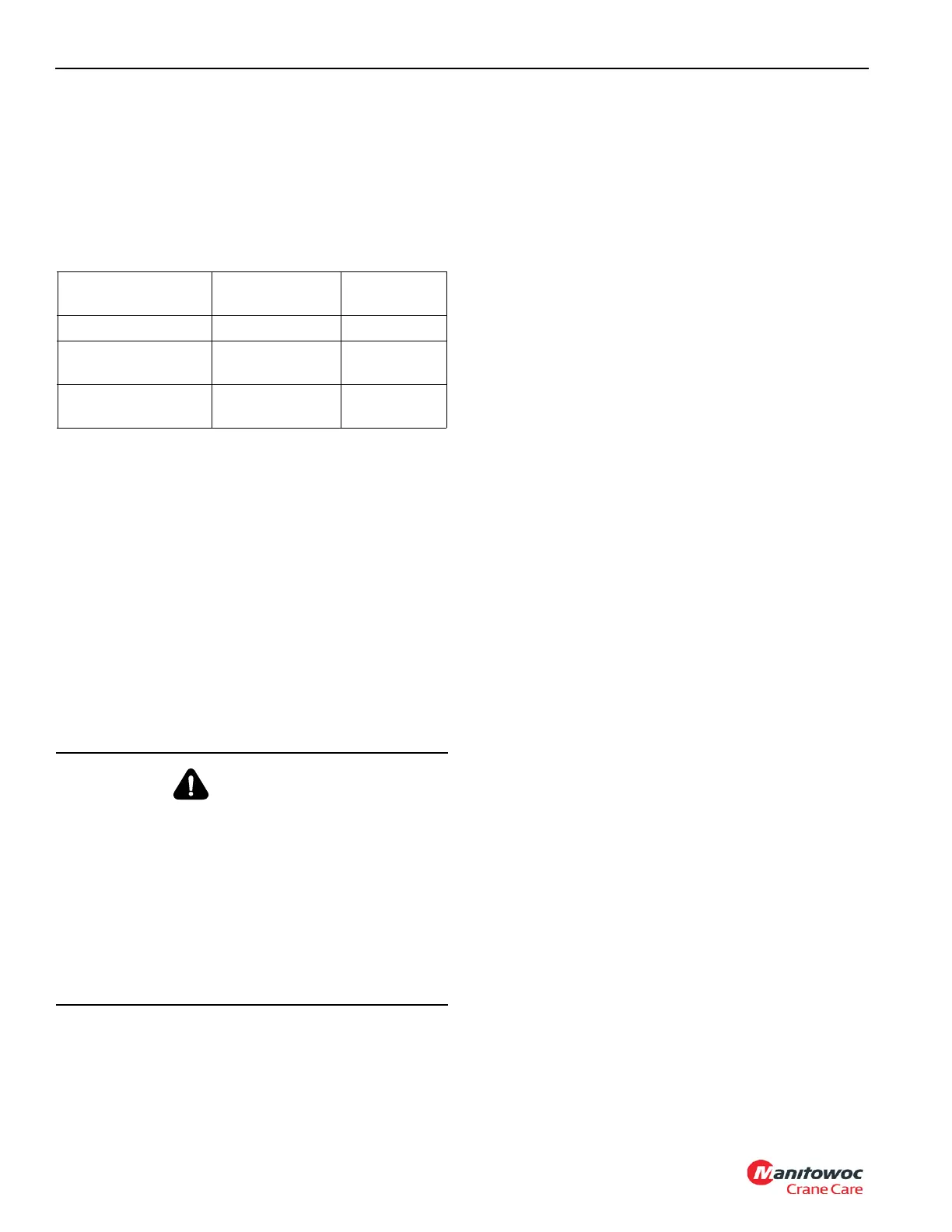

Required Tools

The following tools are required to diagnose the charging

system:

Visual Check

• Belts: tight, in good condition, not frayed, cracked or

glazed.

• Pulley: tight, aligned with other pulleys, not glazed.

• Alternator mounting bolts and wiring connections: clean

and tight, no signs of heat damage.

• Batteries: terminals and cables, clean and tight, no

corrosion or signs of heat damage.

• Check alternator fuse if Alternator Charge Lamp is

illuminated on the steering column display while engine

is running.

Engine Off Tests

Batteries

Disconnect batteries and test each battery individually.

Check electrolyte level if possible.

Using a multimeter, measure voltage across terminals. If

should read 130 A to 135 A.

NOTE: If correct readings were not obtained in the Engine

On Tests, perform the following two tests.

Voltage Drop Test

Positive Side

1. Set multimeter to the 2 volt range.

2. Connect positive (

+) lead to alternator output terminal

and negative (

–) lead to battery positive terminal or post.

Do not connect meter to battery cable.

3. Run engine at 2000 rpm.

4. Load system with carbon pile load or lights and heater

blower.

Allowable drop is 0.2 to 0.5 volts. Higher voltage drop

indicates loose, corroded, or broken connections.

Negative Side

1. Set multimeter to 2 volt range.

2. Connect negative (

–) lead to alternator case and positive

(

+) lead to battery negative terminal or post. Do not

connect meter to battery cable.

3. Run engine at 2000 RPM.

4. Load system with carbon pile load, or lights and heater

blower.

Allowable drop is 0.1 to 0.3 volts. Higher voltage drop

indicates loose, corroded, or broken connections. If any

voltage drop is greater than the normal range, troubleshoot

system and repair any problems.

After correcting any problems, perform Engine On Tests

again. If satisfactory results are not obtained, remove

alternator and bench test.

Replace Alternator

Removal

1. Ensure key switch has been in the OFF position for 2

minutes.

2. Turn battery disconnect switch to OFF position.

3. Remove ECM power fuse.

4. Remove negative battery cables.

5. Open engine compartment.

6. Tag and disconnect electrical leads from alternator

terminals.

7. Using a 1/2 in drive bar/ratchet, turn tensioner below the

alternator clockwise to remove belt tension. Slip belt off

alternator pulley. Let tensioner return to its normal

position.

8. Remove alternator mounting capscrews and alternator.

Equipment Example

Manitowoc

Part No.

Digital Multimeter Fluke

® 177 9999101763

Carbon Pile Load

Tes te r

Autometer

® SB5 9999101765

Current Clamp

Meter

Fluke

® 336 9999101764

DANGER

Do not smoke or allow sparks or open flame near

batteries, they can explode.

When working with batteries always wear protective

clothing, gloves and eye protection. Batteries contain

corrosive liquids that can burn skin and eyes and

destroy clothing.

Remove rings, watches or other jewelry before working

with batteries. A battery can produce a short-circuit

current high enough to weld a ring or similar to metal

causing severe burns

Loading...

Loading...