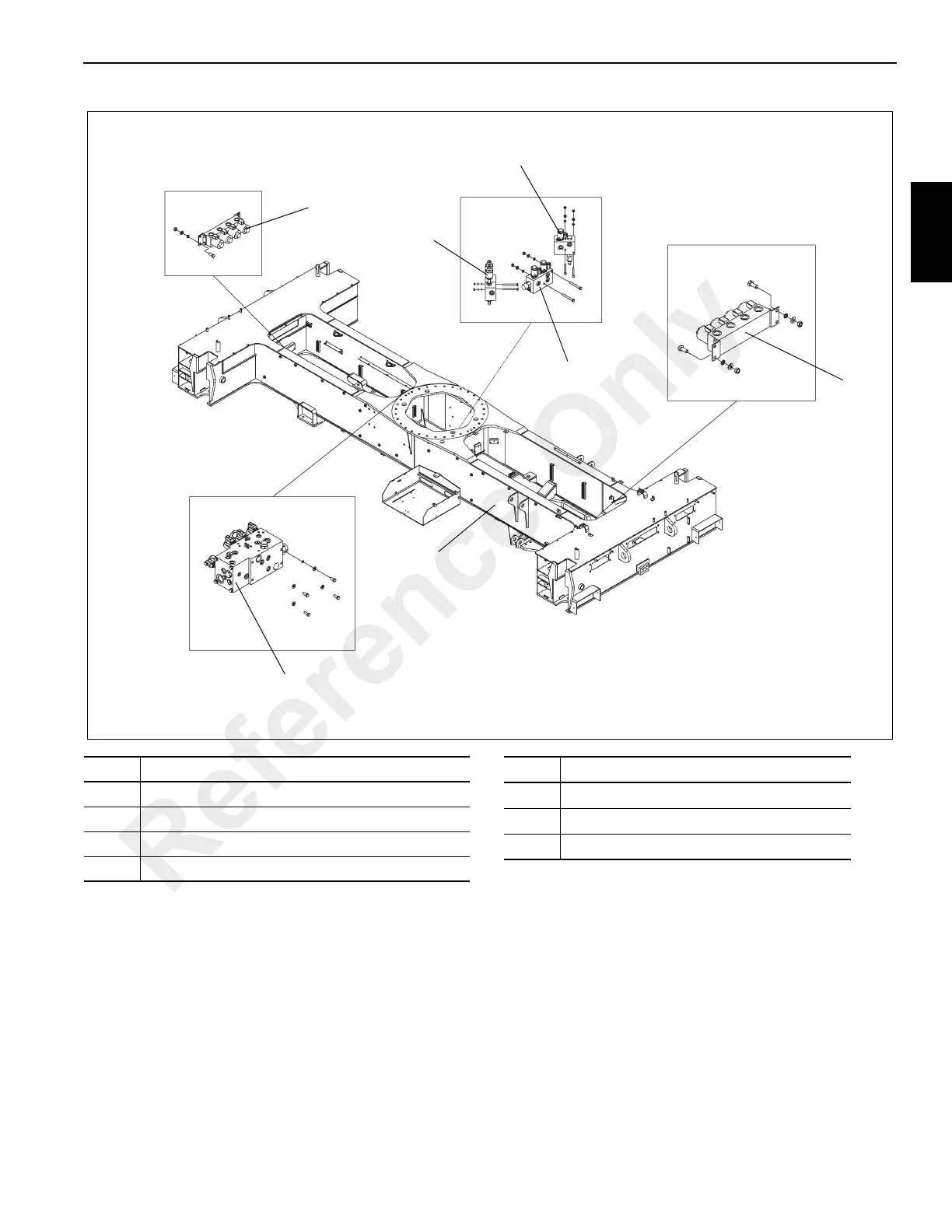

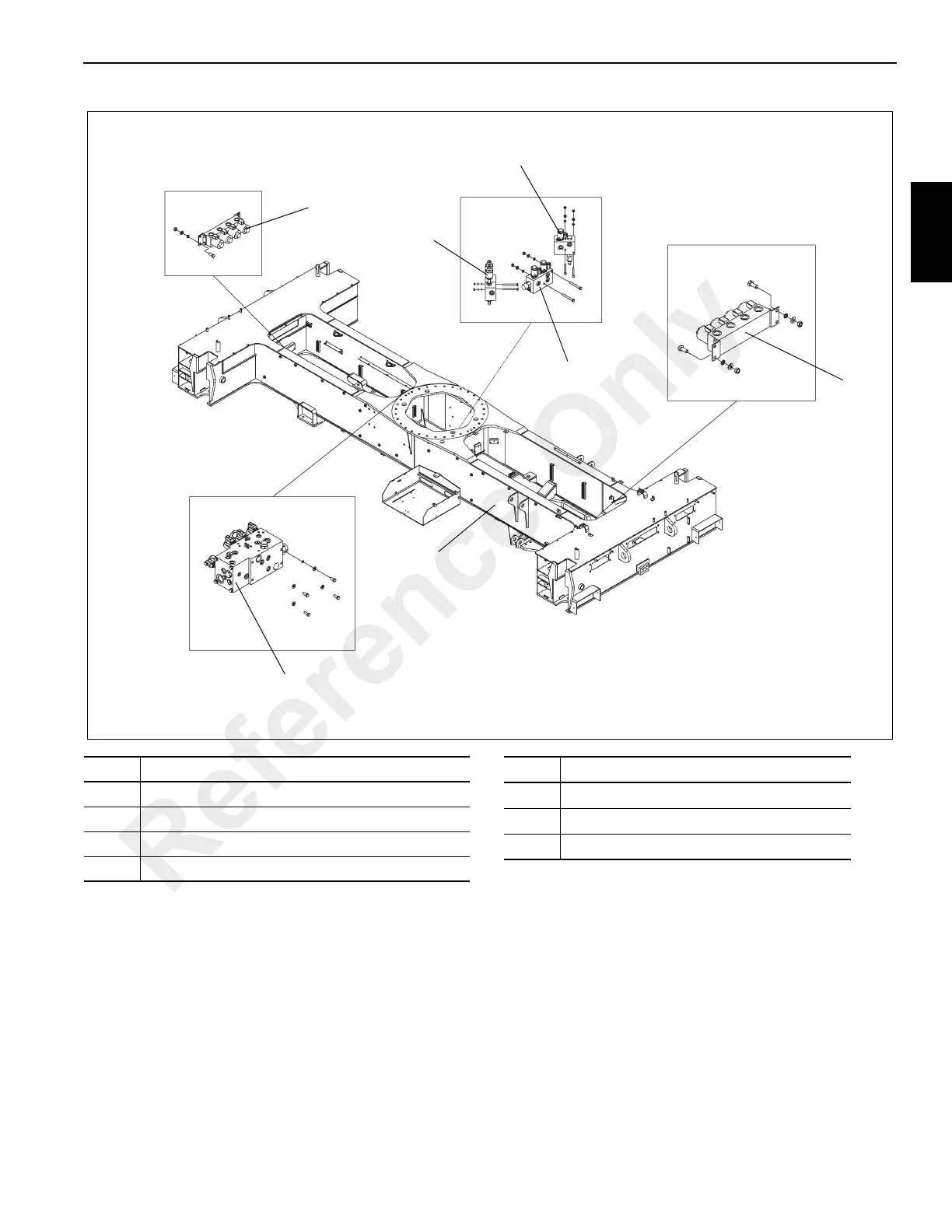

Published 4-20-2015, Control # 502-01 2-29

RT540E SERVICE MANUAL HYDRAULIC SYSTEM

2

4

5

3

1

6725

CARRIER

FIGURE 2-14 continued

6

7

Item Description

1 Front Outrigger Control Manifold

2 Outrigger/Rear Steer Valve

3 Differential Lock Valve

4 Park Brake Range Shift Valve

Item Description

5 Axle Lockout Valve

6 Rear Outrigger Control manifold

7Frame

Reference Only

Loading...

Loading...