UNDERCARRIAGE RT880E SERVICE MANUAL

8-18 Published 11-10-2014, Control # 524-00

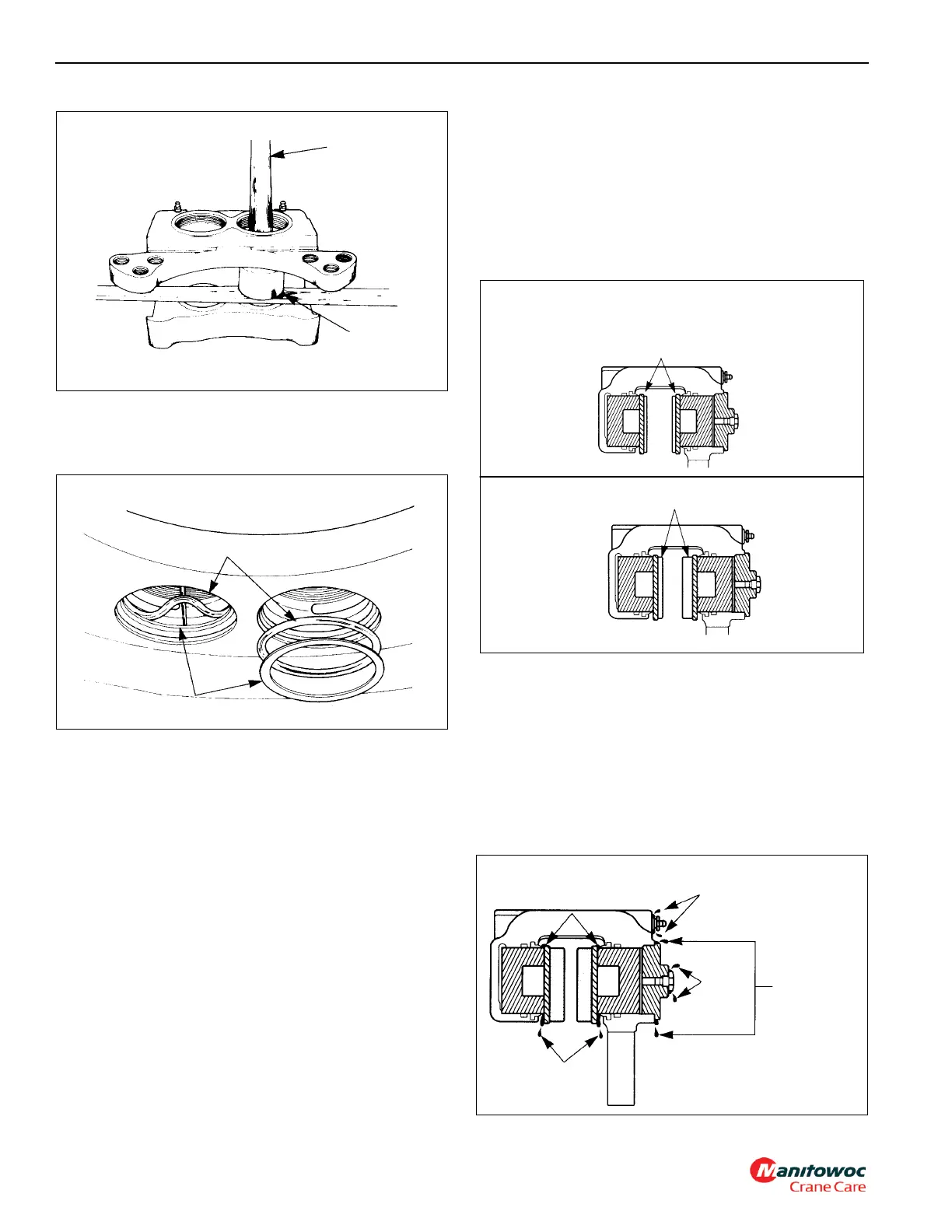

8. Remove the dust seals from the housing.

9. Remove and discard the O-ring and the backup rings

(Figure 8-18).

10. Inspect the ring grooves in the housing for scratches and

rust. Remove small scratches and rust with emery cloth.

Replace the housing if there are large scratches or large

amounts of rust. Refer to Inspection - Caliper Parts.

11. Inspect the pistons and the bores for scratches and rust.

Remove small scratches and rust with emery cloth.

Replace the components if they are worn or if there are

large scratches or large amounts of rust. Refer to Cali-

per Parts, page 8-19.

Inspection

Periodic On-Vehicle

Inspect the caliper, linings, and disc for any damage.

Shoes, Linings, and End Plates

Remove the shoes and linings. To help prevent abnormal

lining wear, replace worn, bent, or cracked end plates and

distorted backing plates. Inspect end plate bolts for wear.

Replace the bolts if worn. Inspect the linings for:

• Lining Wear. Replace the linings when the thickness

of the lining is less than 0.125 in (3.2 mm) from the

back plate (Figure 8-19).

• Lining Wear Not Even. Replace the linings if the

thickness of the two linings is significantly different.

Check the pistons for correct operation. Replace the

piston and/or housing if a piston is cocked in the

bore. Check that the disc surface is flat and parallel

to the linings (Figure 8-19).

• Oil or Grease on Linings. Replace the linings.

• Cracks on Linings. Replace linings that have large

or deep cracks.

NOTE: Small, tight cracks on the surface of the lining are

normal when the caliper is used under high temper-

ature conditions.

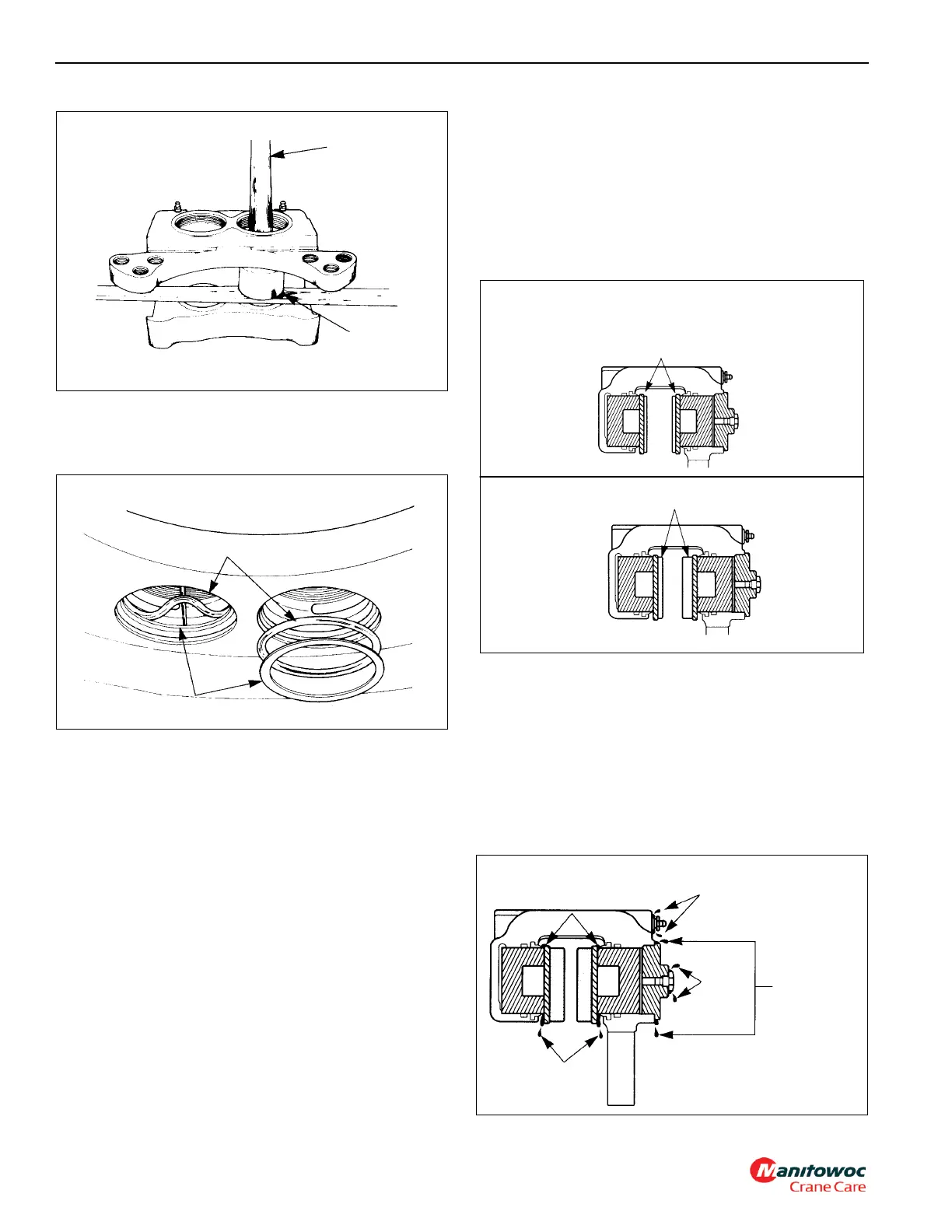

Caliper for Leaks

Inspect the following areas for fluid leaks (Figure 8-20).

Wood Block

Piston

FIGURE 8-17

O-Ring

Backup Ring

FIGURE 8-18

Minimum Lining Thickness

0.125 in (3.2 mm) from

Backing Plate

Uneven Lining Wear

FIGURE 8-19

Inlet

Fitting

Fluid

Leaks

Cylinder

Cap

Fluid

Leaks

Piston Fluid

Leaks

Bleeder Screw

Fluid Leaks

Piston Fluid

Leaks

FIGURE 8-20

Loading...

Loading...