TRANSMISSION AND TORQUE CONVERTER 5540F/YB5515 SERVICE MANUAL

7-36 Published 10-21-2010, Control# 198-04

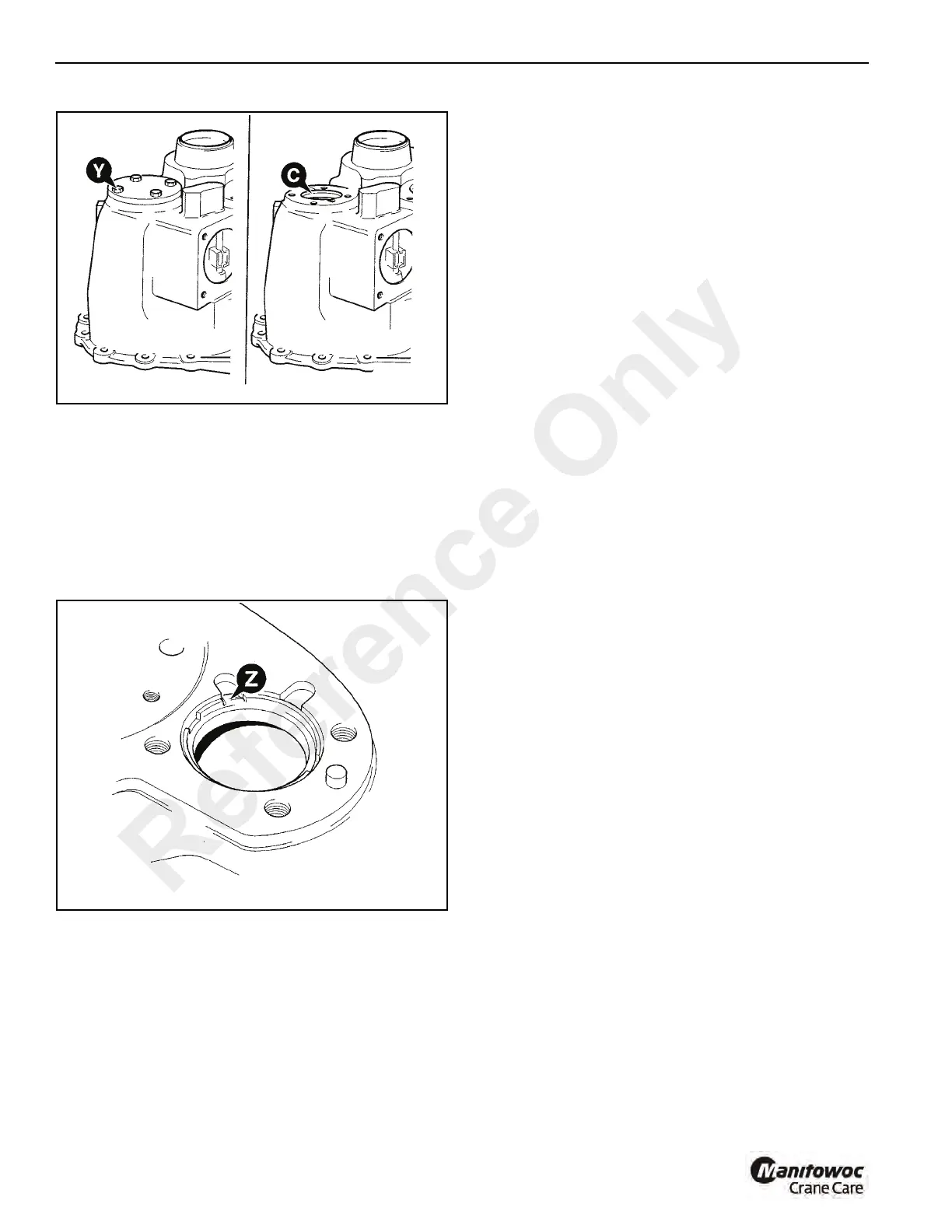

1. Carefully pry out the staked section of the ring Z

(Figure 7-37) clear of the casing.

2. Unscrew and discard the ring.

3. Be sure to remove any shards of metal that may have

fallen into the casing.

NOTE: Once removed, the setting rings must not be re-

used. Discard the ring and obtain a new one. Note

that the mainshaft and layshaft setting rings are not

interchangeable

Inspection

Before assembling the gearbox make sure that a thorough

inspection of all components is carried out. Remember that

although a failed component may be easy to identify, the

cause of that failure may be less easy to trace. It is also

possible that a failed component may have caused damage

to other areas of the gearbox.

1. Carefully remove all traces of gasket compound from

components as follows:

a. Front and rear casing mating faces.

b. Front casing and torque converter housing mating

faces.

2. Clean the inside of the casings using a suitable

degreasing agent.

3. Carefully inspect all gears, bearings and shafts for signs

of excessive wear or damage. If wear or damage is

evident, components must be renewed.

4. Make sure that all oil way cross drillings in the casings,

shafts and gears are clear and free from debris. Blocked

oil ways are a common cause of bearing failure. Use an

air line to blow through cross drillings.

NOTE: If failure of the reverser unit or hydraulic 2/4-wheel

drive unit is suspected, see the relevant

disassembly and assembly procedure in this

section.

1st/2nd Gear Synchromesh Unit

The 1st/2nd gear synchro unit must be checked for wear

before assembly as follows:(See Figure 7-38 thru

Figure 7-40)

1. Before dismantling the unit be aware that on

reassembly, the components must be kept in their

original relationships.

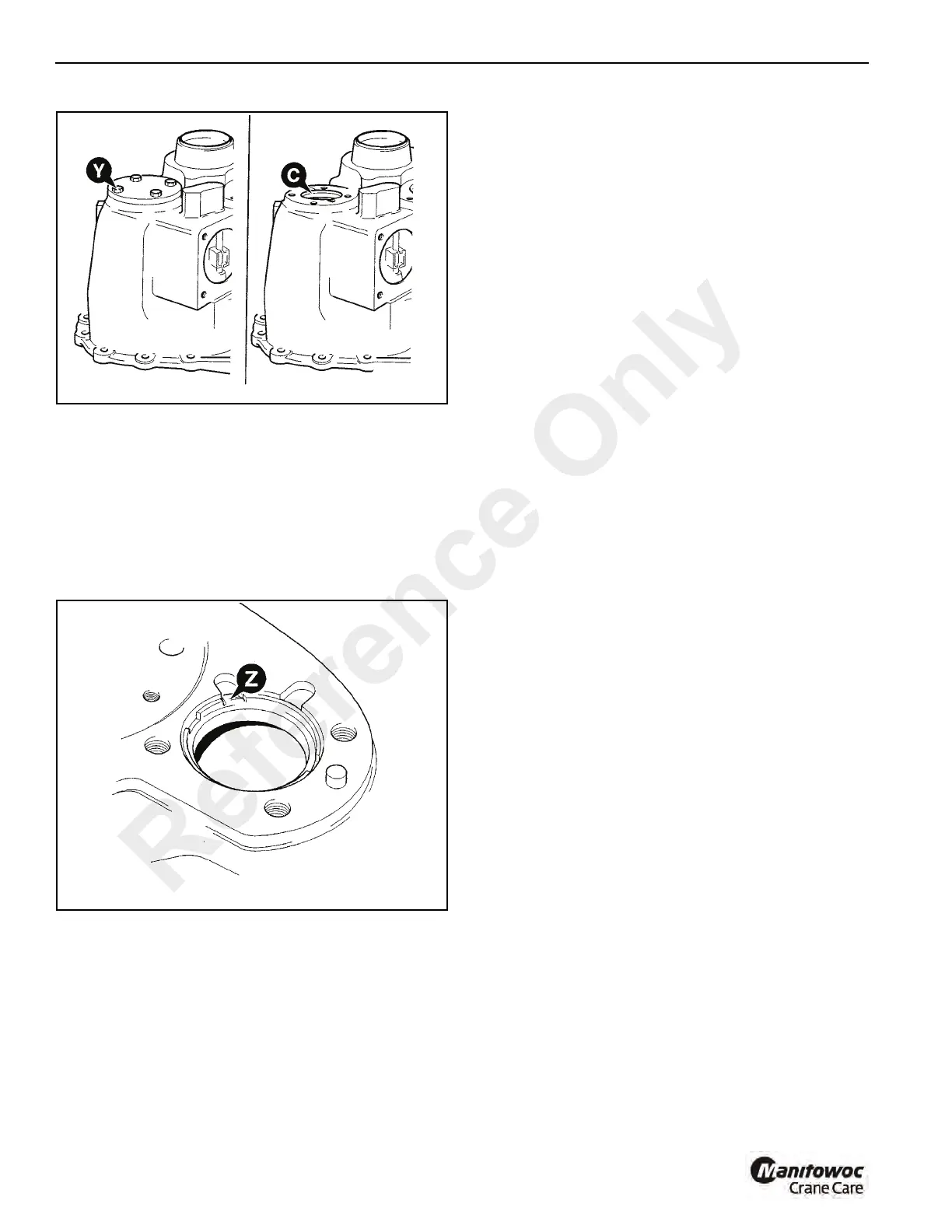

2. Disassemble the unit by removing the cones and rings

A1, A2 and B1, B2. Push off the sleeve C taking care to

retrieve the sets of balls D, poppets E and springs F.

3. Inspect the mating faces of cones and rings. The wear

indicator grooves X must still be visible. As a further

check, locate the cones and rings together (as shown at

Y) and measure the clearance between them using

feeler gauges. The clearance should be between 0.02 in

and 0.7 in for both A and B pairs. If either is out side

these limits then the complete synchro unit must be

renewed.

Reference Only

Loading...

Loading...