GROVE Published 10-21-2010, Control# 198-04 7-35

5540F/YB5515 SERVICE MANUAL TRANSMISSION AND TORQUE CONVERTER

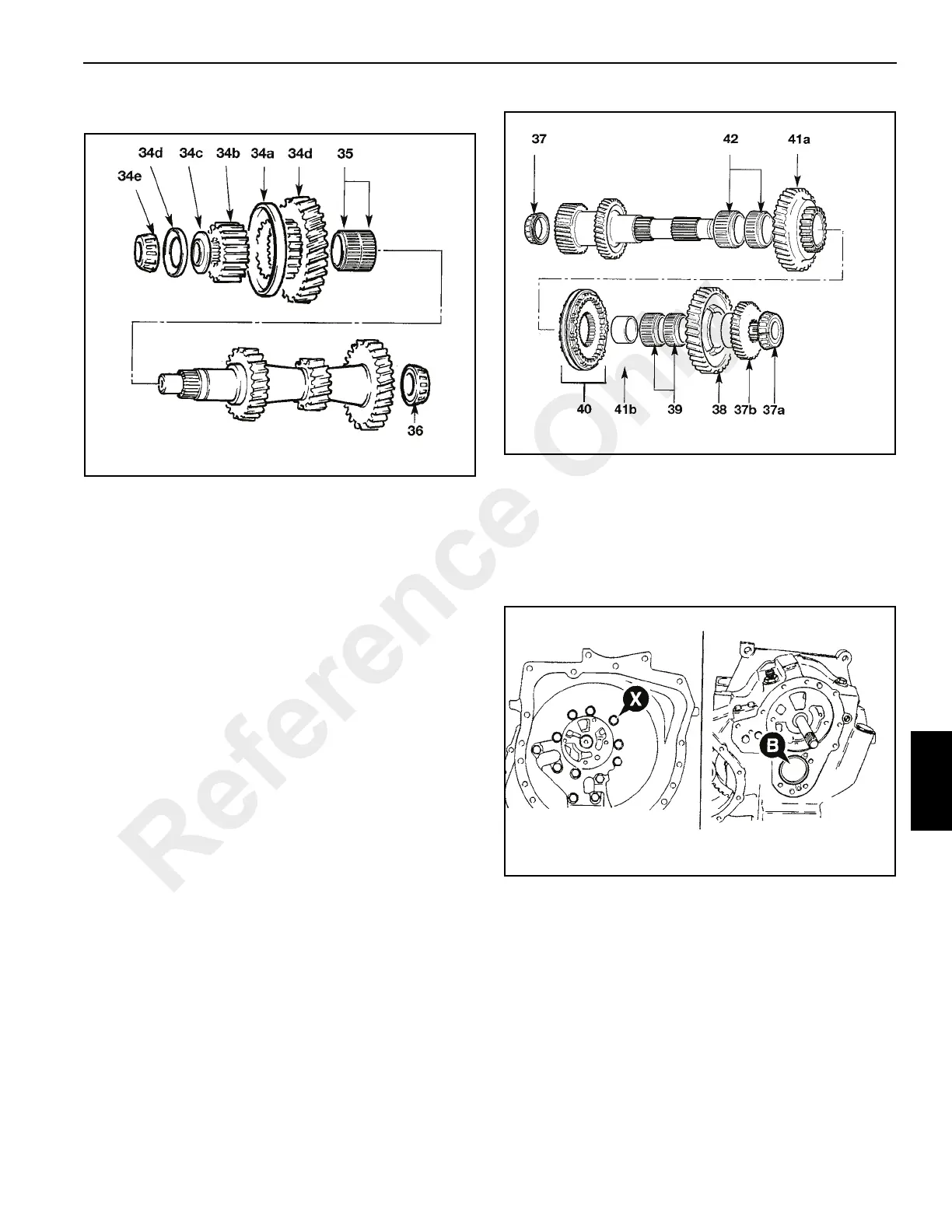

36. Remove bearing 36 from converter end of mainshaft

using press a suitable.

Layshaft

37. Remove the bearing 37 (Figure 7-34). Remove 4WD

transfer gear 37b and bearing 37a from layshaft. On

2WD machines a spacer is fitted in place of the transfer

gear.

38. Liftoff 1st gear 38.

39. Remove 1st gear needle roller bearings 39.

40. Note that the 1st/2nd synchro unit 40 is of a different

design to the 3rd/4th gear unit. There are components

which may be lost during removal unless care is taken.

Hold the unit together with the synchro cones on each

side and lift off. Keep the synchro cones, rings and hubs

in their original relationship.

41. Use a press to push off 2nd gear 41a, synchro assembly

40 and 1st gear needle roller track ring 41b.

42. Remove 2nd gear needle roller bearings 42.

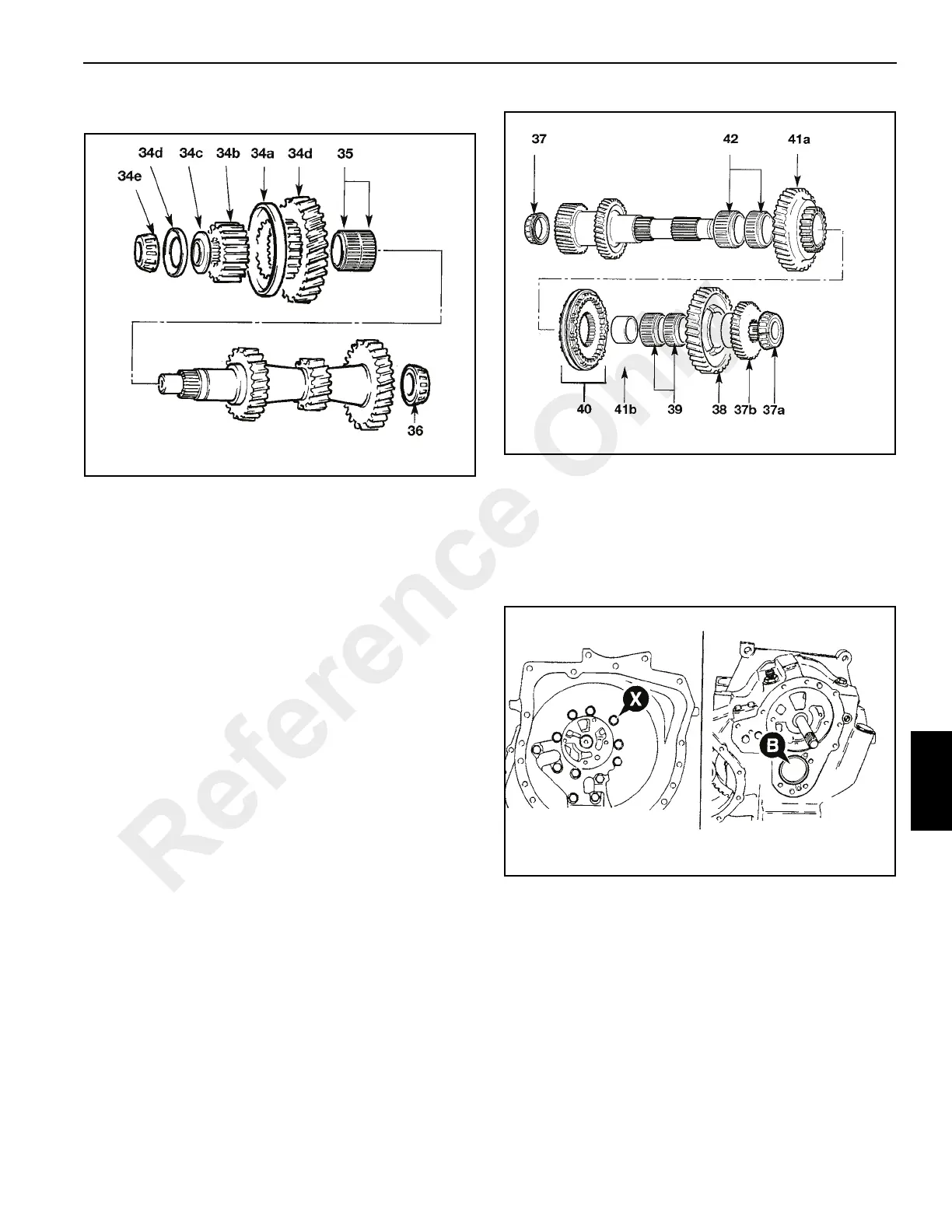

Setting Ring Removal

The mainshaft and layshaft end float is controlled by a

threaded 'setting ring' screwed into the casing.

To enable access to the mainshaft setting ring the torque

converter housing must be removed. Undo the 12 fixing bolts

X (Figure 7-35) and remove the housing. The setting ring is

located at position B.

To enable access to the layshaft setting ring the bearing

cover must be removed. Undo the 4 fixing bolts Y,

(Figure 7-36) remove the cover and discard the gasket

beneath. The setting ring is located at position C.

If the bearings or shaft are to be renewed the associated

setting ring must be removed and discarded as follows:

Reference Only

Loading...

Loading...