11-35

5540F/YB5515 SERVICE MANUAL STRUCTURALS

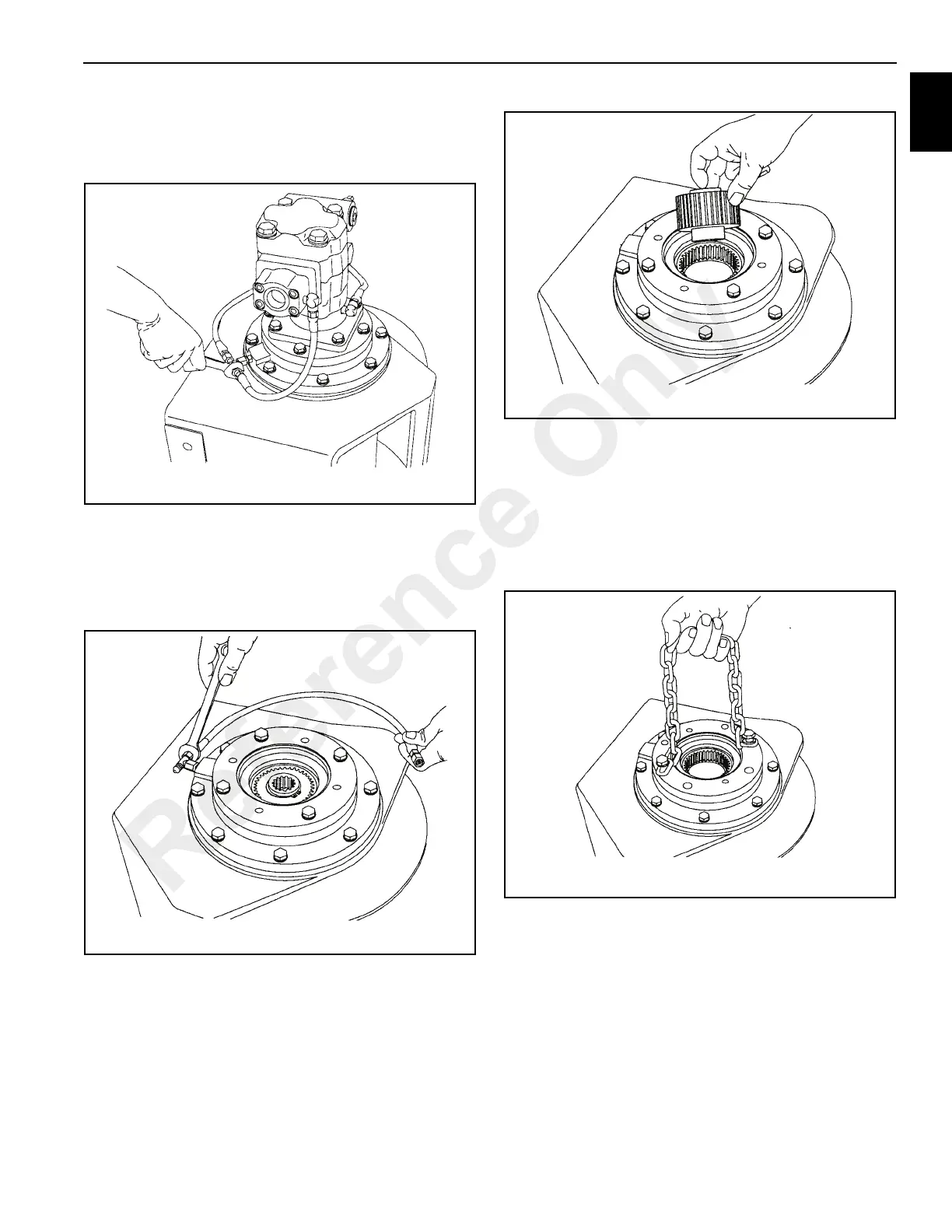

3. Begin disassembly by removing the oil level plug and

standing the winch on the bearing support end. Tag and

remove the hydraulic hoses that connect the brake valve

and manifold to the brake cylinder (Figure 11-63).

4. Remove the capscrews securing the motor, and lift the

motor off the winch. Remove and discard the o-ring

installed on the pilot of the motor.

5. Tag and remove the hoses and fittings from the brake

cylinder release port (Figure 11-64).

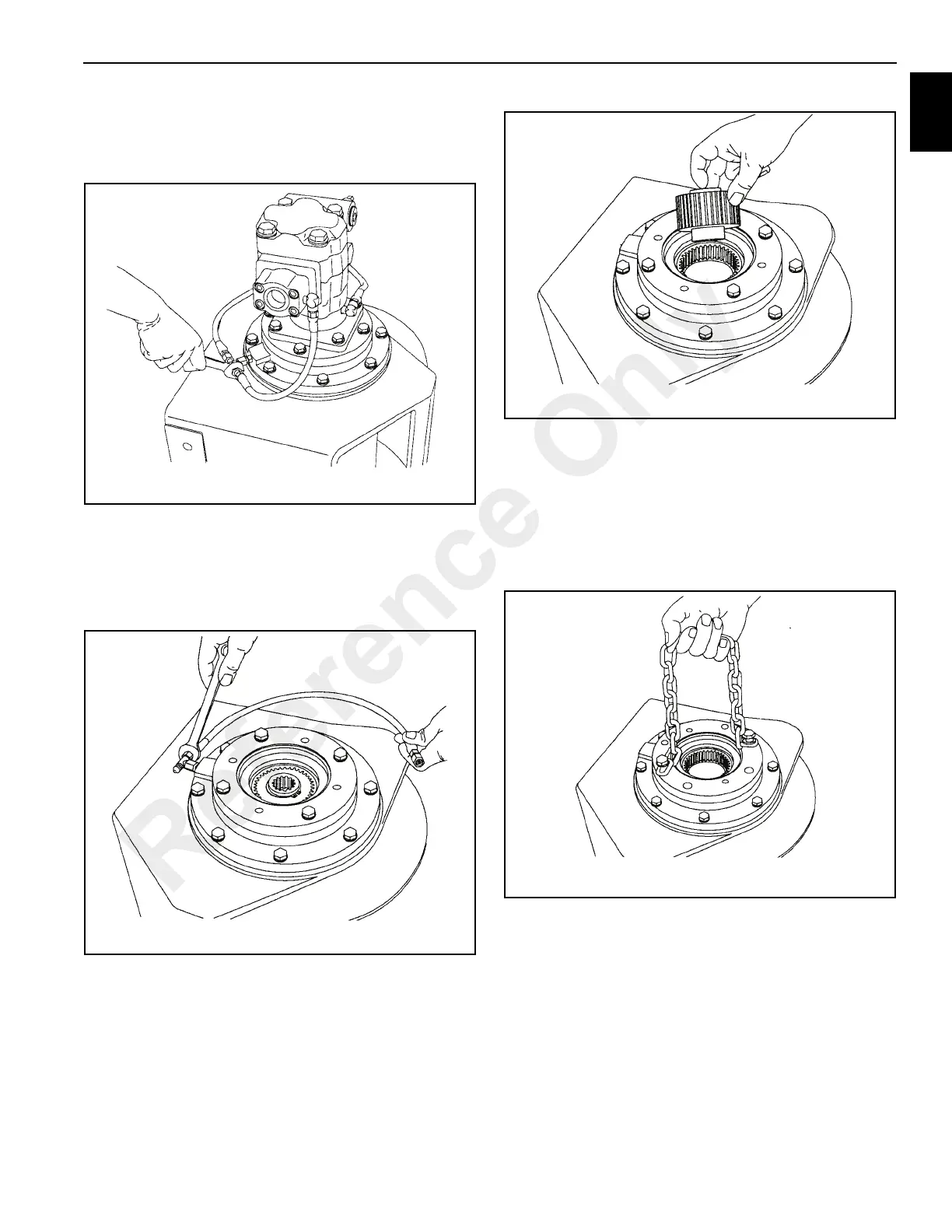

6. Remove the brake clutch (Figure 11-65) assembly from

the motor support. Refer to “Brake Clutch Service,” for

additional information.

7. Remove the motor support capscrews and install two (2)

capscrews and a short piece of chain (Figure 11-66) into

the motor mounting bolt holes. Using the chain as a

handle, lift the motor support out of the brake cylinder

being careful to avoid damaging the sealing surfaces.

Remove and discard the O ring and backup ring from the

motor support. Refer to “Motor Support-Brake Cylinder

Service” for additional information.

8. Remove the brake cylinder capscrews and install two (2)

capscrews and a short piece of chain into the motor

support mounting bolt holes. Using the chain as a

handle, lift the brake cylinder out of the drum and base,

being careful to avoid damaging the sealing or bearing

surfaces. Refer to “Motor Support-Brake Cylinder

Service” for additional information.

9. Using two heel type pry bars (Figure 11-67) placed

between the primary planet carrier and the drum

closure, pry upward to remove the drum closure.

Reference Only

Loading...

Loading...