• DOK-DIAX02-DDS02.1*ANA-ANW1-EN-E1,44 • 12.96

90

8. Final commissioning work

8. Final

commissioning

work

8.1. Preparations for

running the axis with an

NC control system

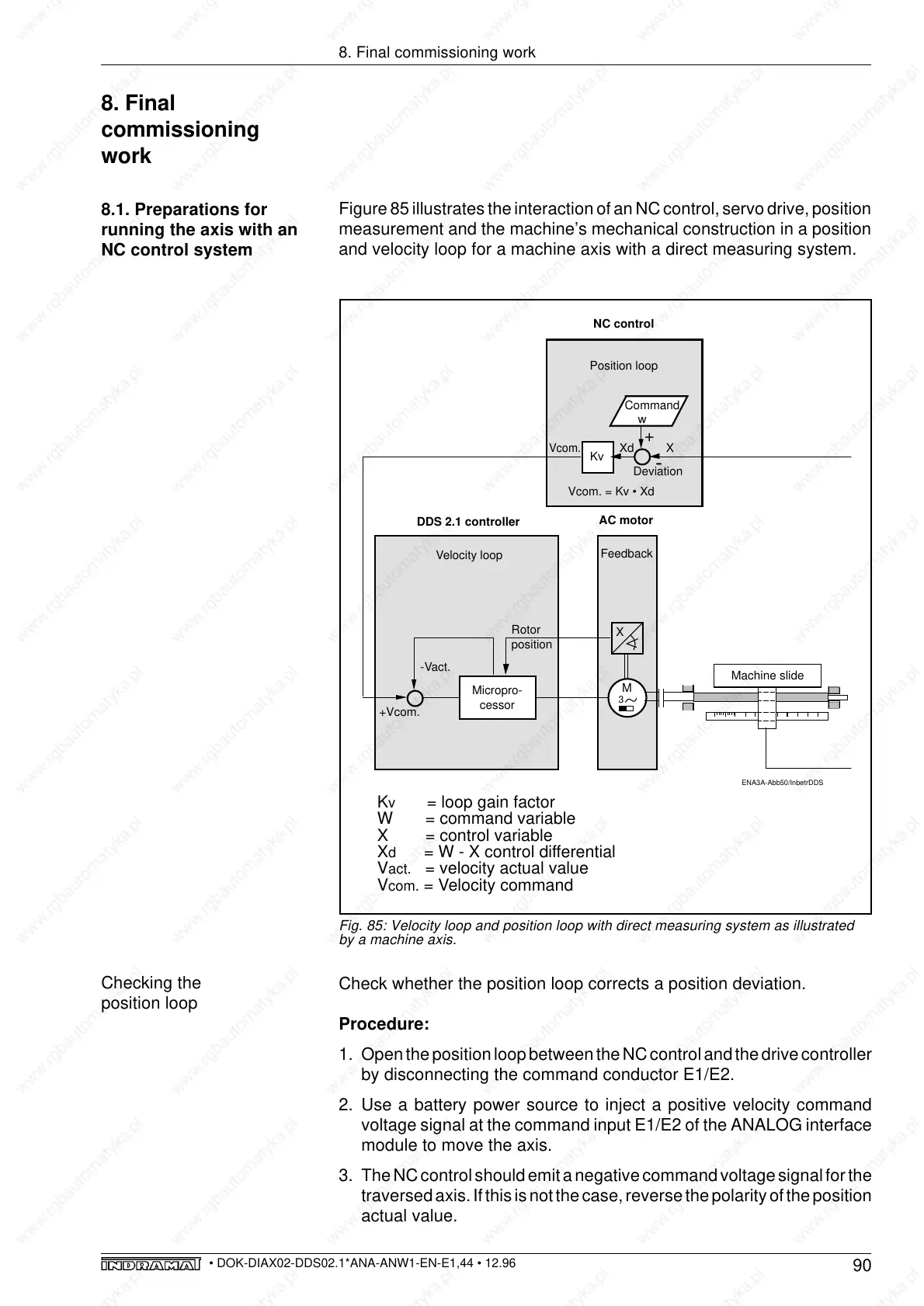

Figure 85 illustrates the interaction of an NC control, servo drive, position

measurement and the machine’s mechanical construction in a position

and velocity loop for a machine axis with a direct measuring system.

Fig. 85: Velocity loop and position loop with direct measuring system as illustrated

by a machine axis.

Position loop

NC control

Command

w

Vcom.

Vcom. = Kv • Xd

Deviation

Machine slide

AC motor

Feedback

Velocity loop

-Vact.

+Vcom.

Micropro-

cessor

Kv

-

M

3

Xd X

+

ENA3A-Abb50/InbetrDDS

X

Rotor

position

DDS 2.1 controller

K

v

= loop gain factor

W = command variable

X = control variable

X

d

= W - X control differential

V

act.

= velocity actual value

V

com.

= Velocity command

Checking the

position loop

Check whether the position loop corrects a position deviation.

Procedure:

1. Open the position loop between the NC control and the drive controller

by disconnecting the command conductor E1/E2.

2. Use a battery power source to inject a positive velocity command

voltage signal at the command input E1/E2 of the ANALOG interface

module to move the axis.

3. The NC control should emit a negative command voltage signal for the

traversed axis. If this is not the case, reverse the polarity of the position

actual value.

Loading...

Loading...