• DOK-DIAX02-DDS02.1*ANA-ANW1-EN-E1,44 • 12.96

64

When stopped, servo axes must be secured against involuntary start-up

if such a movement could cause injury to personnel or damage to

machinery. INDRAMAT provides protection of this type in the form of an

optional holding brake.

The holding brake for MDD motors is not designed as a service

brake. If applied with the motor running, it will wear out after

approx. 20,000 motor revolutions.

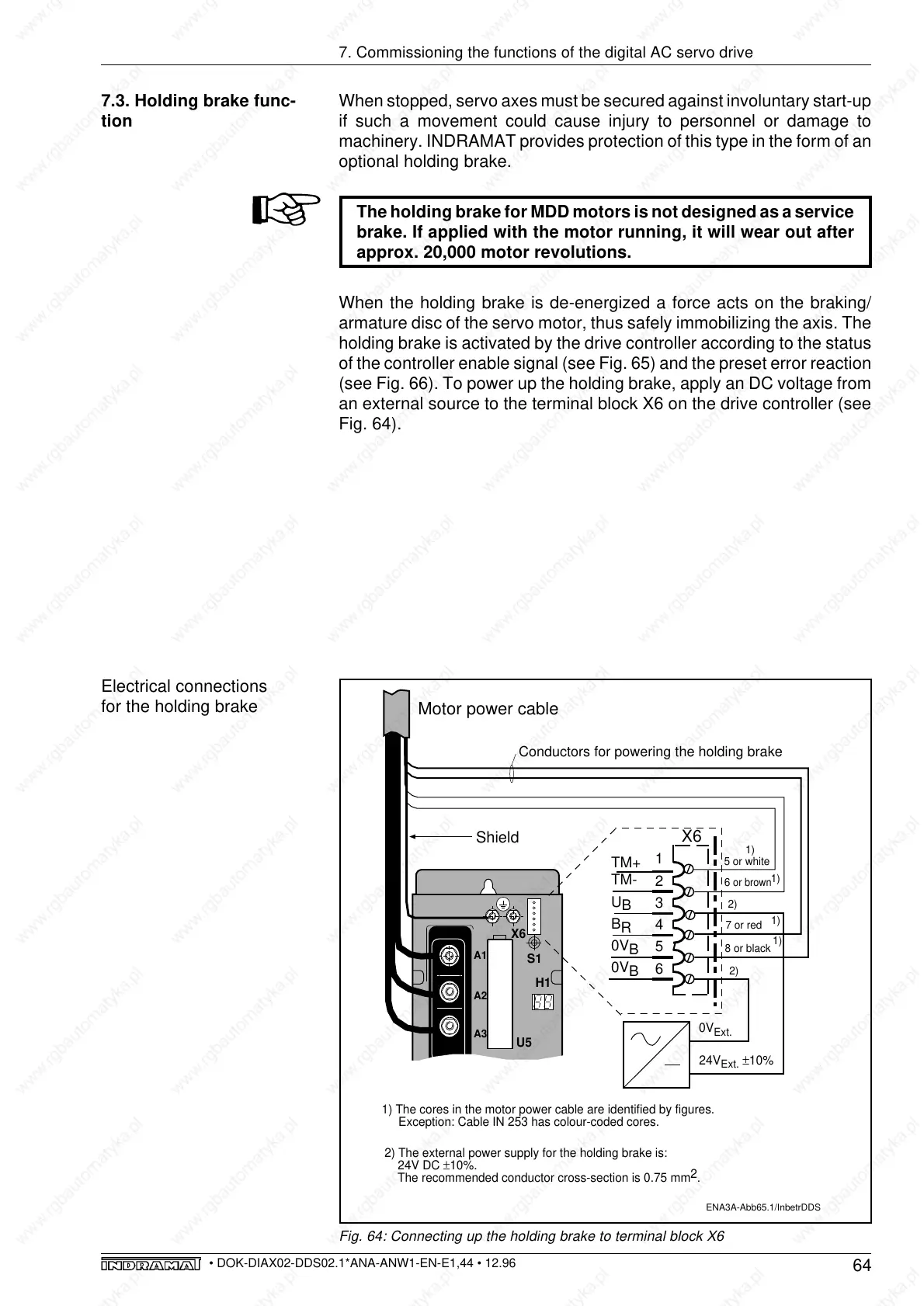

When the holding brake is de-energized a force acts on the braking/

armature disc of the servo motor, thus safely immobilizing the axis. The

holding brake is activated by the drive controller according to the status

of the controller enable signal (see Fig. 65) and the preset error reaction

(see Fig. 66). To power up the holding brake, apply an DC voltage from

an external source to the terminal block X6 on the drive controller (see

Fig. 64).

7.3. Holding brake func-

tion

7. Commissioning the functions of the digital AC servo drive

Fig. 64: Connecting up the holding brake to terminal block X6

Electrical connections

for the holding brake

S1

A3

A1

A2

X6

H1

ENA3A-Abb65.1/InbetrDDS

1

2

3

4

5

6

X6

Shield

U5

Motor power cable

±10%

0V

Ext.

24V

Ext.

5 or white

6

or brown

TM+

TM-

U

B

B

R

0V

B

0V

B

7 or red

8 or black

1)

1)

2)

2)

1)

1)

Conductors for powering the holding brake

1) The cores in the motor power cable are identified by figures.

Exception: Cable IN 253 has colour-coded cores.

2) The external power supply for the holding brake is:

24V DC ±10%.

The recommended conductor cross-section is 0.75 mm

2

.

Loading...

Loading...