• DOK-DIAX02-DDS02.1*ANA-ANW1-EN-E1,44 • 12.96

82

Depending on the type of machine and its design, certain operating

conditions may call for torque reduction of the drive.

The DDS 2.1 drive controller allows you to set three different torque

reductions. These are selected and activated by binary coded signals

through the control inputs Ired1 and Ired2.

Enter the desired torque reduction in %. Entering the figure 100 will

produce a torque identical to the continuous zero-speed torque M

dN

of the

uncooled motor. See "nominal torque" in the "AMPLIFIER/MOTOR

PARAMETERS" menu.

Upper and lower limits for entries : 0 to 400.

Procedure:

1. Call up the "TORQUE/CURRENT LIMITS" menu.

2. Select the desired torque reduction.

3. Enter the desired torque.

7. Commissioning the functions of the digital AC servo drive

7.11. Torque reduction

Entering a

reduced torque level

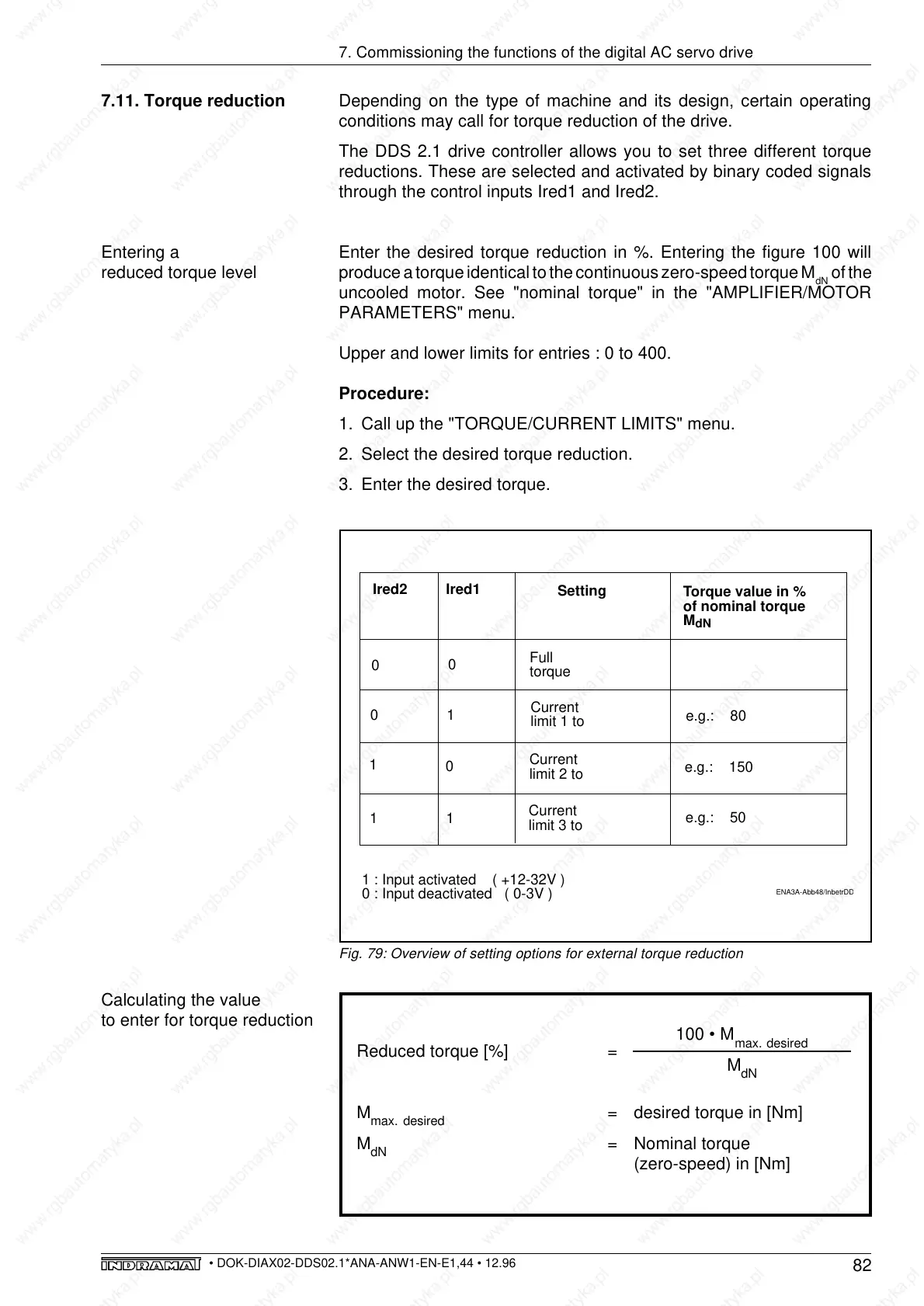

Fig. 79: Overview of setting options for external torque reduction

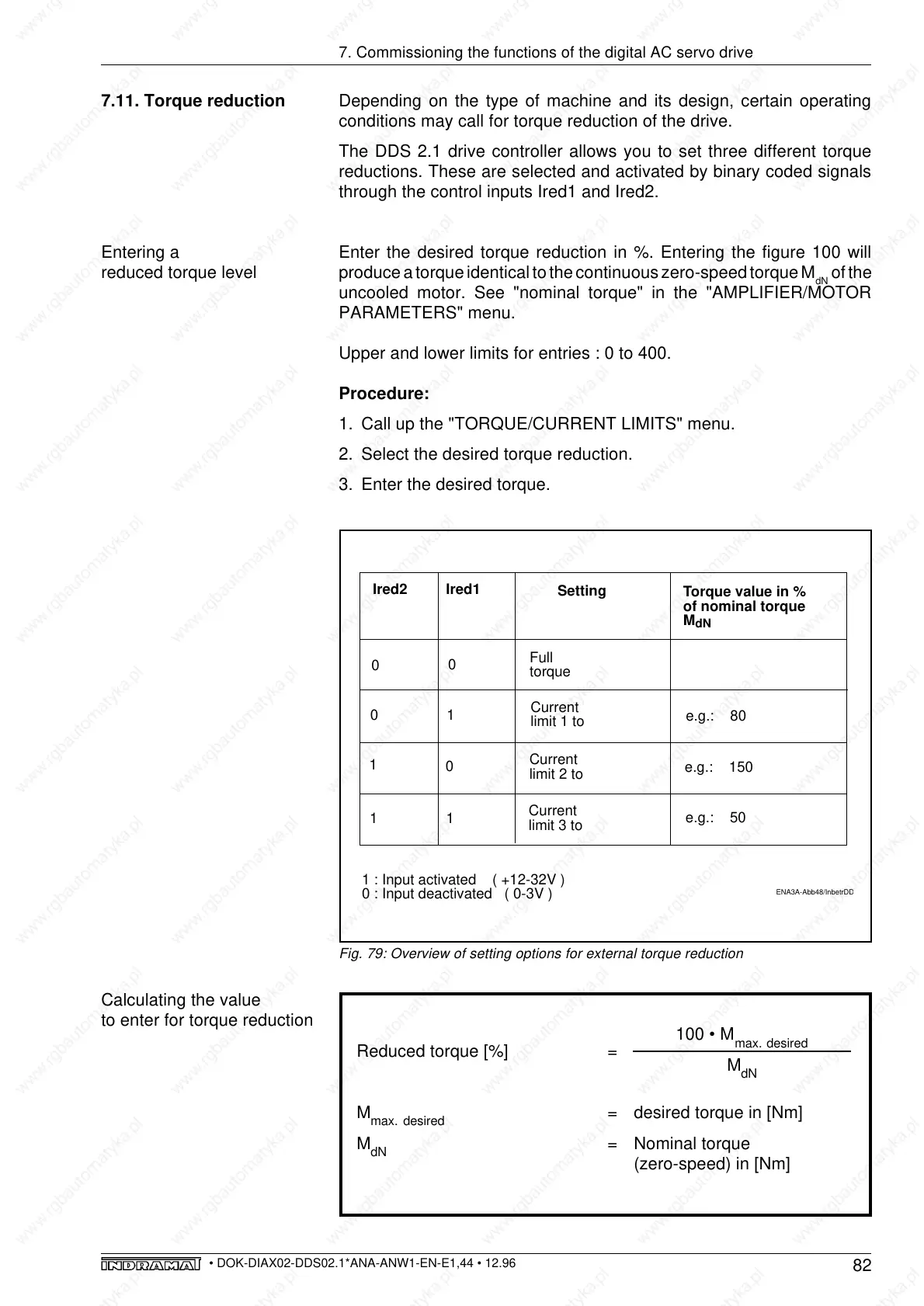

Calculating the value

to enter for torque reduction

Reduced torque [%] =

M

max.

desired

= desired torque in [Nm]

M

dN

= Nominal torque

(zero-speed) in [Nm]

100 • M

max.

desired

M

dN

ENA3A-Abb48/InbetrDDS

Ired2

Ired1

Setting

Torque value in %

of nominal torque

M

dN

e.g.: 80

e.g.: 150

e.g.: 50

0

0

1

1

1

1

0

0

Full

torque

Current

limit 1 to

Current

limit 2 to

Current

limit 3 to

1 : Input activated ( +12-32V )

0 : Input deactivated ( 0-3V )

Loading...

Loading...