McHale V Series Baler

52

6.3.2 Manual greasing system (standard)

The machine is equipped with a manual greasing system, using centralised grease

blocks, for lubricating all of the roller bearings in the machine. These instructions cover

the main components that must be greased at intervals listed below. Apply one stroke

only with a grease gun at each grease point. All other grease points must be greased,

as specified. (See ‘Additional greasing’). McHale recommend using a multipurpose,

extra high performance grease such as Mobilgrease XHP 222 or equivalent NLGI

number 2 grade grease. This will prolong the life of the machine components.

Always wear gloves to avoid direct contact with grease, as this may cause skin

irritation.

NOTE: Oil in the reservoir tank should always be clean

The oil in the oil reservoir tank should always be clean, strained and free

of any impurities during top-up, as this will ensure proper operation and

lubrication.

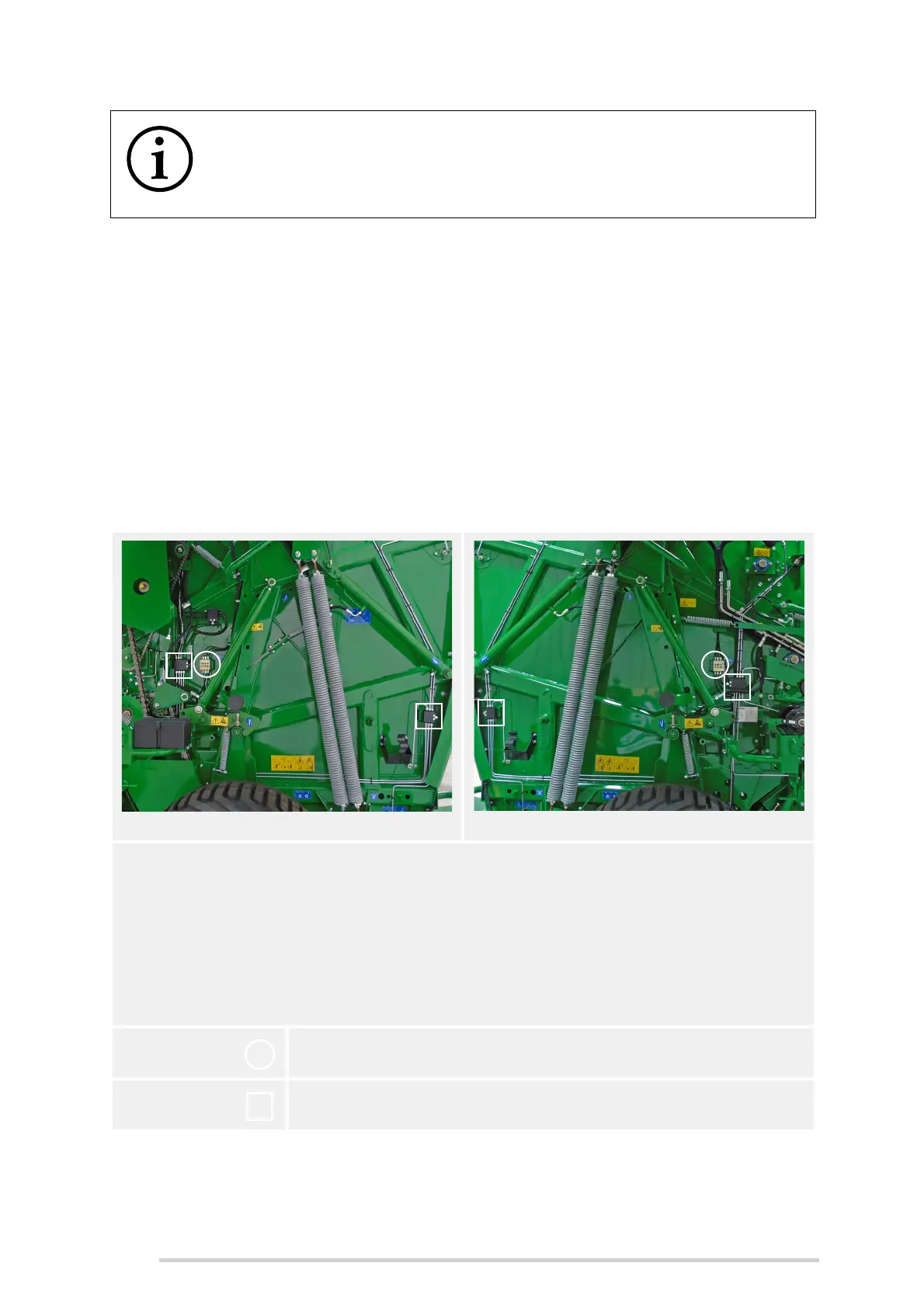

Grease blocks DS

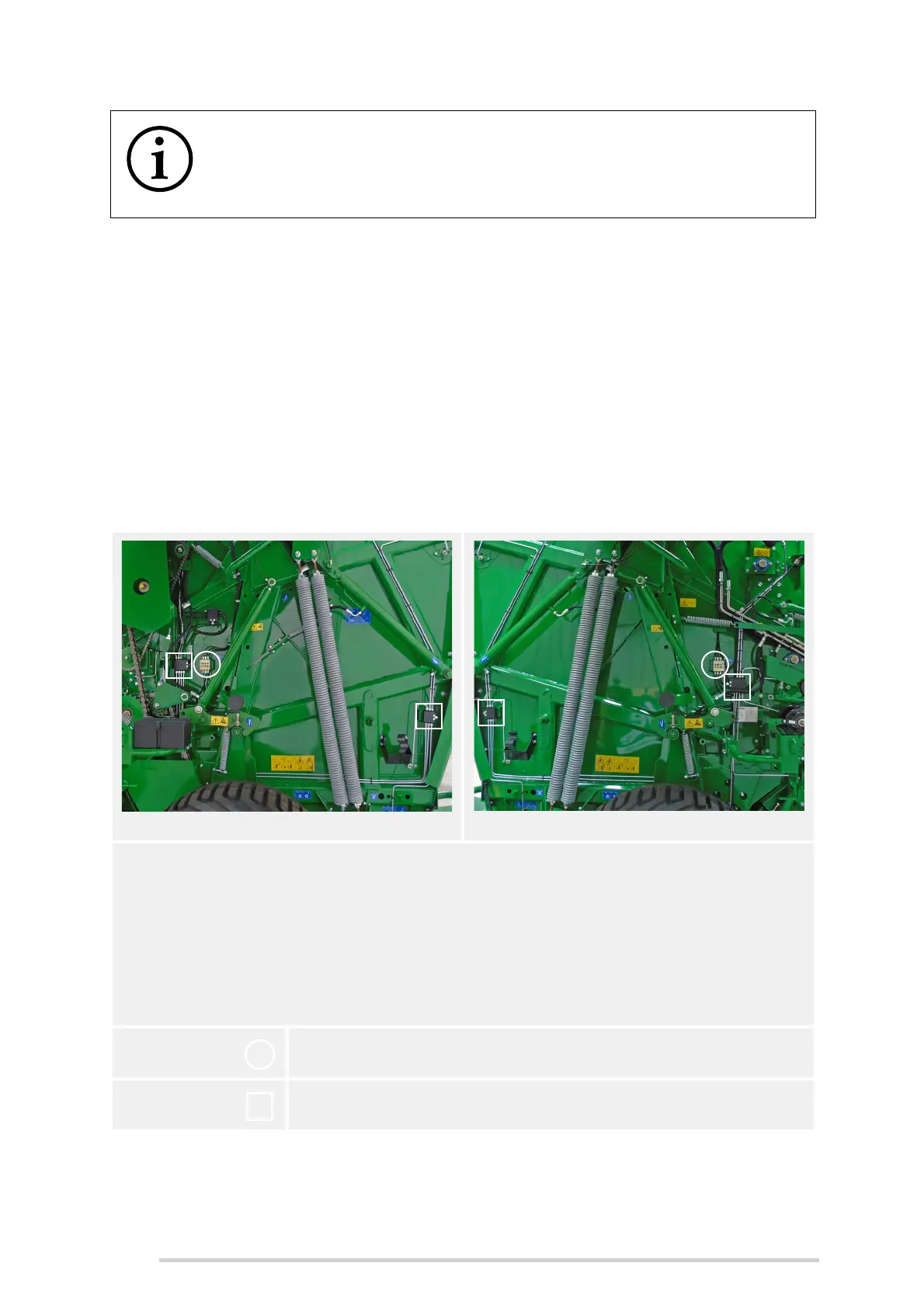

Grease blocks NDS

The baler’s drive side (DS) and non-drive side (NDS) are greased manually at three

centralised grease blocks.

Two serve the bearings on the chamber rollers and rotor bearing (and pick-up drive

gears on the LHS). These are to be greased after every 1,200 bales approximately.

One serves other bearings and bushings via flex pipes and should be greased after

every 300 bales approximately.

Grease every 300 bales

Grease every 1,200 bales

Loading...

Loading...