DET2/3

31

Calibration check tools

Calibration check tools

The instrument's calibration should be checked, before and after each test, against the calibration check tool.

Instrument calibration check

1. Make sure that the mode switch is set to Off.

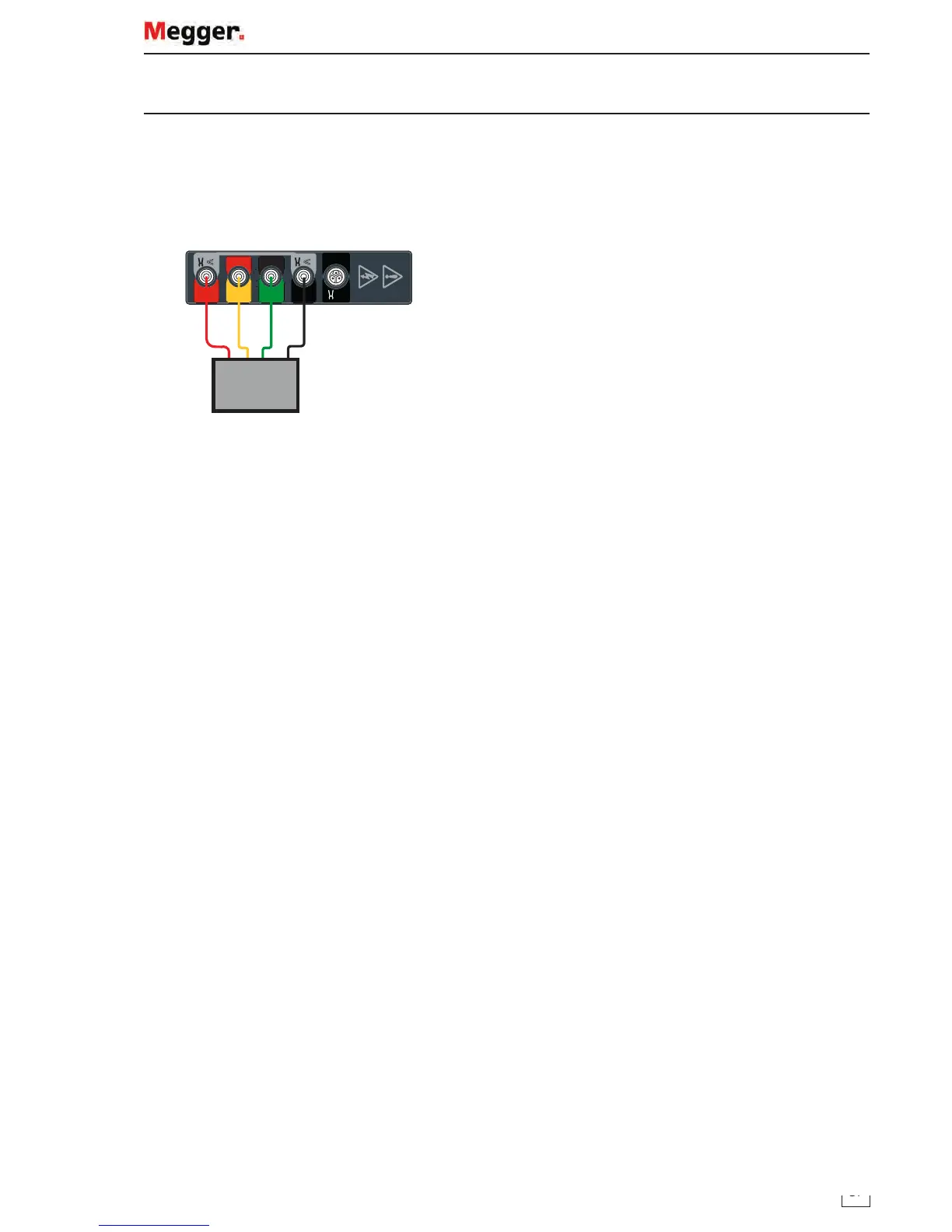

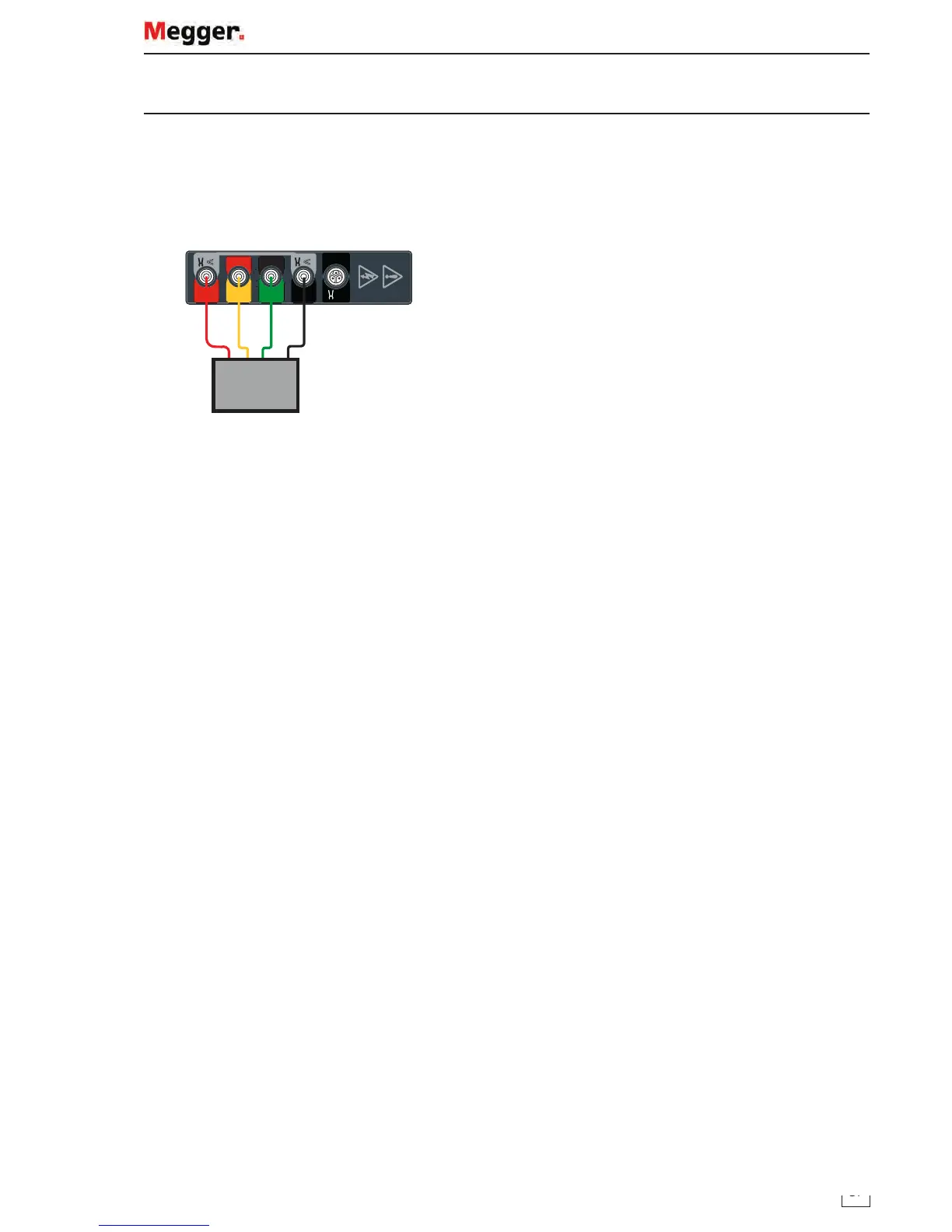

2. Connect the instrument as shown:

C1

CAT IV 300V

P1

P2

C2

E

ES

S

H

I

V

E

X

Y

V

MVC1010 MVC1010

MCC1010

I

Calibration

adaptor

3. Set the function switch to 2P, 3P or 4P.

4. Start a test:

Press and release TEST.

The instrument completes pre-measurement checks.

The resistance is shown and should match the value written on the calibration check tool.

Checking instrument accuracy

Instrument accuracy: 0.5% (+ 2 digits). At 25 Ω is this gives an allowed measurement range of +/- 0.145 Ω.

Calibration check tool accuracy: 0.1%. At 25 Ω this gives an allowed variation of 0.025 Ω.

Therefore a test, which uses the 4 pole position, will produce the following bands:

25 + 0.145 + 0.025 = 25.17 (a figure greater than this is out of specification)

25 + 0.145 – 0.025 = 25.12 (a figure between 25.12 and 25.17 is possibly out of specification)

25 – 0.145 + 0.025 = 24.88 (a figure between 24.88 and 25.12 is in specification)

25 – 0.145 – 0.025 = 24.83 (a figure less than this is out of specification)

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Loading...

Loading...