Operating instructions for a round-belt conveyor system with vertical conveyor RF with VF

File: BA_RFmitVF_9750655_EN_2017-05.docx Update: 2018-04-10 9750655

Design and construction subject to change without prior notice!

MEIKO Maschinenbau GmbH & Co. KG, Englerstraße 3, D-77652 Offenburg, Tel.: +49 (0)781/203-0, Fax: +49 (0)781/203-1174

10.2.3 Inspection doors on the vertical conveyor

The inspection doors on the vertical conveyor are secured with a lock and may be opened

at any time. An inspection flap is located behind the inspection doors and is secured with

a safety switch and a lock. During shut down, the inspection doors and the inspection flap

can be opened with the appropriate key in order to turn the machine back on.

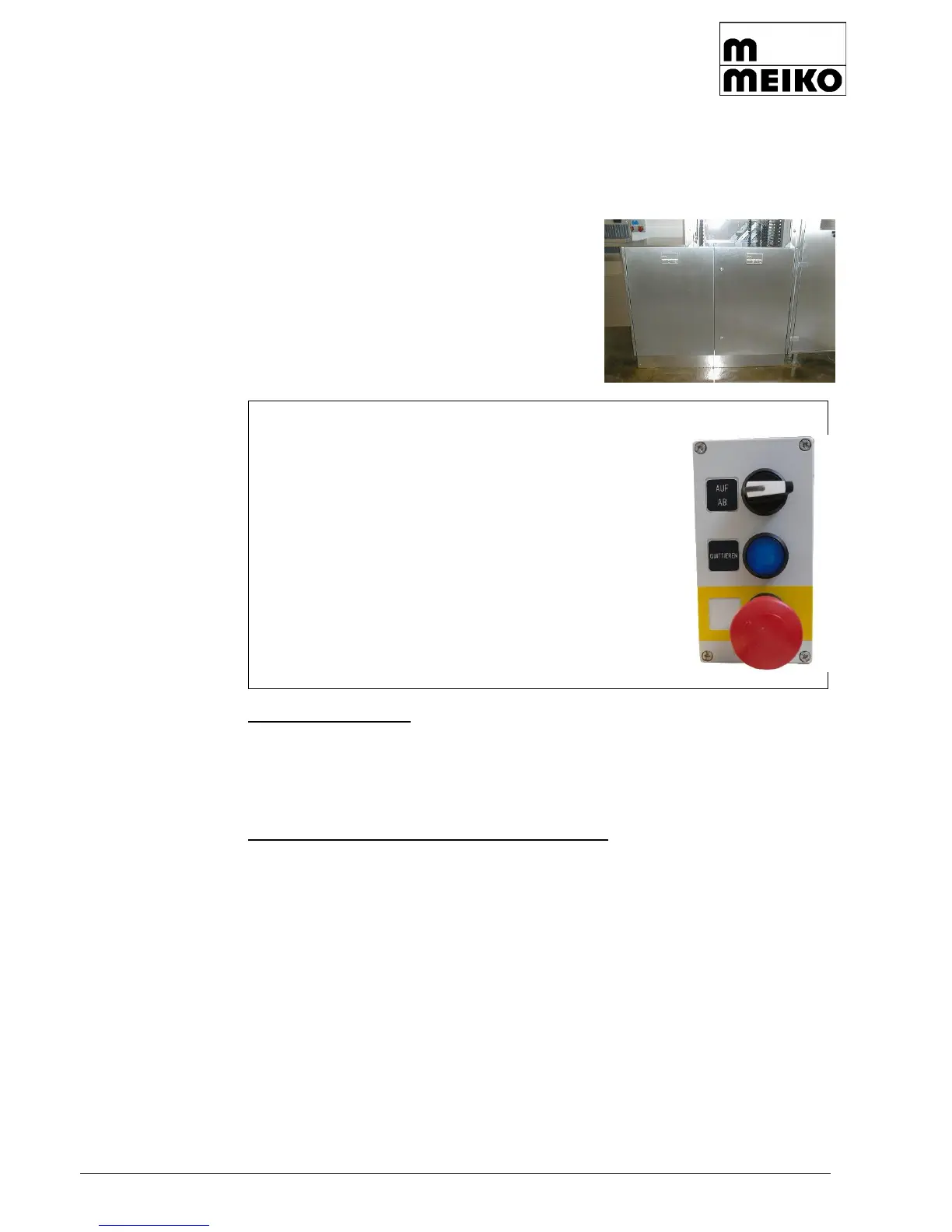

The following controls are to be found behind

the inspection doors:

On/off key:

Conveyor up/down for inspection and cleaning purposes.

Light-up "acknowledge fault" key

for shut downs in the infeed and outfeed areas.

Once the machine has been turned back on again by removing a

tray or serviette, the inspection flap must be closed and the

"acknowledge" key pressed. Then the installation will work again.

EMERGENCY STOP

An EMERGENCY STOP is provided for safety. When activated,

this turns off only the operational area as defined by safety

technicians.

Following a shut down:

Open inspection door and inspection flap.

Remedy fault.

Close inspection flap and inspection door.

Press the "acknowledge" key on the nearest control panel.

The conveying system will turn back on automatically.

Following activation of the EMERGENCY STOP key:

The switch is released by turning the EMERGENCY STOP key to the right.

Press the "acknowledge" key on the electrical switch cabinet.

Press the ON key on the control panel to start up the installation.

Loading...

Loading...