Operating instructions for a round-belt conveyor system with vertical conveyor RF with VF

File: BA_RFmitVF_9750655_EN_2017-05.docx Update: 2018-04-10 9750655

Design and construction subject to change without prior notice!

MEIKO Maschinenbau GmbH & Co. KG, Englerstraße 3, D-77652 Offenburg, Tel.: +49 (0)781/203-0, Fax: +49 (0)781/203-1174

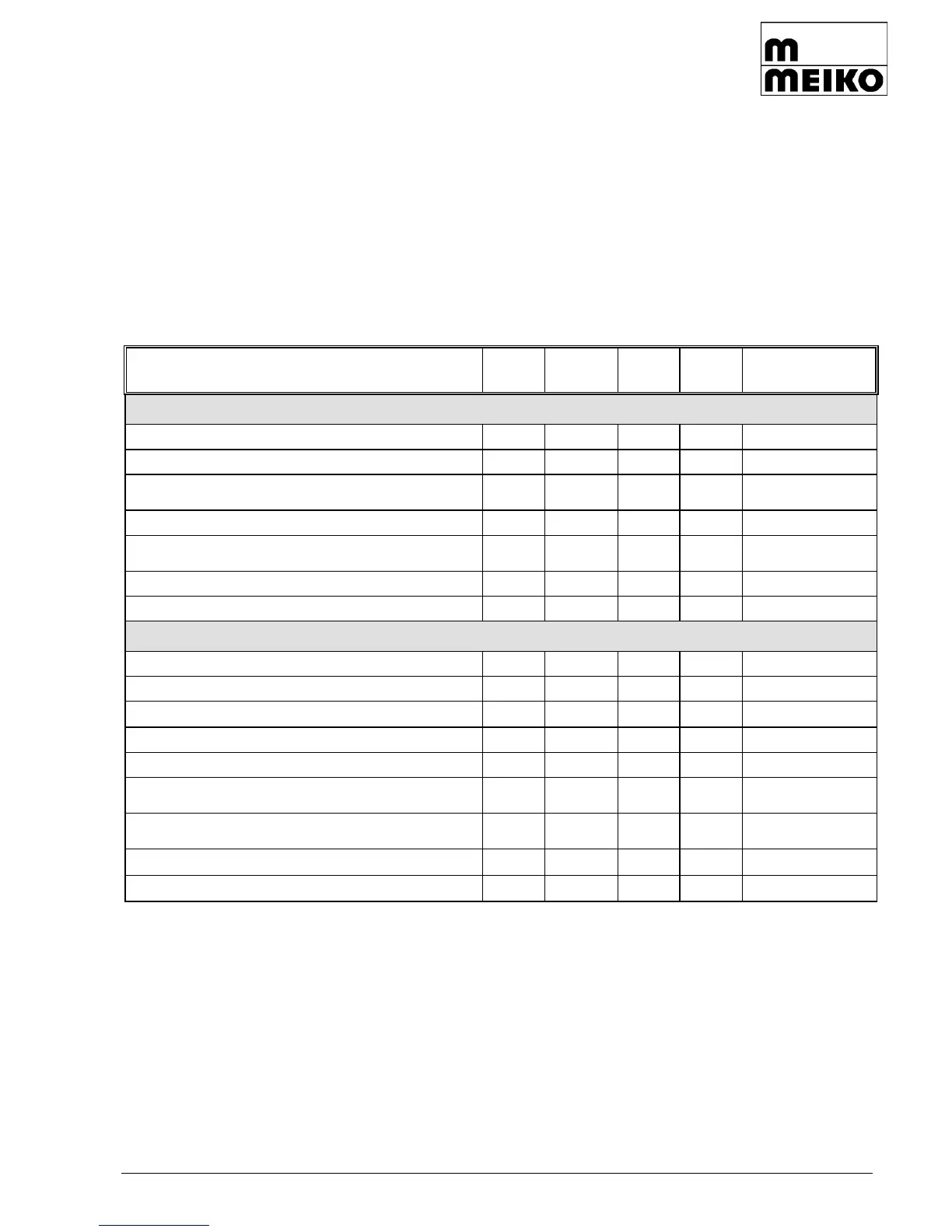

15 Maintenance

Maintenance work may only be carried out when the conveying system is turned off. Addi-

tionally, the main switch for the conveying system must be switched off and locked.

The accident protection systems on components presenting a risk of catching or crushing

(round belt guides, corner guides) must be checked at regular intervals. This should take

place at maintenance intervals of six months.

Existing safety systems must not be removed!

We recommend concluding a maintenance contract with our subsidiary in order to ensure

a long service life.

Please also read the chapter on "conveying systems with suspended and clad tracks"

Measured values/note

on completion

Check temperature and smooth running of all bearings

Check round belt pulleys for function and for damage

Check round belt pulleys for mechanical damage, tension

and surface condition (whether sticky)

Check round belt guidance system for damage

Check corner rollers top and bottom for function and dam-

age

Check drive motors for running noise and ventilation

Check tray guides before, on and after corners

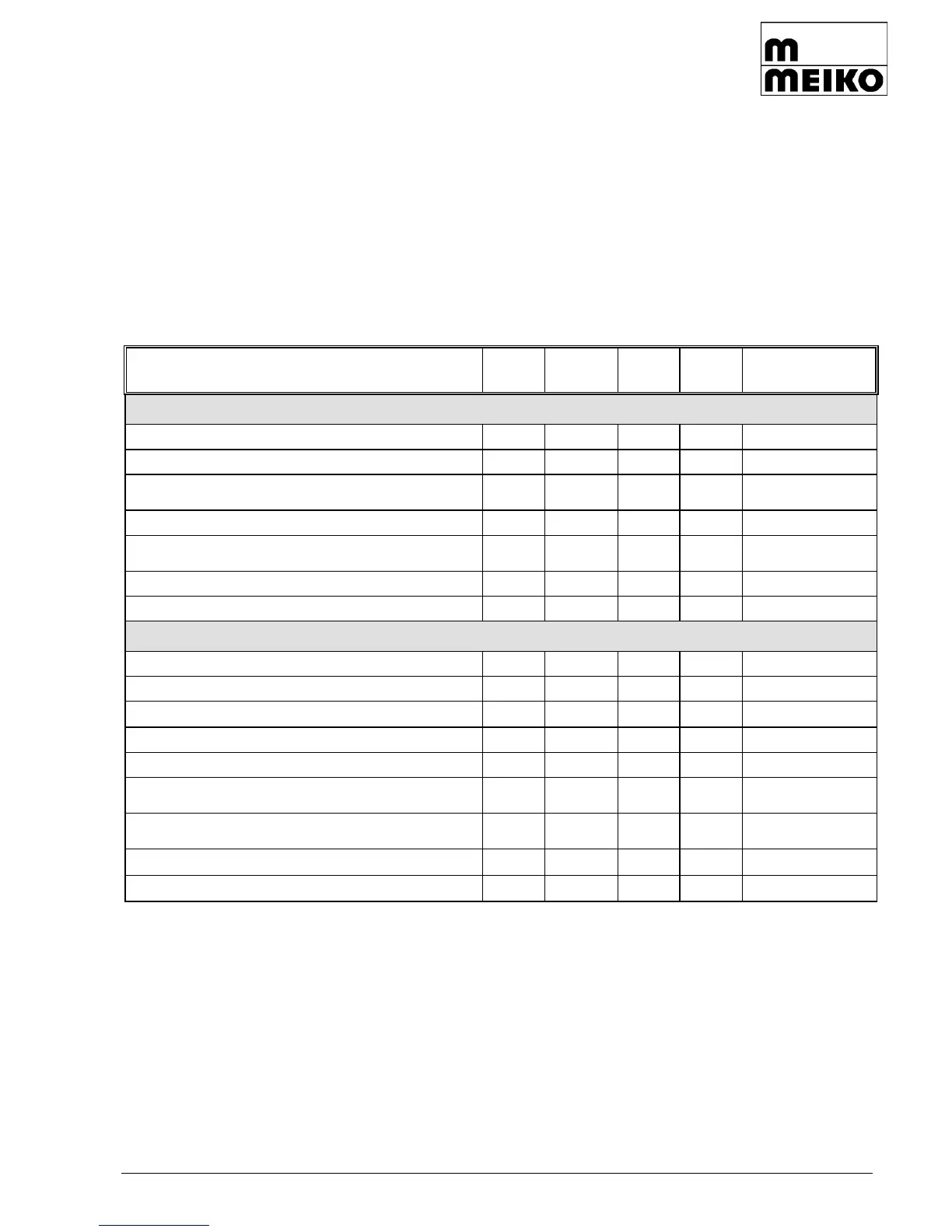

15.2 Tray infeed on vertical conveyor

Check light barriers and light switches are working

Check light barriers and light switches are secure

Check flat belts for tension and damage

Check temperature and smooth running of all bearings

Check round belt pulleys for function and for damage

Check round belt pulleys for mechanical damage, tension

and surface condition (whether sticky)

Check corner rollers top and bottom for function and dam-

age

Check drive motors for running noise and ventilation

Check tray guides before, on and after corners

Loading...

Loading...