Design and construction subject to change without prior notice!

MEIKO Maschinenbau GmbH & Co. KG, Englerstraße 3, D-77652 Offenburg, Tel.: +49 (0)781/203-0, Fax: +49 (0)781/203-1174

12.2 Daily cleaning

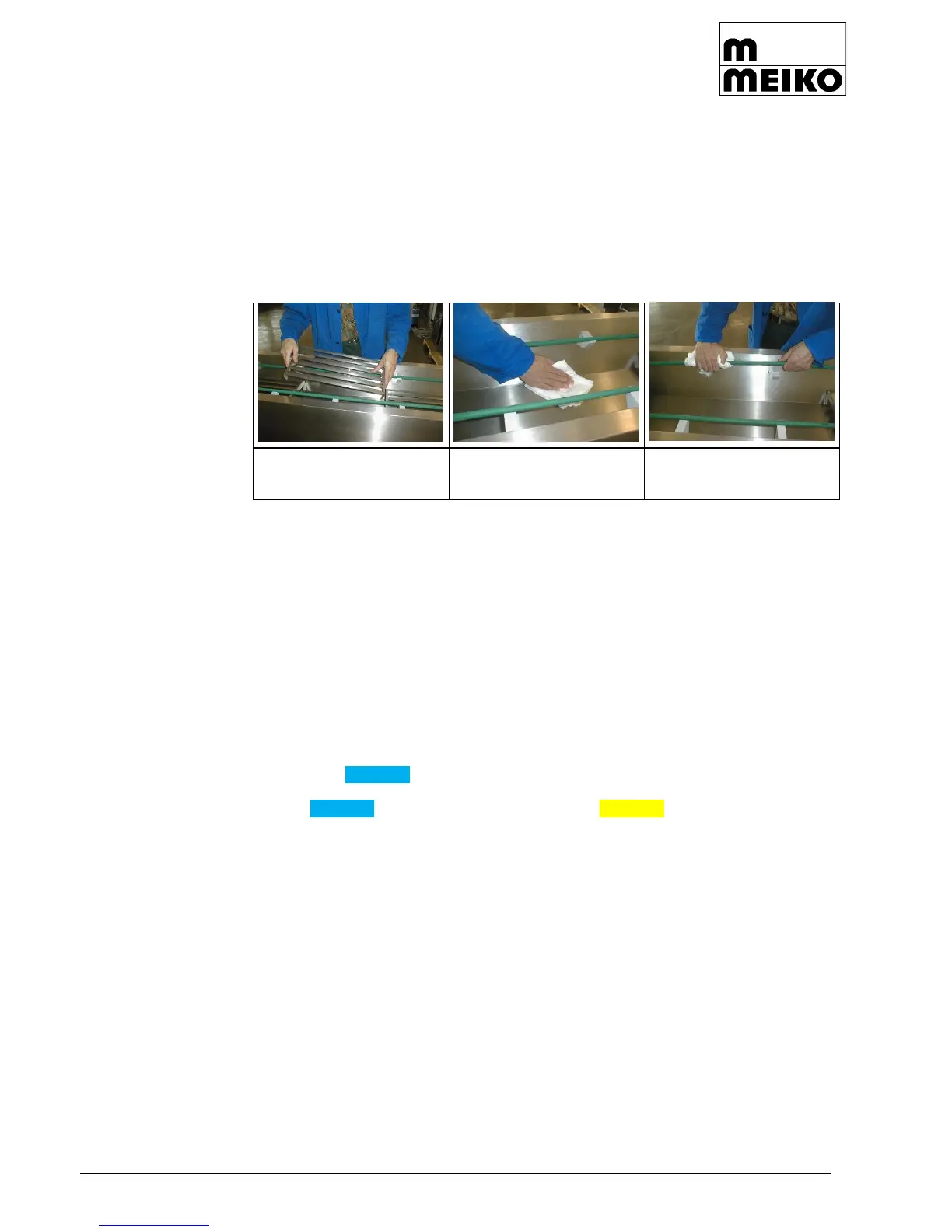

Sticky dirt should be removed from the round belt glide surface and the round belt.

Make sure that no cleaning additives are used that become sticky after drying.

Cleaning agents containing alcohol, acid and chlorine as well as disinfectants, etc. should

be avoided, as they attack the round belts and pulleys.

We recommend using mildly alkaline cleaning agents when cleaning.

A weekly general clean is sufficient for the rest of the conveyor area, including, for example,

the removal of serviettes.

For operational and hygiene reasons, the installation must be cleaned appropriately for the

level of dirt.

The drive area, guide sections and switch cabinet area of the installation must not be

cleaned with a high pressure cleaner.

Spraying electrical switch components and devices, such as on/off switches, drive motors

etc., is prohibited.

12.3 Cleaning the vertical conveyor

Press the blue "CLEAN" button on the touch panel.

The blue "CLEAN" button will turn yellow, as shown: "CLEAN" and the notification "run-

ning lane 1 empty" will appear

The conveying system now runs while empty.

On completion of the predetermined number of cycles (trays), the control turns off and the

"up/down" key is released for manual operation on the vertical conveyor control panel.

Loading...

Loading...