Operating instructions for a round-belt conveyor system with vertical conveyor RF with VF

File: BA_RFmitVF_9750655_EN_2017-05.docx Update: 2018-04-10 9750655

Design and construction subject to change without prior notice!

MEIKO Maschinenbau GmbH & Co. KG, Englerstraße 3, D-77652 Offenburg, Tel.: +49 (0)781/203-0, Fax: +49 (0)781/203-1174

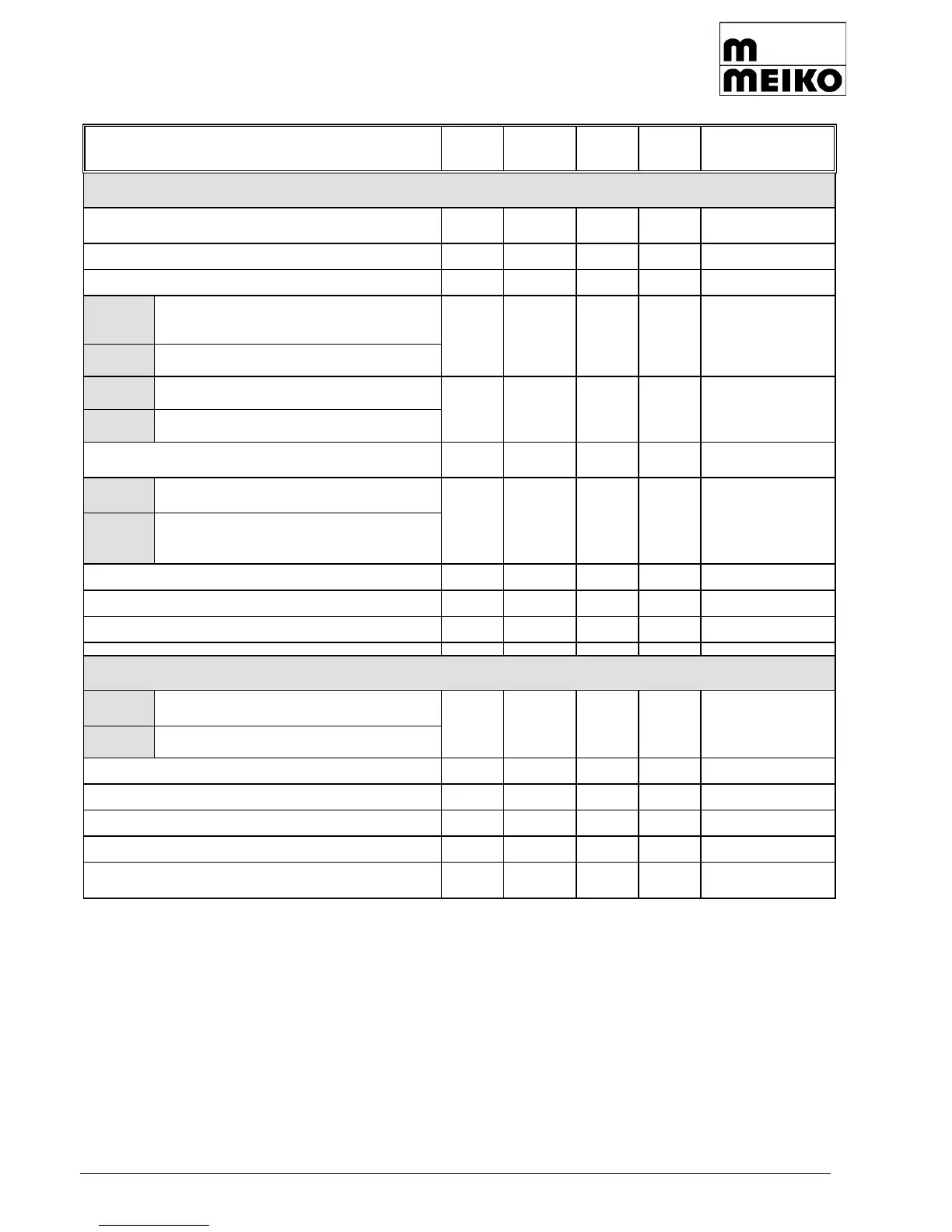

Measured values/note

on completion

Check working, mounting and secure fitting of inductive

proximity switch

Check light barrier works properly and is securely fitted

Check temperature and smooth running of all bearings

Clean between the block chains (if the platform

is curved, this must also be cleaned)

Check the platforms for damage

Check the forks for damage

Check spacing (max. 3 mm) between inductive proximity

switch and switch rod

Check platform mounting in toothed belt

(check sleeve for position).

Check platform mounting in toothed belt

(check sleeve for position).

Align fork.

Check drive motors for running noise and ventilation

Check drive chain for lubrication and grease if necessary

Clean forward and reverse glide rails

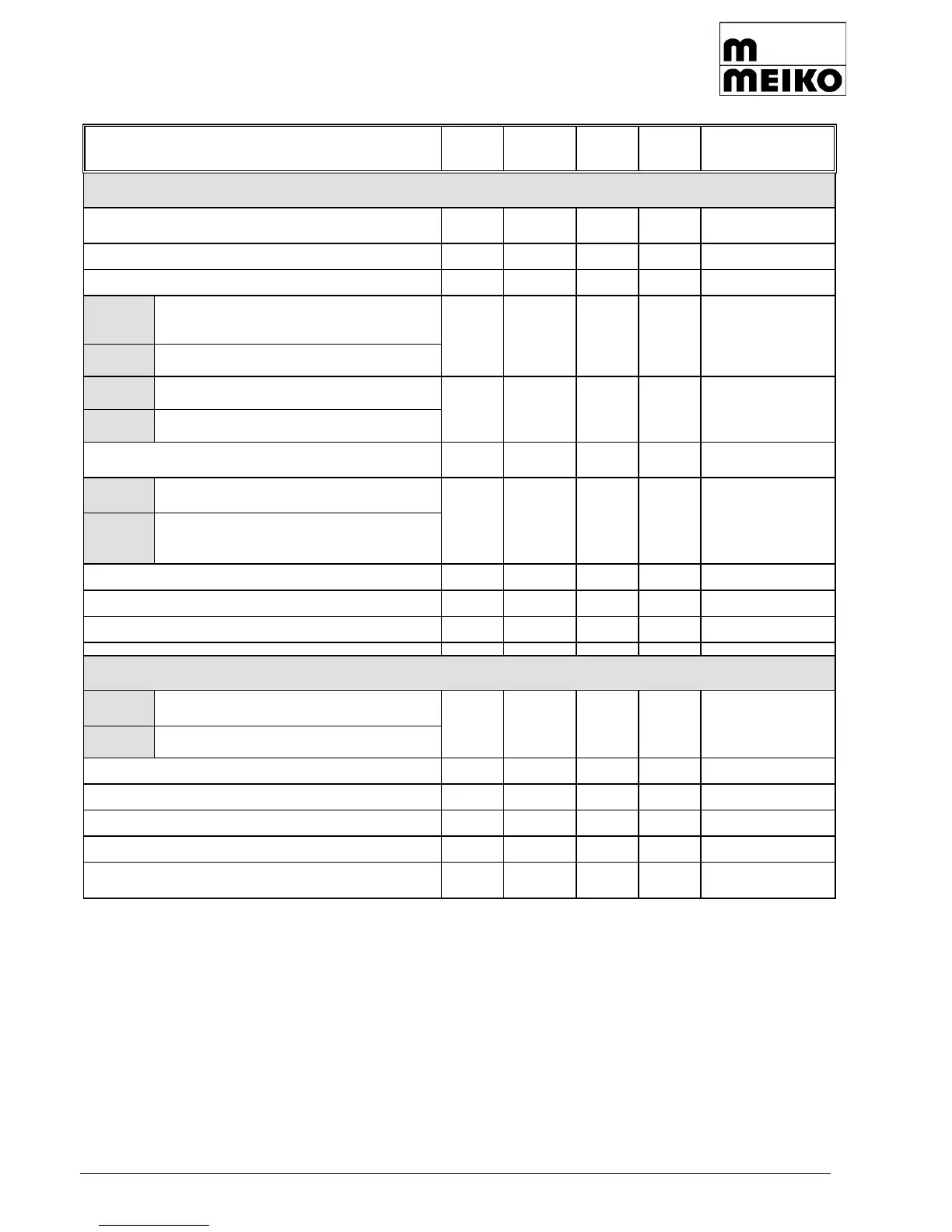

15.4 Vertical conveyor - outfeed

Check height of transition between plat-

form/tray belt

Check lateral tray guides for damage

Check flat belts for tension and damage

Check temperature and smooth running of all bearings

Check round belt pulleys for function and for damage

Check light barriers and light switches are working and se-

curely fitted

Loading...

Loading...