13 Malfunctions

69

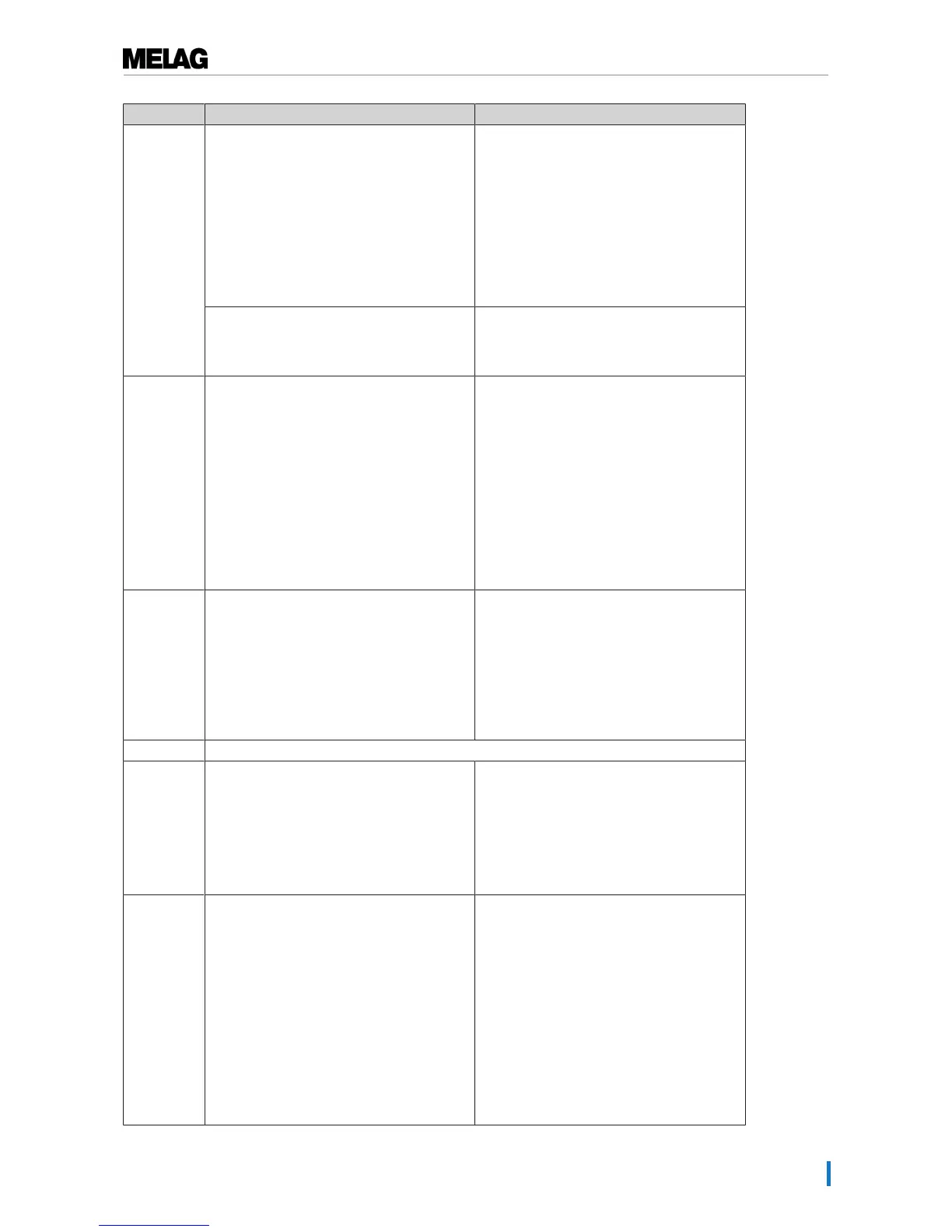

Incident Possible causes What you can do

75 When using the internal storage tank:

a) Insufficient feed water in the right-hand

chamber of the internal storage tank.

b) The float switch of the right-hand chamber

of the internal storage tank (feed water) is

stuck.

a) Check the water level of the feed water in

the right-hand chamber of the internal

storage tank and refill with feed water if

necessary.

b) Check the float switch as follows:

1. Remove the tank lid from the storage tank.

2. Remove the filling funnel if present.

3. Move the float in the right-hand chamber

of the storage tank (feed water side from

below in the tank) up and down repeatedly to

restore its free-movement.

When using a MELAG water treatment unit:

c) The water supply is set to “INTERNAL"

despite external water supply.

When using a MELAG water treatment unit:

c) Set the feed water supply in the “Settings”

menu (function) to "EXTERNAL” (see Water

supply [}page 52]).

76 a) The Quick-Program B and S are mainly

used. These programs do not do not have

automatic rinsing.

With connection to the building waste water

outflow:

The waste water cannot flow off. A rinse

must be performed after a further 2 or 3

program runs.

b) The waste water hose is kinked or

installed sagging.

c) The siphon or the building-side waste

water line is blocked.

a) Start another program e.g. the Universal-

Program, Gentle-Program or Prion-Program

to perform the necessary rinsing.

With connection to the building waste water

outflow:

b) Check the installation of the waste water

hose. This must be installed without kinking

or sagging and at a constant decline.

c) Check whether the building siphon is

blocked. Please note: If multiple devices are

operated simultaneously, we recommend the

installation of an additional siphon.

78 a) The left-hand chamber of the internal

storage tank (waste water) is full or was only

incompletely emptied.

b) If the notification is displayed despite an

empty tank, the float switch is blocked.

a) Empty the left-hand chamber of the

storage tank (waste water).

b) Check the float switch as follows:

1. Remove the tank lid from the storage tank.

2. Remove the filling funnel if present.

3. Move the float in the left-hand chamber of

the storage tank (feed water side from below

in the tank) up and down repeatedly to

restore its free-movement.

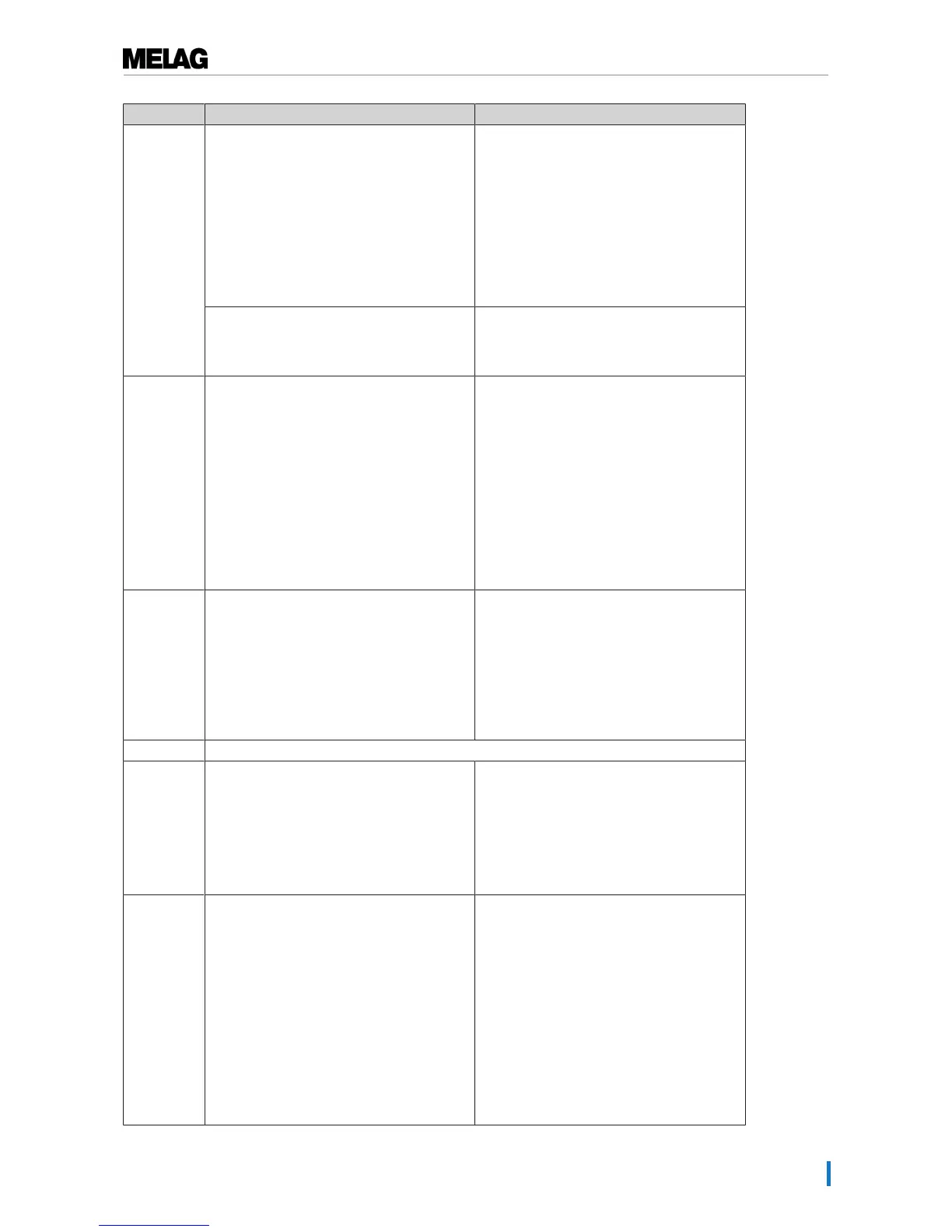

80 see event 78

81 a) The door was not pushed closed for long

enough with sufficient force; as a result, the

thread has become caught.

b)The door spindle and/or the door lock nut

were not oiled regularly and are dry.

a) Close and hold the door with force for c. 3

seconds until the spindle engages in the

door lock and the door is pulled in

automatically. A motor sound is audible.

b) Lubricate the door spindle and the door

lock nut regularly with the oil included in the

scope of delivery (see Oiling the door spindle

[}page 61]).

82 a) There are objects in the door area.

b) A residual vacuum is present in the

sterilization chamber. The pressure

equalization has not been concluded.

c) The door seal sticks to the seal face of the

sterilization chamber.

a) Always keep the area in front of the door

free so that it can open unhindered.

b) 1. Wait two minutes and then confirm the

notification with OK.

2. Should the door not open independently,

switch off the steam sterilizer, wait five

minutes and then switch it back on. Try again

to open the door.

If the door does not open, inform the

authorized customer services/stockist

technician.

c) If the door could be opened, clean the

door seal and the seal face in the sterilization

chamber (see Cleaning [}page 59]).

Loading...

Loading...