13 Malfunctions

70

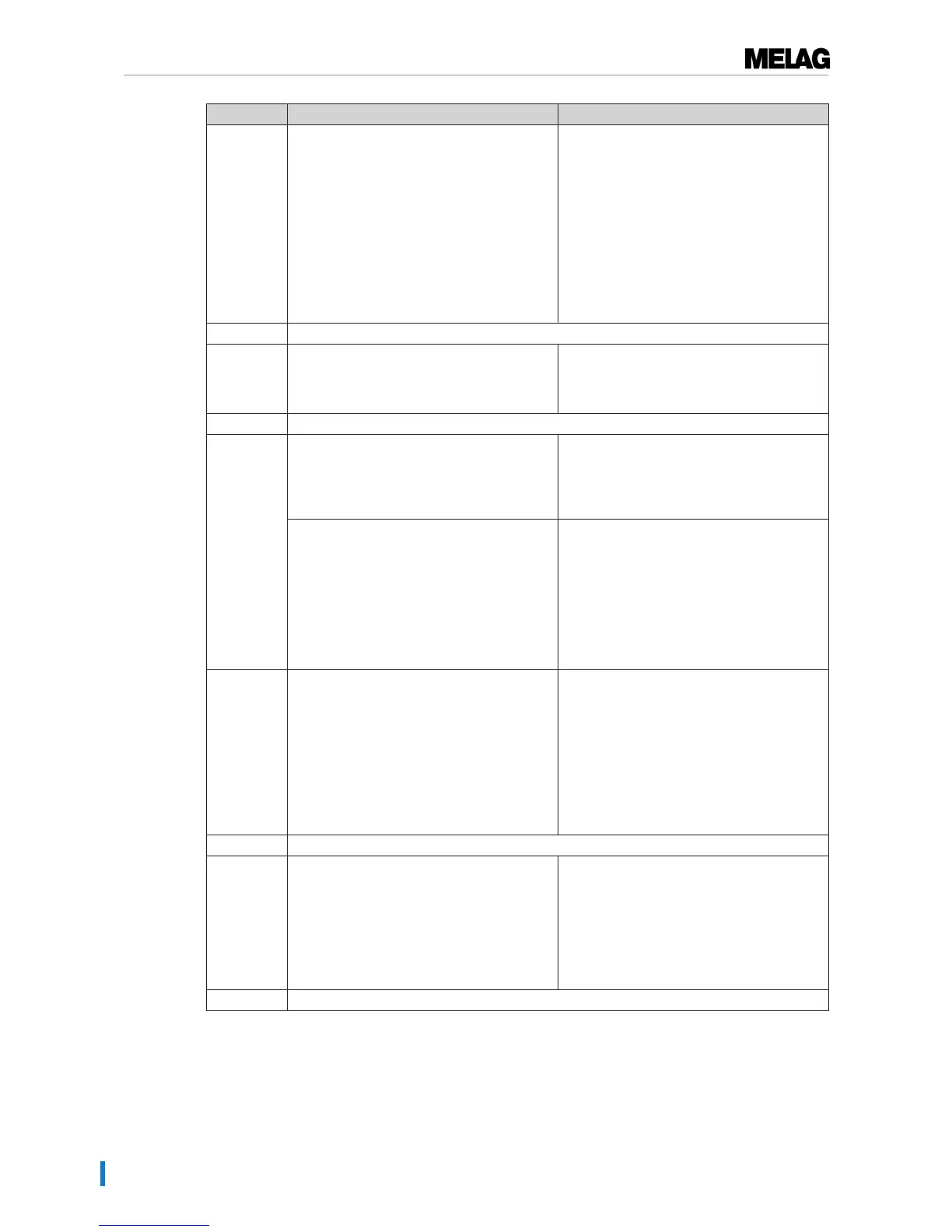

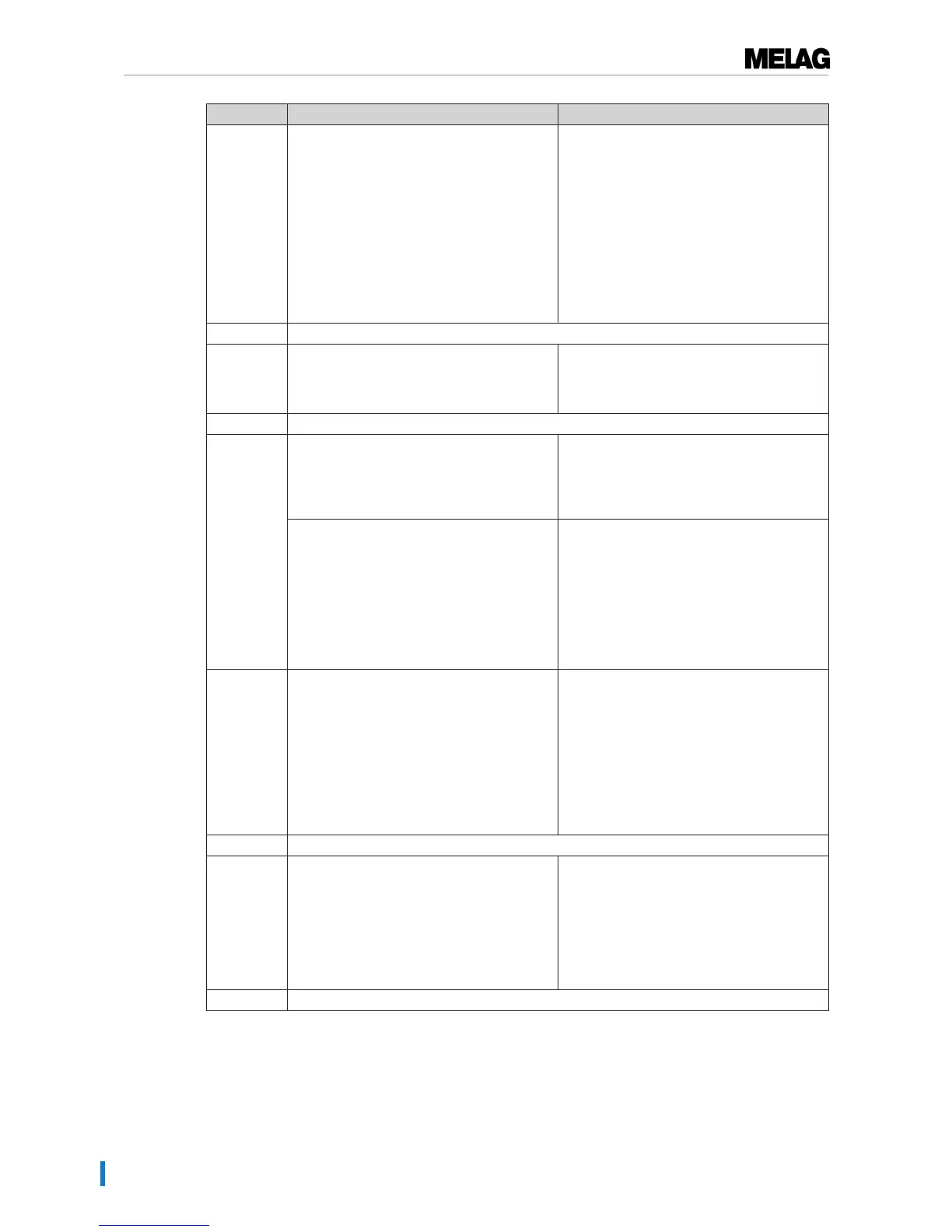

Incident Possible causes What you can do

83 The door does not reach a pressure-tight

state after the program start.

a) The door seal and/or the seal face is

soiled and or damaged.

b) The load blocks the door area.

c) The closing mechanism is stiff.

a) Check the door seal and the seal face in

the sterilization chamber for soiling, foreign

bodies or damage.

b) Check whether the load is blocking the

door.

c) Check the door spindle and the door lock

nut for damage. Clean and oil the door

spindle and the door lock nut with the oil

included in the scope of delivery. Clean and

oil the door spindle and the door lock nut

with the oil included in the scope of delivery

(see Oiling the door spindle [}page 61]).

84 see event 82

86 The door has not been closed correctly upon

program start.

Close and hold the door with force for c. 3

seconds until the spindle engages in the

door lock and the door is pulled in

automatically. A motor sound is audible.

89 see event 86

102 a) The chamber filter “Pressure release” is

blocked.

a) Remove the "Pressure release” chamber

filter (in the rear area of the sterilization

chamber below) and check whether it is e.g.

soiled/blocked by packaging. If necessary,

clean the chamber filter.

With connection to the building waste water

outflow:

The waste water cannot flow off.

b) The waste water hose is kinked or

installed sagging.

c) The siphon or the building-side waste

water line is blocked.

With connection to the building waste water

outflow:

b) Check the installation of the waste water

hose. This must be installed without kinking

or sagging and at a constant decline.

c) Check whether the building siphon is

blocked. Please note: If multiple devices are

operated simultaneously, we recommend the

installation of an additional siphon.

103 The sterile filter is soiled/blocked. 1. Check whether the sterile filter suction

aperture (centre aperture) on the rear panel

of the steam sterilizer is blocked. If yes,

replace the sterile filter.

2. If nothing can be recognized, remove the

sterile filter on the rear panel of the steam

sterilizer and perform a program run without

a load. If the program has been ended

successfully, the sterile filter is blocked. In

this case, replace the sterile filter.

104 see event 103

110 a) The steam sterilizer is overloaded or the

load has been arranged badly.

b) The mains voltage is too low, poor

building voltage supply (e.g. undersized

installation, defective socket, multiple

devices on a single socket/fuse).

a) Comply with the maximum permissible

load quantities (see Loading the steam

sterilizer [}page 22]). Ensure that the load

does not come into direct contact with or

covers the steam injection nozzles.

b) Check the building-side socket / test the

steam sterilizer using a different socket or

circuit.

111 see event 110

Loading...

Loading...