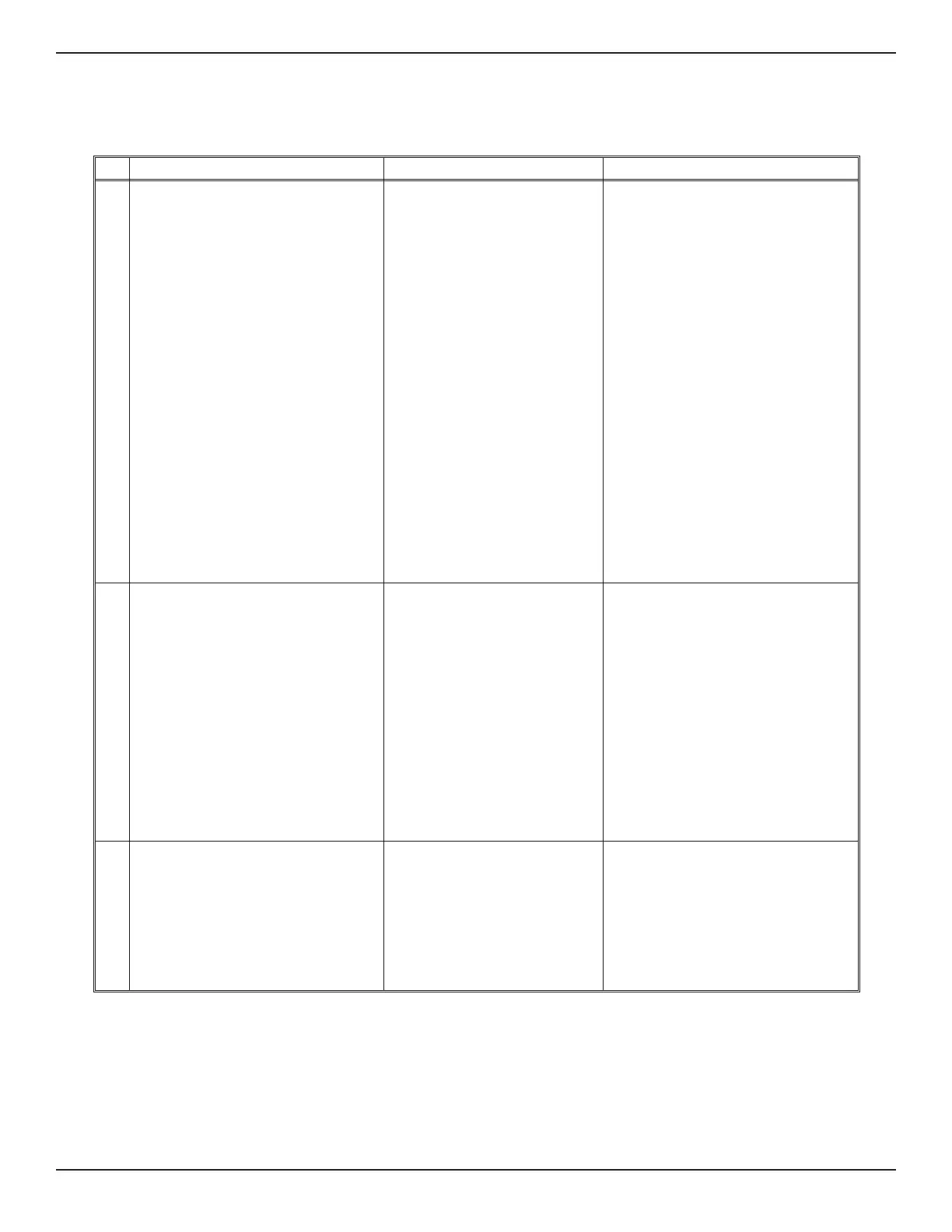

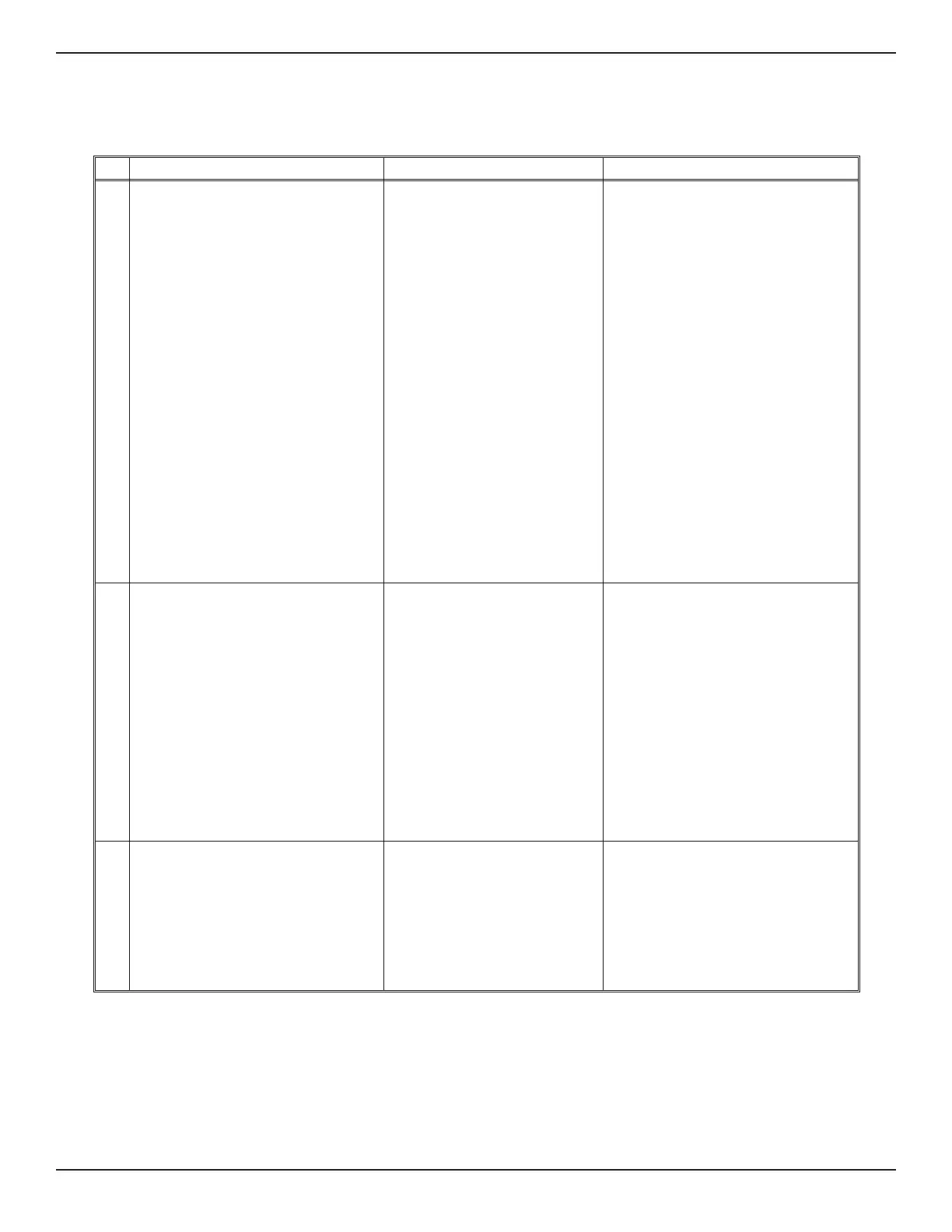

Table 5.1 continued...

Continued on next page...

Symptoms and Clues Possible Cause Try This

4 SYSTEM DOES NOT CONTROL

AT COMMANDED SET POINT

CLUE: The PCS 400 requires an

input pressure higher than the

control output set point, or

pneumatics section is working

improperly.

The source pressure is not

high enough.

----------------------

The cable connecting the

electrical module to the

regulator is disconnected.

----------------------

The solenoid valves are not

opening to let pressure into or

out of the control module.

----------------------

PCS 400 has a pneumatic

leak.

Apply source pressure 10 psi (or

10%) greater than the commanded

set point.

--------------------------

Check the 9 pin connector

Å on

the electrical module and the pcb

connector

à on top of the

regulator. Make sure the regulator

connector is not shorted against

something.

--------------------------

Run the solenoid valve test to verify

that all of the valves are working.

CAUTION: HIGH PRESSURES

COULD BE PRESENT AT THE

GAUGE OUTPUT DURING THE

TEST!

--------------------------

See next section.

5

SYSTEM HAS A PNEUMATIC

LEAK

CLUE: Possible sources for leaks

are solenoids, plumbing, or relief

valves.

Because of the extreme

resolution of the PCS 400,

very small temperature

changes on trapped volumes

of gas will appear as changes

in pressure. The PCS 400 will

control small leaks with no

effect on any control

parameters. The built-in leak

diagnostics are designed to

help troubleshoot problems

but not return absolute

numbers.

Run internal leak test and system

leak test to determine if leak is

inside unit or external. Most internal

leaks appear at solenoid valves,

relief valves and fittings.

6 SYSTEM DOES NOT RESPOND

FROM THE FRONT PANEL

KEYPAD

CLUE: Signals are not being

transferred from the front panel

keypad to the electrical module.

The keypad cable is

disconnected at the front

panel

È or at the electrical

module.

Re-connect the cable.

MAINTENANCE PCS 400

5-4 www.mensor.com

Loading...

Loading...