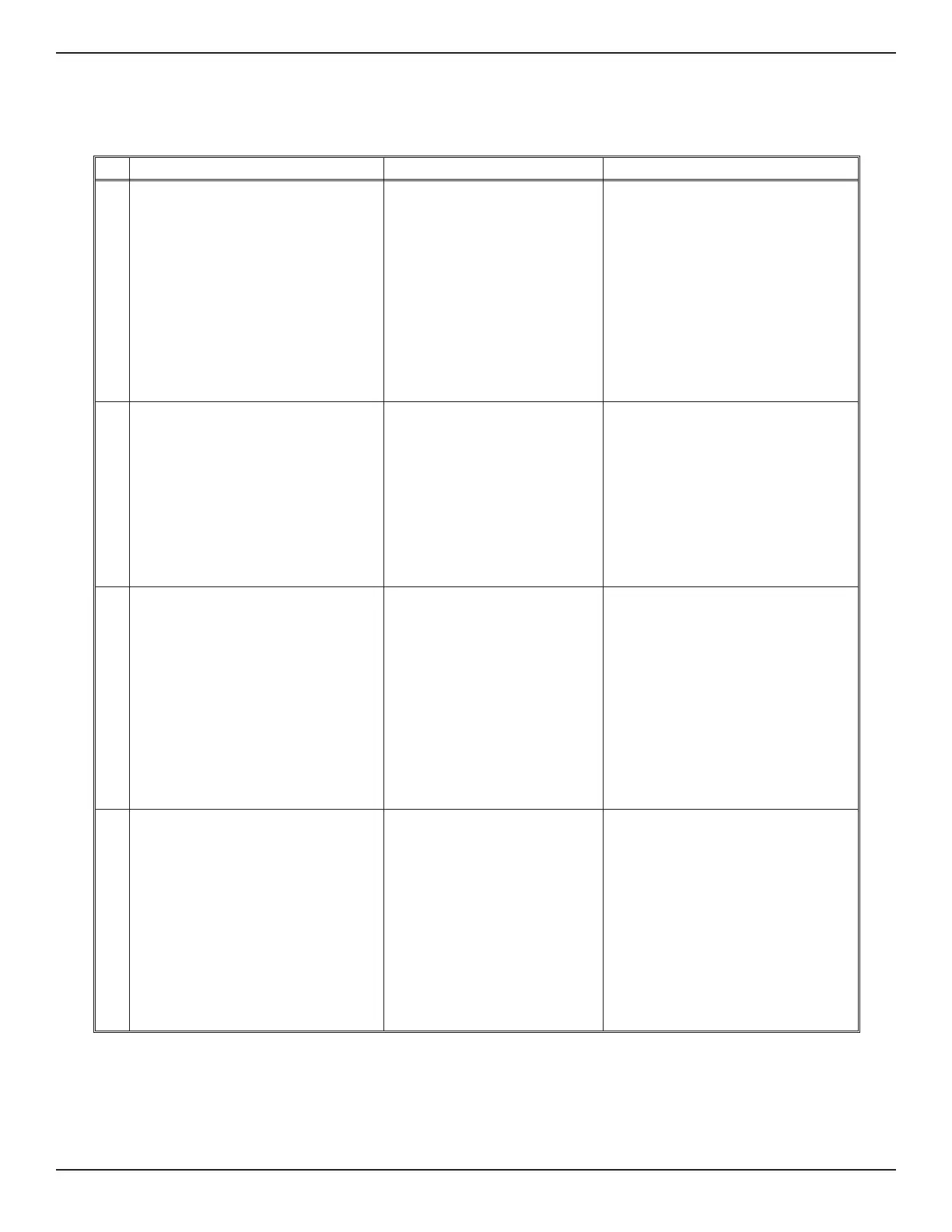

Table 5.1 continued...

Symptoms and Clues Possible Cause Try This

7 SYSTEM UNABLE TO COMMUN-

ICATE OVER THE GPIB

CLUE: Signals are not being

transferred from the GPIB board to

the rear panel of the PCS 400.

The GPIB address or

termination character is set

incorrectly.

----------------------

GPIB cable is disconnected at

the front of the electrical

module

Æ.

----------------------

The GPIB card is not properly

seated in the electrical

module.

Check and reset the GPIB

parameters from the front panel

keys.

-------------------------

Re-connect the cable.

--------------------------

Re-seat the GPIB card into its

mating connector.

8

SYSTEM UNABLE TO COMMUN-

ICATE OVER THE RS-232 PORT

CLUE: Signals are not being

transferred from the CPU board in

the electrical module to the rear

panel.

The RS-232 parameters are

not set up properly

----------------------

TheRS-232cableis

disconnected from the CPU

board

Ç .

----------------------

CPU board not seated.

Check and reset serial parameters

from the front panel keys.

-------------------------

Re-connect the cable. The red

conductor connects to pin 1, COM1.

--------------------------

Re-seat CPU board into its

connector.

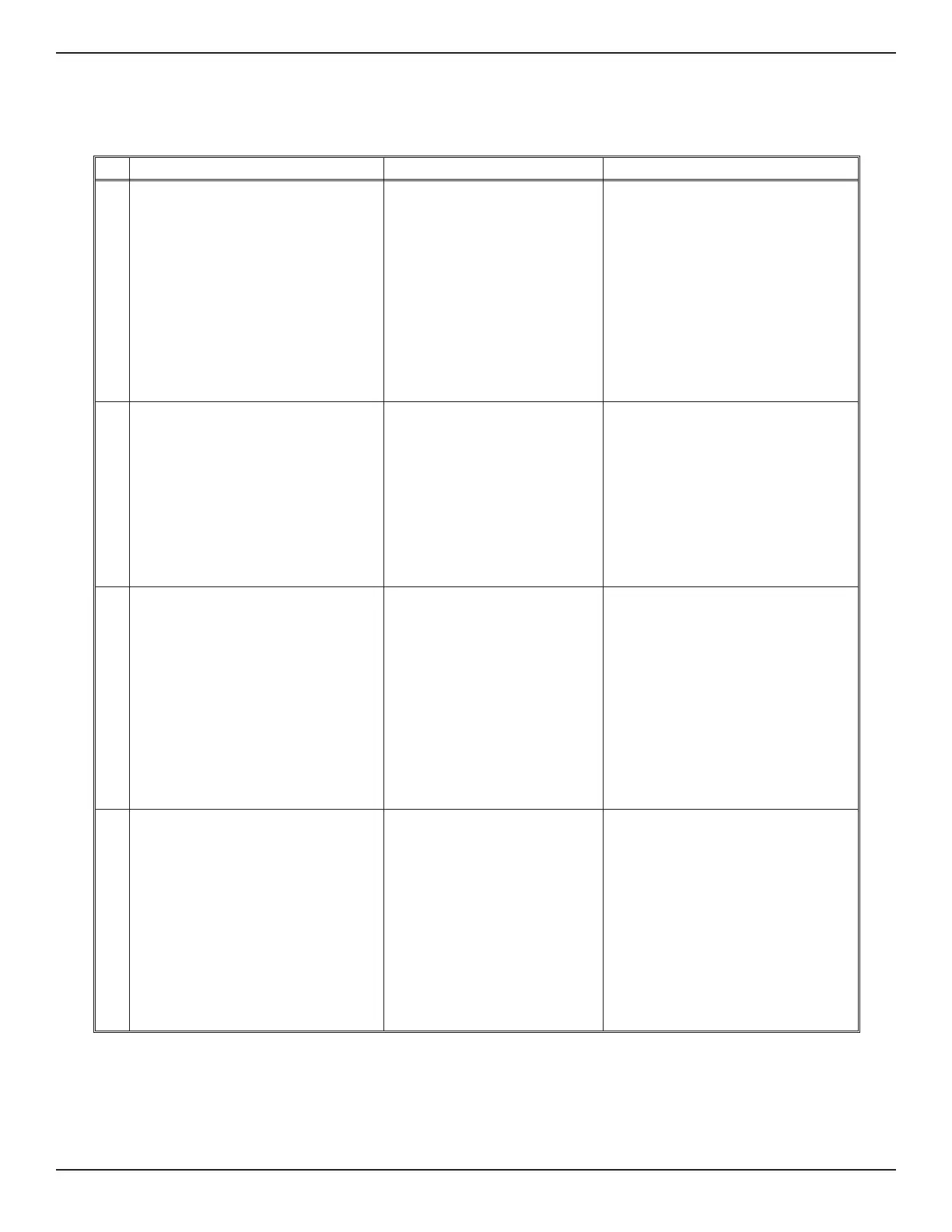

9

INACCURATE OR NO RE-

SPONSE TO THE SOURCE

PRESSURE TEST

CLUE: The auxiliary transducer on

the pneumatics module measures

the source pressure by opening

only the coarse supply solenoid. Its

calibrated analog output is read by

the electrical module and converted

to pressure.

Transducer cable is discon-

nected on the auxiliary

transducer board

or at the

50 pin connector

Ä on the

electrical module.

---------------------

The coarse supply solenoid

À is not connected or not

opening.

Re-connect the cable.

--------------------------

Run the solenoid test to determine

if the coarse supply solenoid valve

is operating.

10

TOP LINE OF DISPLAY SHOWS

ZEROS DURING BAROMETRIC

REFERENCE CALIBRATION,

BUT SHOWS BAROMETRIC

PRESSURE WHEN THE BARO-

METRIC SENSOR IS MADE

ACTIVE.

CLUE: The PCS 400 looks for a

specific transducer address during

barometric calibration.

Either the address on the Bar-

ometric Reference Sensor, or

the interrupt is improperly set.

Check that the address of the

Barometric Reference Sensor is set

to address 2 (W2) with no interrupt

(no jumper) on W8 or W9.

PCS 400 MAINTENANCE

www.mensor.com 5-5

Loading...

Loading...